Buyer Guide

Can a Laser Cutter Cut Glass & Plexiglass

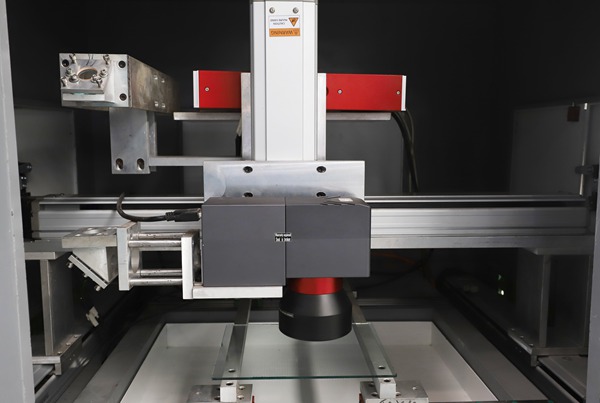

A laser glass cutting machine is a specialized piece of equipment designed to cut and engrave glass materials with high precision. It uses a laser beam to create controlled fractures in the glass, resulting in accurate and intricate cuts. Glass & plexiglass laser cutting machine are commonly used in industries where glass cutting requires extreme precision and automation, such as for the production of glass components for electronics, displays, and optics.

The equipment uses high-energy and high-precision lasers to cut/drill glass materials. High-definition image alignment and professional customized operation software control system make the production efficiency higher, the repeated positioning more accurate, and the operation easier. The equipment has been widely used in instrumentation glass/photovoltaic glass/mobile phone glass/medical instrument/vehicle display/panel display glass and other industries. This equipment is mainly composed of marble frame sheet metal, motion gantry module, vacuum adsorption platform CCD alignment structure, panel fixture, laser system, manual unloading platform, electric control system, etc.

With an as cut edge roughness at < 2µm, in most cases the cut glass can be used for subsequent processing without additional intermediate steps for time and cost consuming post-processing. Glass pieces cut with IGOLDENLaser Technologies’ unique laser glass cutting process have superior break strength behavior, compared to items cut by other laser methods and conventional mechanical glass cutting processes.

Glass Laser Cutter Features:

- Laser non-contact processing, no hard damage to the product;

- No water cooling processing, environmental protection and no pollution; no consumables, support 7*24 hours of operation, long-term use and stability;

- The processing speed is fast, the efficiency is high, the edge collapse is small, and the power consumption is low;

- Using picosecond laser, ultra-short pulse processing without heat conduction, suitable for high-speed cutting and drilling of any organic or inorganic materials

- CCD visual pre-scanning and automatic target positioning, accurate positioning

- Support a variety of visual positioning features, such as cross, solid circle, hollow circle, L-shaped right-angle edge, image feature points, etc.

- Automatic cleaning, visual inspection and sorting, automatic loading and unloading and other devices can be customized.

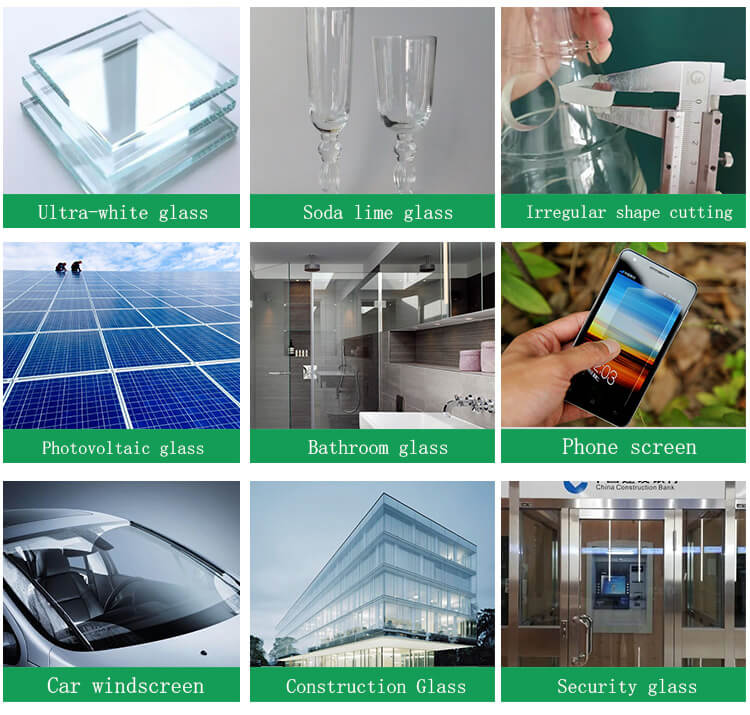

Application range:

- Gem & glass cover plate / optical glass / semiconductor package chip / sapphire / silicon wafer / ceramic substrate and other brittle materials, heat-sensitive polymer / inorganic materials, micro drilling / cutting

- LCD panel cutting

- Optical lens shape cutting

- Organic cover plate and optical lens shape cutting

- Novel flexible display or fine electronic circuit etching/cutting of organic/inorganic materials.

What Types of Lasers Are Good for Cutting Glass?

You are likely to stumble upon one of the two common types of laser cutters − pulse or continuous wave. Each one has its characteristics. Thus, it pays to take a closer look. Pulse lasers compress the cutting energy into short bursts.

That allows the machine to reach a high temperature and energy density. In turn, you get less deformation and high-precision cuts. But to achieve the pulse, these units have high-end electronics and materials, which makes them more expensive than continuous-wave. As given in the name, continuous-wave lasers deliver an unobstructed flow of energy to cut.

The glass gets heated until the material literally evaporates, but this might cause deformation with some types of glass.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.