No products in the cart.

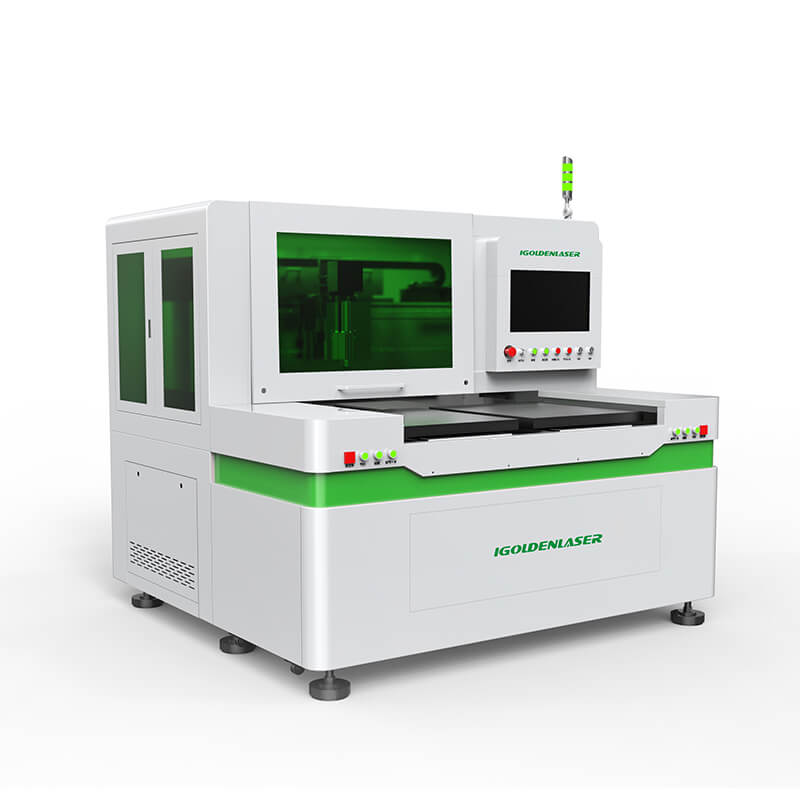

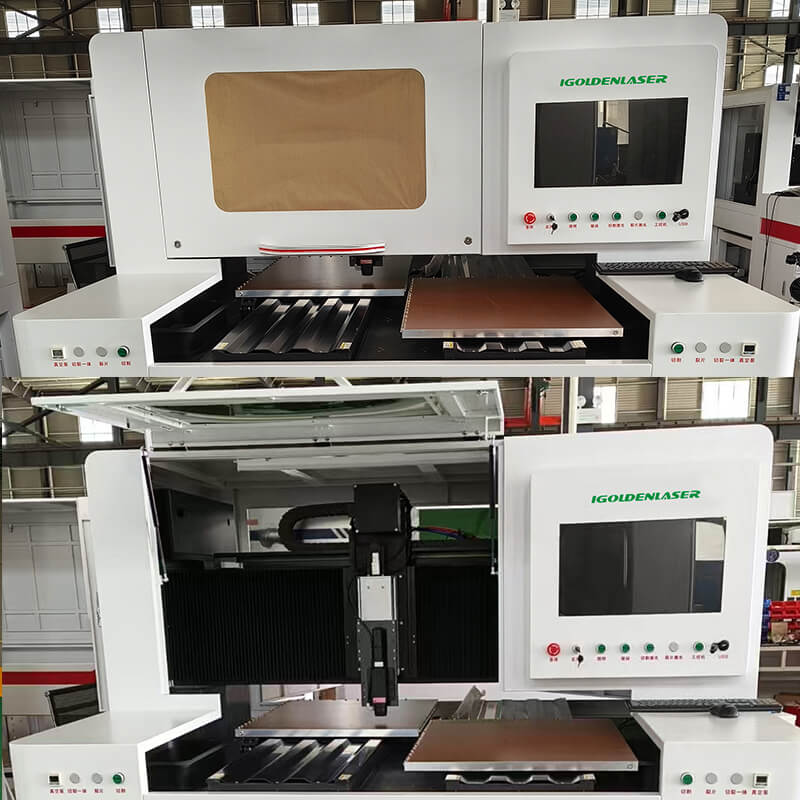

Glass Laser Cutting Machine

Picosecond laser glass cutting machines the epitome of sophistication in glass artistry. Harnessing the power of ultrashort laser pulses measured in picoseconds, these machines sculpt glass with unparalleled precision and detail, allowing artisans to create intricate designs and delicate patterns that defy traditional cutting methods. Witness the magic unfold as each cut is executed with flawless clarity and finesse, elevating glass art to new heights of beauty and sophistication.

As a non-contact machining method, picosecond laser cutting effectively prevents microcracks and chipping. Its ultra-short pulse duration allows cutting to be completed before heat can diffuse, resulting in virtually no residual stress. This greatly enhances the mechanical strength of glass edges and ensures superior cut quality.

A picosecond laser emits ultrashort pulses measured in trillionths of a second (10⁻¹² s). Unlike traditional lasers that generate heat and micro-cracks, a picosecond laser cuts glass through a “cold ablation” process.

This means:

-

No thermal damage

-

No micro-cracks

-

Smooth edges without polishing

-

Extreme cutting accuracy (±1μm)

It is widely used for precision glass cutting applications that require tight tolerances and flawless quality.