Laser Knowledge

What Tubes Can a Tube Laser Cutting Machine Cut?

Tube laser cutting machines have revolutionized metal fabrication by offering unprecedented precision and versatility in cutting tubular profiles. Understanding which tubes and profiles these machines can process is essential for manufacturers looking to invest in this technology or expand their production capabilities.

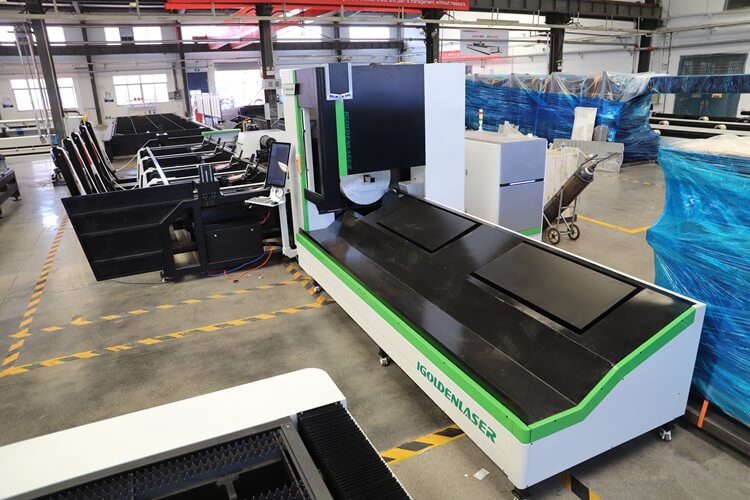

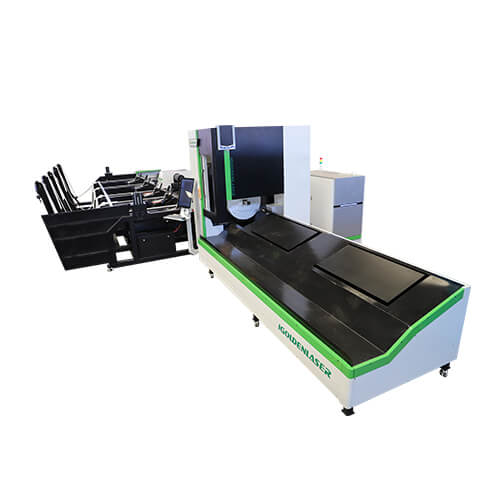

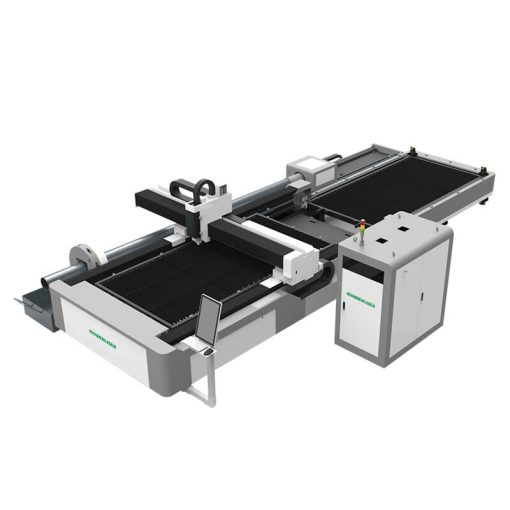

Tube Laser Cutting Machine

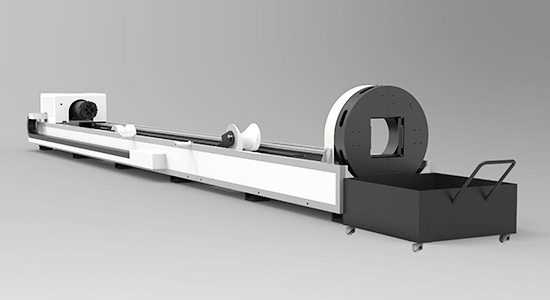

A tube fiber laser cutting machine is a type of laser cutting equipment designed to cut various types of metal tubes and pipes with high precision and speed. The T series has two specifications, 6016 model and 6024 model. The 6016 model can cut round and square tubes with a length of 6 meters and a max. diameter of 100 mm. The 6024 model can cut round and square tubes with a length of 6 meters and a max. diameter of 240 mm. IGOLDENLASER continuously optimizes the appearance, structure and configuration of the T series according to market customer feedback, and strives to provide each customer with a high-performance, cost-effective laser cutting machine that meets the processing needs.

Laser Cutting Machine

Laser Cutting Machine

Laser Cutting Machine

Laser Cutting Machine

Laser Cutting Machine

Laser Cutting Machine

Metal Sheet and Pipe Laser Cutting Machine with Exchange Worktable

Laser Cutting Machine

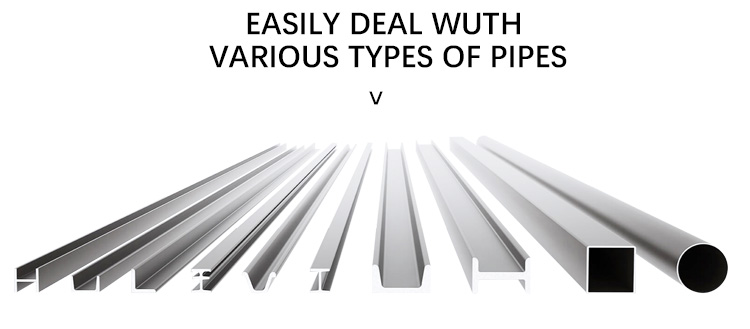

Tube shapes and profiles that can be cut

Modern tube laser cutting machines can process a wide range of tube shapes and structural profiles. From standard round and square tubes to complex open sections and custom extrusions, laser cutting enables precise contours, holes, and bevels in a single setup.

| Tube Shape / Profile | Typical Applications |

|---|---|

| Round tubes (Ø20–600 mm) | Pipelines, furniture frames, bicycle frames, medical equipment |

| Square & rectangular tubes | Building columns, machine frames, warehouse racking |

| Oval & elliptical tubes | Fitness equipment, exhaust systems, decorative structures |

| Open section profiles (C, U, L) | Brackets, trusses, support structures |

| H-beams & I-beams | Shipbuilding, bridges, heavy machinery |

| Special extruded sections | Agricultural machinery, architectural components |

Deep processing of structural profiles and heavy-duty shapes

Modern industrial demands have extended beyond closed-section tubes to complex structural profiles. H-beams, I-beams, angle steel, and channel steel form the backbone of construction and heavy industry, where processing quality directly impacts structural safety.

Traditional processing workflows typically involve multiple machines—saws, drilling presses, and milling machines—requiring material handling between stations. Integrated tube laser systems consolidate these operations into a single setup, dramatically improving efficiency and accuracy.

Processing open-section profiles presents unique challenges:

- H-beam processing requires the laser head to navigate between flanges and webs while maintaining consistent focal point positioning and executing collision-avoidance algorithms

- Angle and channel steel demand adaptive centering systems to compensate for asymmetric cross-sections and prevent dimensional errors during rotation

- Custom extruded profiles with complex cross-sections benefit from 3D scanning feedback and six-axis control systems, enabling millimeter-level precision alignment

Maximum processing capabilities typically include:

- Tube diameter: up to 530-600mm

- Length: up to 12 meters (depending on machine configuration)

- Weight capacity: up to 1.5 tons for heavy-duty four-chuck systems

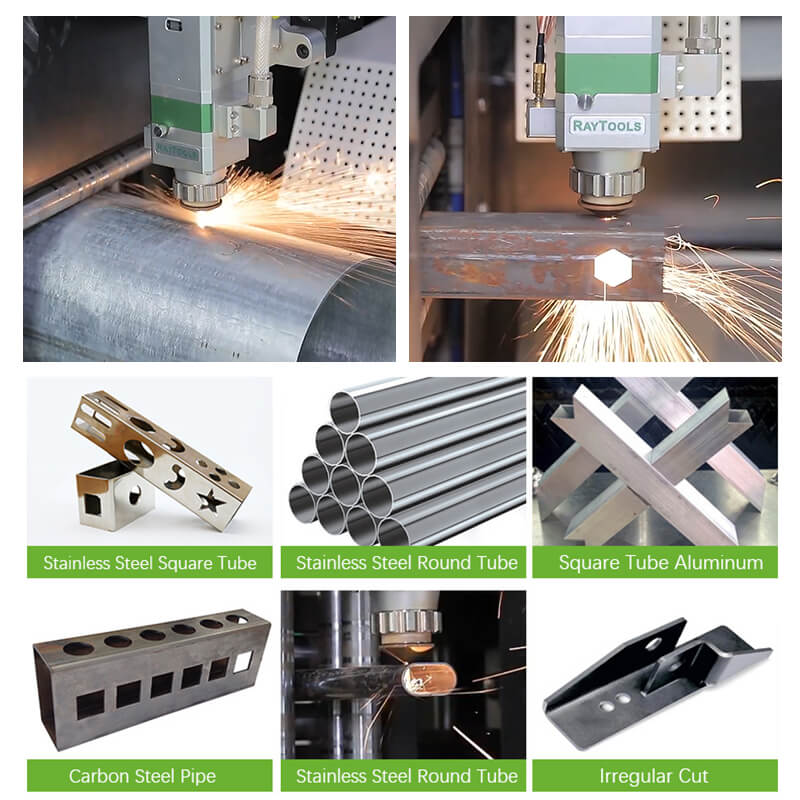

Materials that can be cut by tube laser cutter

Tube laser cutting machines are primarily designed for metal processing. Different materials respond differently to laser energy depending on absorption, reflectivity, and thermal conductivity.

- Carbon steel is the most commonly cut tube material. It offers high laser absorption and fast cutting speeds, making it suitable for a wide range of industrial applications.

- Stainless steel is widely used for tube laser cutting and delivers clean, oxide-free edges when nitrogen assist gas is applied, especially for decorative or visible parts.

- Aluminum alloys can be cut efficiently with higher laser power and proper gas control. Due to their high reflectivity and thermal conductivity, stable optical protection is required.

- Copper and brass are more challenging materials because of their extremely high reflectivity. With modern high-power fiber lasers and anti-reflection systems, thin to medium wall thicknesses can be processed reliably.

- Galvanized steel tubes can be laser cut, but zinc vapor management and effective fume extraction are essential to protect both equipment and operators.

- Titanium alloys are typically used in high-value applications. Laser cutting is feasible when high-purity inert gas is applied to maintain edge quality and prevent oxidation.

Material Types for Tube Laser Cutting

Carbon Steel Tubes

Carbon steel represents the most commonly cut material on tube laser machines. Mild steel tubes from 0.5mm to 25mm wall thickness process efficiently across all profile shapes. The material’s favorable laser absorption characteristics enable fast cutting speeds and excellent edge quality.

Applications range from structural components and automotive parts to furniture frames and industrial equipment. Carbon steel’s affordability and availability make it the go-to choice for high-volume production.

Stainless Steel Tubes

Stainless steel tubes in grades 304, 316, and 430 are frequently processed for food processing equipment, medical devices, and corrosion-resistant applications. Wall thicknesses from 0.5mm to 15mm cut cleanly with minimal heat-affected zones, preserving the material’s corrosion resistance properties.

Tube laser cutting produces burr-free edges on stainless steel, often eliminating deburring operations. This is particularly valuable for hygienic applications where smooth surfaces are mandatory.

Aluminum and Aluminum Alloys

Aluminum tubes require specific laser parameters due to the material’s high reflectivity and thermal conductivity. Modern fiber laser systems handle aluminum profiles from 0.8mm to 12mm wall thickness effectively. Common alloys include 6061, 6063, and 5052 used in transportation, electronics enclosures, and lightweight structures.

Cutting aluminum tubes produces minimal dross and requires less assist gas than traditional methods. The non-contact nature of laser cutting prevents material deformation common with mechanical processes.

Copper and Brass Tubes

Copper and brass tubes, despite their high reflectivity, are successfully cut with contemporary fiber laser technology. These materials are essential for plumbing, electrical applications, and decorative elements. Wall thicknesses up to 6mm can be processed, though cutting speeds are slower than with steel.

Special attention to laser power and frequency optimization ensures clean cuts in these challenging materials. Applications include heat exchangers, musical instruments, and architectural details.

Titanium and Exotic Alloys

High-value aerospace and medical applications utilize titanium tubes that tube laser cutting machines process with exceptional precision. Wall thicknesses from 0.5mm to 8mm are typical for these expensive materials where minimizing waste is crucial.

The laser’s precision and minimal heat input preserve titanium’s material properties while enabling complex geometries impossible with conventional cutting methods.

Tubes that cannot be cut

Not all tube materials are suitable for laser cutting. Some materials may cause serious safety hazards, equipment damage, or poor cutting quality.

Materials that should NOT be laser cut include:

-

Toxic gas–releasing plastics

Such as PVC, PTFE, and vinyl. These materials release corrosive or highly toxic gases during laser cutting, which can damage equipment and pose serious health risks. -

Highly flammable plastics and foams

Materials like polystyrene foam and thick polycarbonate ignite easily and may cause uncontrolled burning. -

Fiber-reinforced composites

Carbon fiber and fiberglass tubes release hazardous fumes and suffer from poor edge quality due to uneven laser absorption. -

Transparent materials

Glass and clear acrylic do not absorb fiber laser energy effectively and cannot be cut. -

High-oil natural materials

Oily wood tubes are extremely flammable and contaminate optical components.

Recommended alternatives include mechanical sawing, waterjet cutting, CO₂ lasers (for some plastics), or specialized composite cutting tools.

Important safety notes:

- PVC and chlorine-containing materials are the absolute “red line” in laser cutting. The hydrochloric acid produced corrodes machine rails, ball screws, precision lenses, and CNC systems, causing permanent damage

- ABS cutting releases hydrogen cyanide gas, threatening operator life even at low concentrations

- Galvanized steel requires careful processing as zinc vapor can contaminate optics and pose respiratory hazards

Material thickness limitations:

Even suitable materials have practical limits:

- Thick copper/aluminum(>10mm) may exceed cutting capacity of lower-power systems

- Carbon steel beyond 25-40mm requires ultra-high power lasers (10kW+)

- Tube diameter exceeding chuck capacity (typically >530-600mm) cannot be processed

Size and Dimension Capabilities

Diameter Range

Entry-level tube laser cutting machines typically accommodate tubes from 10mm to 120mm diameter. Mid-range systems extend this to 220mm diameter, suitable for most industrial applications. Large-capacity machines process tubes up to 300mm or even 400mm diameter for specialized heavy industry requirements.

The maximum diameter capability significantly impacts machine price and footprint. Assess your actual production requirements to select appropriate capacity without over-investing.

Length Capacity

Standard tube laser cutting machines handle material lengths from 3 meters to 6 meters as the industry norm. Extended models accommodate 9-meter or 12-meter tubes for specialized applications like structural steel fabrication and pipeline components.

Wall Thickness Range

Thin-wall tubes starting at 0.5mm can be cut without deformation using proper parameter optimization. Typical production ranges extend from 1mm to 12mm wall thickness for most materials.

Wall thickness affects cutting speed, assist gas consumption, and achievable detail level. Understanding your thickness requirements helps specify appropriate laser power.

Technical Considerations and Limitations

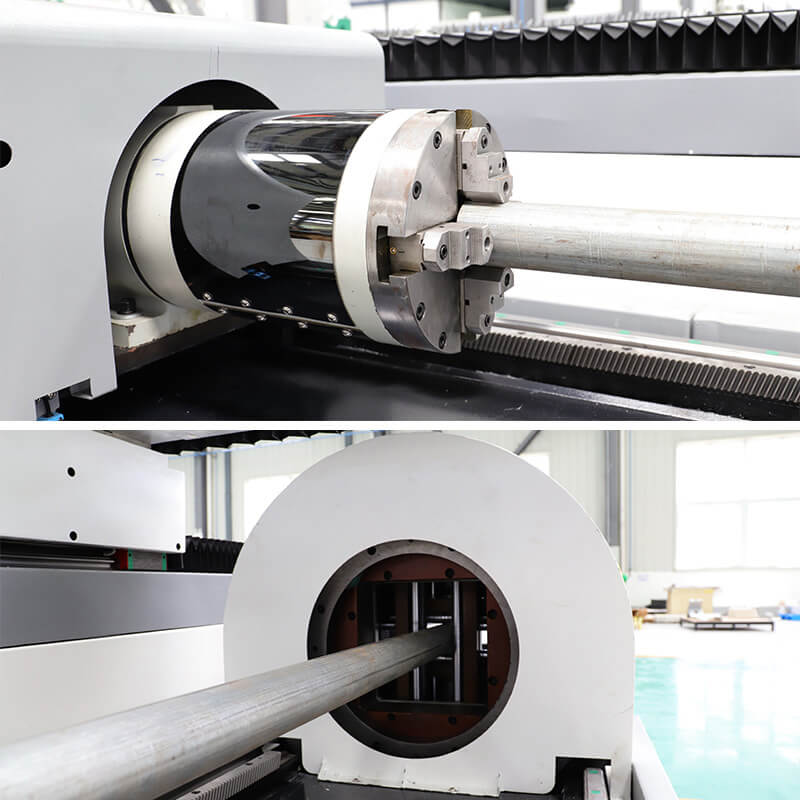

Chuck and Clamping Systems

The chuck system determines which tube profiles and sizes a machine can process. Three-jaw chucks handle round tubes and adapt to hexagonal profiles. Specialized multi-jaw or contoured chucks accommodate square, rectangular, and custom profiles.

Cutting Accuracy and Tolerances

Tube laser cutting machines achieve positioning accuracy of ±0.1mm and cutting tolerances of ±0.15mm on quality systems. This precision enables direct assembly without secondary machining for many applications.

Accuracy depends on tube quality, material type, and cutting parameters. Thin-wall tubes or materials with high thermal expansion require special consideration to maintain tight tolerances.

Production Speed and Efficiency

Cutting speed varies dramatically based on material, thickness, and detail complexity. Simple cuts in thin carbon steel tubes may reach speeds of 30-40 meters per minute. Complex patterns in thick stainless steel reduce speeds to 2-3 meters per minute.

Automatic loading and unloading systems maximize productivity by minimizing non-cutting time.

Applications Across Industries

Automotive manufacturers use tube laser cutting for exhaust systems, chassis components, and seat frames. The furniture industry creates complex joints and decorative patterns in tubular furniture frames. Construction and architecture leverage the technology for structural elements, handrails, and curtain wall components.

Fitness equipment manufacturers cut and shape tubes for exercise machines and weight equipment. Agricultural equipment, material handling systems, and aerospace components all benefit from tube laser cutting precision and efficiency.

Why Choose iGoldenLaser for Tube Cutting Solutions

iGoldenLaser offers comprehensive tube laser cutting machines capable of processing all standard profiles and materials discussed in this guide. Our systems range from compact models handling tubes up to 120mm diameter to industrial machines processing 300mm profiles with lengths up to 12 meters.

Advanced fiber laser sources deliver consistent performance across carbon steel, stainless steel, aluminum, and exotic materials. Intuitive control systems with 3D CAD/CAM integration simplify programming even for complex geometries. Automatic loading systems and integrated part sorting maximize productivity.

Our engineering team provides application support, helping customers optimize cutting parameters for their specific materials and profiles. Comprehensive training ensures operators achieve maximum machine capability from day one.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.