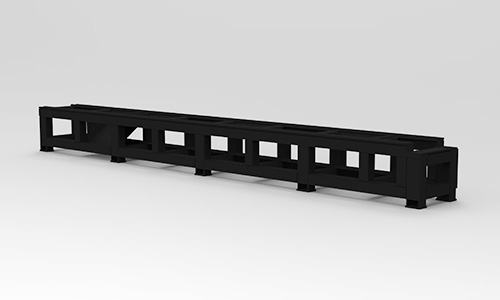

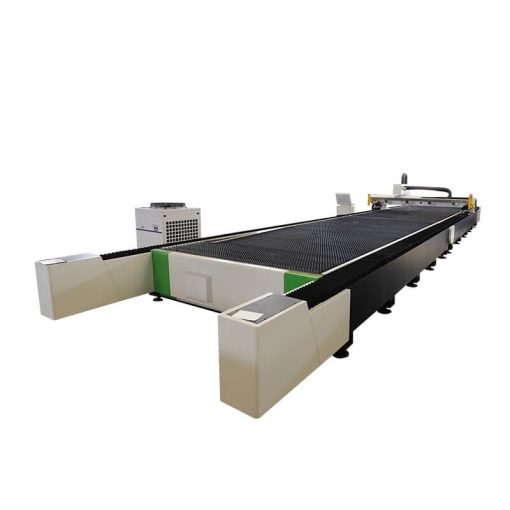

iGR-T Series

Laser Tube Cutting Machine

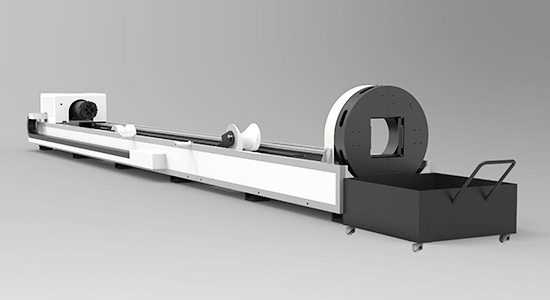

A laser tube cutting machine is a specialized CNC system designed specifically for processing pipes, tubes, and other cylindrical profiles. Unlike flat sheet laser cutters, tube cutting machines incorporate rotary systems that manipulate tubes during cutting, enabling the laser beam to access all surfaces around the circumference. The integration of linear and rotary motion creates three-dimensional cutting capabilities that produce complex profiles, holes, slots, notches, and connection details impossible with conventional tube cutting methods.

Modern systems combine high-power fiber lasers with sophisticated CNC controls, automated material handling, and intelligent software that transforms digital designs into precisely cut components ready for welding, bending, or assembly.

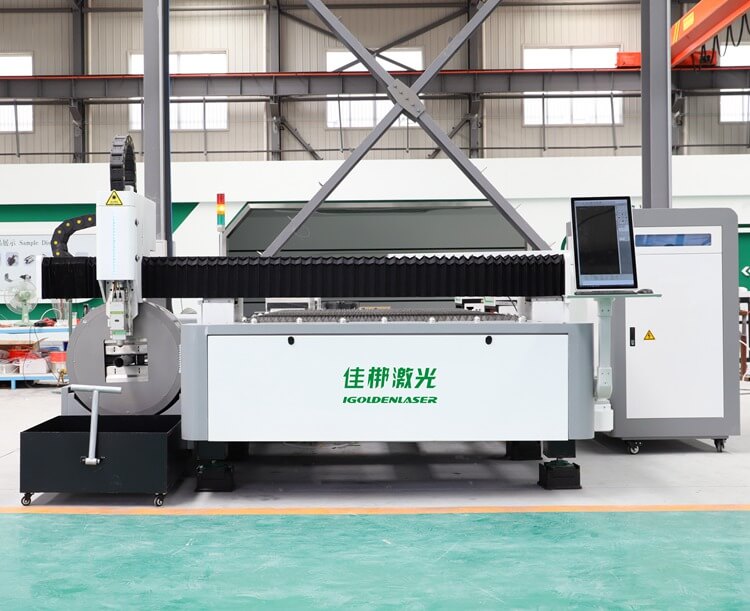

Tube laser cutting machine is specially designed for metal tube cutting laser cutting machine. It can cut round tubes, square tubes, oval tubes, rectangular tubes and irregular tubes. It is equipped with a special cutting operating system, the system is simple to operate, high precision, professional and stable, suitable for professional profile cutting, widely used in sports equipment, oil pipelines, chemical equipment and other industries.