Buyer Guide

Round Tube & Square Tube Laser Cutting Machine

These machines are specifically designed to handle both round and square tubes, making them suitable for a wide range of applications. Whether you need to cut round tubes for pipes or square tubes for structural components, these machines offer the flexibility to accommodate different tube shapes and sizes.

Round Tube & Square Tube Laser Cutting Machine

A fiber laser tube cutting machine is a type of industrial equipment used for cutting various types of tubes and pipes with high precision and efficiency. These machines utilize fiber laser technology, which involves using a high-powered laser beam generated by fiber optics to cut through the material.

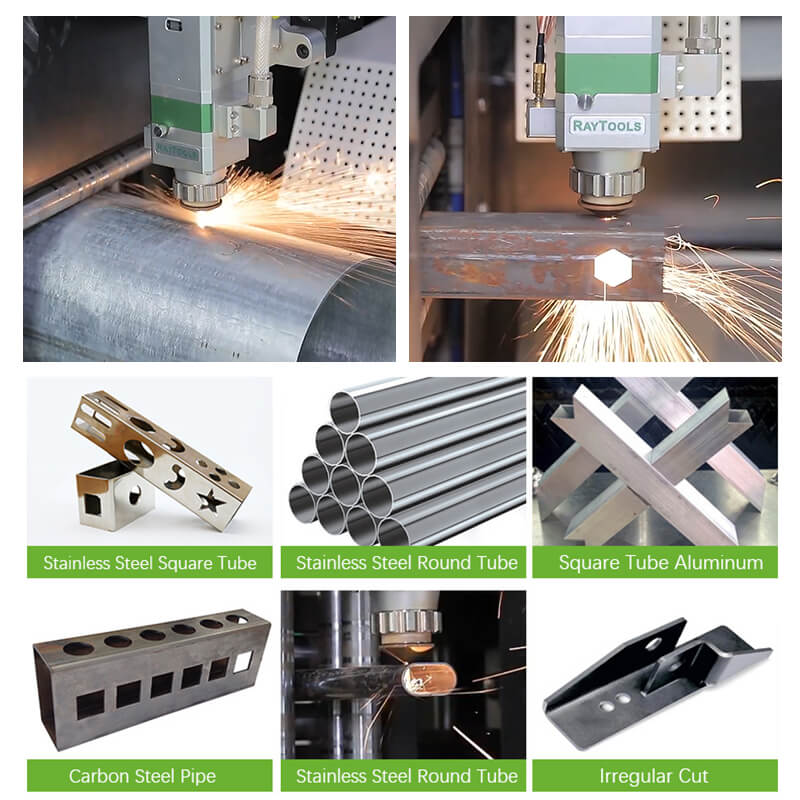

Metal tube laser cutting machine Especially for laser cutting metal tube of round, square, rectangular, triangle, oval, waist tube and other shaped tube & pipe. The tube outer diameter can be 20-200mm, length 8m.A round tube and square tube laser cutting machine is a specialized industrial equipment designed to cut both round and square tubes with high precision and efficiency using laser technology. It is capable of cutting various metals, including steel, stainless steel, aluminum, brass, and copper.

- It is equipped with a special cutting operating system, the system is simple to operate, high precision, professional and stable, suitable for professional profile cutting, widely used in sports equipment, oil pipelines, chemical equipment and other industries.

- Optional laser power 1000W,1500w 2000w,3kw,6000W; Optional countertop 6016/6024/6036; 3 meter tube and 6 meter tube are standard.

- Support customization

Automatic Loading and Unloading

Featuring advanced automation capabilities, the machine streamlines the cutting process with automatic loading and unloading systems. This enhances productivity and reduces manual intervention, leading to increased efficiency.

Tube Laser Cutting Machine Intelligent Control System

The pipe surface profile correction function can effectively compensate the regular cutting deviation for workpieces with stable deviation of the pipe surface, reduce the accuracy requirements for raw materials, and reduce waste.

Support single-sided centering, effectively solve the accuracy problem of the pipe hole position, and improve the accuracy of the distance from the edge of the hole position.

Support the centering of special steel, support the centering of various special steels such as L steel, channel steel, and I-beam, and improve the cutting accuracy of special steel.

The one-key alignment function of the tube head, using the cutting head to align the tube head, can effectively reduce the time of manual alignment and reduce the front-end waste of manual alignment.

The process of starting and closing the knife can solve the problem of high power at the starting point of cutting and burn to the opposite side, and solve the problem of leaving a small tail at the cutting position caused by the thin tube falling before cutting.

Pause the PLC and continue to process the end of the pipe, which can control the release of the middle chuck, improve the Y-axis movement stroke and cutting ability, and effectively reduce the tailings of the two chucks.

Laser cutting technology ensures precise and accurate cuts on both round and square tubes. The focused laser beam allows for fine and clean cuts with minimal distortion, resulting in high-quality finished products. These machines can achieve tight tolerances and produce complex shapes, angles, and patterns on the tubes.

Many round tube and square tube laser cutting machine come with advanced automation features to enhance productivity and streamline the cutting process. They can be integrated into automated production lines or equipped with loading and unloading systems for efficient material handling. Automation reduces manual intervention, minimizes downtime, and increases overall efficiency.

Product Configuration

| Name | Quantity | Manufacturer/Brand |

| Laser | 1 | MAX |

| Cutting head | 1 | RAYTOOLS |

| Bed | 1 | Pipe welding |

| Beam | 1 | Steel beam |

| Rack | 1 | TAIWAN YYC |

| Guide rail | 1 | TAIWAN HIWIN |

| Reduction | 1 | SHIMPO |

| Control cabinet | 1 | iGOLDENLASER |

| servo motor | 1 | FUJI |

| Control system | 1 | CypCut |

| Water chiller | 1 | Hanli/S&A |

Tube Laser Cutting Machine Applications

Round tube and square tube laser cutting machines find applications in various industries, including automotive, aerospace, furniture, construction, and metal fabrication. They are used to cut tubes and profiles for structural components, frames, exhaust systems, handrails, and more.

Fiber laser tube cutting machines can cut a wide range of materials, including metals such as steel, aluminum, brass, and copper, as well as various types of plastic and composite materials.

Can a laser cutting machine tube handle different materials and shapes?

And it’s not just the materials, but the shapes too. Whether you need round pipes for plumbing, square ones for frames, or rectangular tubes for structures, fiber laser tube cutter machine can cut them all. It’s perfect for jobs that need lots of different shapes.

CNC tube laser cutter is smart, too. It can change settings to cut different sizes and thicknesses. So, if you need a thin pipe for a lightweight job or a thick one for something heavy-duty, it’s got you covered. This is really important when you need pieces to fit together perfectly, like in a bike frame or a metal fence.

This tool is super helpful for a lot of industries. Car makers use it for parts. Airplane manufacturers need it for frames. And even furniture makers rely on it to cut metal for chairs and tables. The laser makes cuts that are clean and precise, which means less work to finish the part afterward.

In short, a laser cutting machine for tubes is like the Swiss Army knife for cutting metal. It’s quick, accurate, and can handle just about anything you throw at it.

What is a Pipe Laser Cutter and What Types Are Available?

A CNC pipe laser cutter precisely slices through metal tubes. It heats tubes to the point they melt or vaporize. You’ll find different types:

Three-chuck tube laser cutting machine: Ensures consistent cuts for many pipe shapes.

Automatic laser pipe cutting machine: Speeds up work with its automated loading and fast slag removal.

These machines work with materials like stainless steel and carbon steel, cutting in shapes from squares to ovals. Their power ranges from 1000w to 6000w.

They handle tubes from 20 to 380 mm in diameter and up to 30 mm thick. The advantages of a laser pipe cutting machine are: Precision: They cut accurately with little waste. Flexibility: They manage complex cuts, such as holes and notches, and shape beveled edges without additional steps. Utility: Industries that need bespoke pipe shapes, from construction to fitness equipment making, find them indispensable.

What are the benefits of using a CNC laser machine to cut pipes instead of old-fashioned methods?

Using a CNC laser to cut pipes is way better than the old ways of cutting metal. Here’s why:

Super accurate: The laser is incredibly precise. It can make really exact cuts that older tools just can’t match. This is really important when you need pieces that fit together perfectly.

Clean cuts: The edges it leaves are smooth and neat. You won’t see any rough spots or need to do a lot of cleaning up afterward, which you often have to do with traditional cutting.

Quick work: It’s a lot faster than old-school cutting. This means you can do more work in less time, saving money and meeting tight deadlines.

Complex shapes: With a laser, you can make really complicated cuts without having to change tools. It’s all done with the same machine, which saves a lot of hassle.

CNC magic: The computer control (that’s what CNC stands for) means you can cut intricate designs easily. Once you tell the computer what to do, it handles the rest, making sure every cut is just right.

Less waste: Since the laser is so precise, there’s not a lot of leftover metal scraps. This means you use more of the material you have, which is good for the planet and your pocket.

In short, a CNC laser pipe cutter is like a high-tech, super-efficient scissors for metal. It makes the job of cutting metal faster, cleaner, and more precise, which is why it’s a big deal in the world of metalwork.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.