Buyer Guide

Laser Cutter and Engraver for Sale and Buying Guide

Laser cutting machines are classified into fiber and CO2 laser machines based on different light sources. Depending on various styles and appearances, they are identified into handheld, portable, mini, small, tabletop, benchtop and desktop. The most popular cutting tables include 2×3, 2×4, 4×4, 4×8, 5×10, 6×12 based on the workbench sizes. Before buying, take some measurements of your workshop space to ensure that it will fit, and buy the right table kit. The most common cutting systems are divided into 3 axis, 4th axis (rotary axis), 4 axis, 5 axis and 3D robotic types. According to industry applications, you can meet flatbed cutting tables, tube cutters, home cutting tools, hobby cutting kits, die cutters, profile cutting machines, and industrial cutting systems. In terms of cutting materials, you can define them as cutters for metal, wood, fabric, leather, paper, acrylic, plastic, foam, paper and more.

Laser Cutter

Fiber laser cutter is a CNC laser cutting system for metal, which is with high cutting quality, high cutting speed, high cutting precision and high cutting efficiency. It is suitable for most of of metal cutting and the fiber laser cutting machine is your good partner in metal processing. Equipped with different power (from 1,000W to 30,000w), it is used to cut metal materials with different thickness, such as stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron, etc. Fiber laser cutting machine is also called fiber laser metal cutting machine, fiber laser cutting machine, fiber laser cutting system, fiber laser cutting equipment, metal laser cutting machine, fiber optic laser cutter, laser metal cutter, laser cutter machine for metal, CNC laser cutter, CNC laser cutting machine, cnc laser metal cutter, fiber optic laser cutting machine.

A fiber laser cutter is an automated metal cutting machine that works with a CNC controller drived by CAM software to instruct a laser beam of 1064nm to cut out shapes and outlines from metal plates, pipes, rods and strips according to the layout file designed by CAD software to finish a metal fabrication project. It is a fine precision cutting tool for both sheet metals and tubes, as well as flat and beveled metal profiles. With a robotic arm, personalized 3D metal cuts are easily created. Non-contact cutting will not damage the substrate with smaller thermal influence of spot irradiation area. Fiber laser cutting machines are capable of cutting metals as thin as 1 mm and as thick as 200 mm, with powers ranging from 1,000 watts to 60,000 watts, and a maximum speed of more than 120 meters per minute. Fiber lasers can handle everything from hard metals (such as stainless steel, mild steel, carbon steel, spring steel, silicon steel, iron and alloy) to highly reflective metals (such as aluminum, gold, silver, copper and brass), which make them popular for both home and commercial use.

Fiber Laser Cutter

Laser cutter machine is a laser processing machine tool that is mainly used to cut plates into workpieces of the desired shape. Equipment that uses the thermal energy of a laser beam to achieve cutting.

iGOLDENLASER is a professional supplier of fiber laser cutting solutions. Our equipment includes Flatbed laser cutting machine, Plate&tube laser cutting machine, Protective laser cutting machine, Exchange-worktable laser cutting machine, metal pipe laser cutting machine.

Laser power range: 1000w/1500w/2000w/3000w/4000w/6000w/8000w/10000w/12000w.

Fiber laser source based CNC laser cutting machine for metal has a good ability and high speed for metal cutting, such as steel, stainless steel. If the metal thickness is below 4.0mm, this kind CNC metal laser cutter has a cutting speed of 2-3 times as a co2 laser machine. The fiber laser cutting machine is a flatbed mechanical device that uses a fiber laser to output a high-energy density laser beam, which instantly melts and vaporizes the area illuminated by the ultra-fine focus spot on the work piece, and moves the spot irradiation position through a numerical control mechanical system, thereby achieving cutting. It has the advantages of fast cutting speed, high precision, small area of heat affected area, stable performance, guaranteed continuous production, not easy to deform, smooth and beautiful cut seam, and no need for subsequent processing.

How does the fiber laser cutting machine work?

Through the numerical control system, the optical fiber laser cutting machine is with an optical fiber laser generator, which dopes the pump material into the optical fiber and couples the laser of specific wavelength emitted by the semiconductor laser to make the optical fiber produce laser. And then, the optical fiber laser cutter converges the laser beam into a small-diameter spot to form a high-energy density and extremely bright beam, which will act on the cut metal to make the metal temperature at the laser irradiation point rise sharply and reach the vaporization temperature instantly, causing evaporation and forming holes. The laser cutting machine takes this as the starting point and makes the fiber laser beam move relative to the workpiece according to a certain trajectory according to the sha

How to choose the right laser cutter machine?

- Processing materials and business requirements

First of all, we should consider our business scope, the thickness of the cutting material, the material that needs to be cut and then determine the size of the equipment that needs to be purchased and the size of the worktable. At present, the power of the laser cutting machine on the market is between 500w and 6000w. The scale of the workbench manufacturer can be customized according to customer needs.

- Selection of suppliers (manufacturers)

After confirming the demand, we can understand and check the performance and basic parameters of the machine through various channels. Choose some strong and competitive manufacturers for early communication and samples, and then we can conduct on-site inspections, the price of the machine, and the machine Training, payment methods, after-sales service, etc. are discussed in more detail.

- Laser power

When choosing the performance of a laser cutting machine, you should fully consider the environment. For example, we often cut metal plates below 6mm, and then choose a 500W-700W laser cutting machine to meet production needs. If cutting more than 6mm Materials, you need to consider the use of larger power machines, which is more conducive to the cost control of enterprises.

- The core part of the laser cutting machine

When selecting some important parts of the laser cutting machine, we also need to pay special attention. Especially the laser generator, laser cutting head, servo motor, guide rail, water tank, etc., we must distinguish whether it is made in China or imported. All these factors directly affect the laser The cutting speed and accuracy of the cutting machine.

- Equipment quality and stability in use

Now the product development cycle is very short, and the update and replacement are getting faster and faster. How to guarantee customer orders, maintain the company’s reputation, and improve the company’s competitiveness is also an arduous task for every operator. Therefore, choose and purchase stable processing Equipment is the prerequisite and foundation. It is necessary to choose as much as possible a brand with a high market share, a complete after-sales service system, many after-sales service outlets and long-term market inspections. Without after-sales service, we cannot covet cheap products and buy inferior products. This will have a huge impact on the company’s production.

- After-sales service

The after-sales service of each manufacturer varies greatly, and the warranty time is uneven. In the after-sales service, we should not only provide customers with an effective daily maintenance plan but also establish a professional training system to help customers get started as soon as possible.

What are the characteristics of fiber laser cutting machine?

1. The electro-optic conversion efficiency of fiber laser metal cutting machine is high, and the conversion efficiency is more than 30%. Low power fiber lasers do not require cooling chiller. The air cooling system on the fiber laser cutting system can greatly save the power consumption during operation of the fiber laser metal cutting machine, and it will save the operation cost and achieve the highest production efficiency.

2. When the fiber laser works, it only needs the lowest maintenance cost, and no need the additional gas to the laser, so the fiber laser metal cutting machine will be with low cost for the operation and the maintenance.

3. The fiber laser metal cutting machine adopts semiconductor modular and redundant design. There is no optical lens in the resonant cavity, so the fiber laser metal cutting machine no need the no start-up time, no adjustment, maintenance and high stability. It reduces accessory costs and maintenance time.

4. The output wavelength of fiber laser metal cutting machine is 1.064 μ m, which is only 1 / 10 of CO2 wavelength. The output beam has and high power density and good laser beam quality. So it is very conducive to the absorption of metal materials.

5. The optical transmission of the whole fiber laser metal cutting machine adopts optical fiber, which does not need complex light guide systems such as mirrors. The optical path is simple, the structure is stable, and the external optical path is maintenance free.

6. The cutting head contains protective lenses, so that the consumption of expensive consumables such as focusing lenses is very small.

7. Light is output through optical fiber, which makes the design of mechanical system of the fiber laser metal cutting machine very simple and easy to integrate with robot or multi-dimensional working table.

8. After the laser is equipped with a shutter, multiple machines can work simultaneously through optical fiber shunting and multi-channel. The function expansion is convenient and the upgrade is convenient and simple.

9. The optical metal laser cutter has the advantages of small volume, light weight, movable working position and small floor area.

Laser Engraver

Laser engraver machine, as the name suggests, is advanced equipment that uses a laser to engrave materials that need to be engraved. It has many advantages: smooth incision, non-contact cutting, high-speed engraving, accurate engraving, and good results.

The laser source of the co2 laser engraving machine is a glass laser tube, which can be upgraded to a co2 metal radio-frequency tube.

The common power of the laser tube is 40w/60w/80w/100w/130w/150w/170w/220w/260w.

CO2 Laser Engraver

Laser engraving is the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. It has high precision, fast cutting, not limited to the limitation of cutting patterns, automatic layout saves material, and smooth cutting, Low processing cost and other characteristics, will gradually improve or replace the traditional engraving process equipment.

What is the application range of the laser engraver machine?

What to do with a Laser Cutter Engraver? If I buy a laser cutter, can CNC laser cutter engraver do what CNC laser designs? IGOLDENLASER provides a variety of CNC laser cutting engraving equipment. All these best laser machines can help you realize your CNC laser solutions.

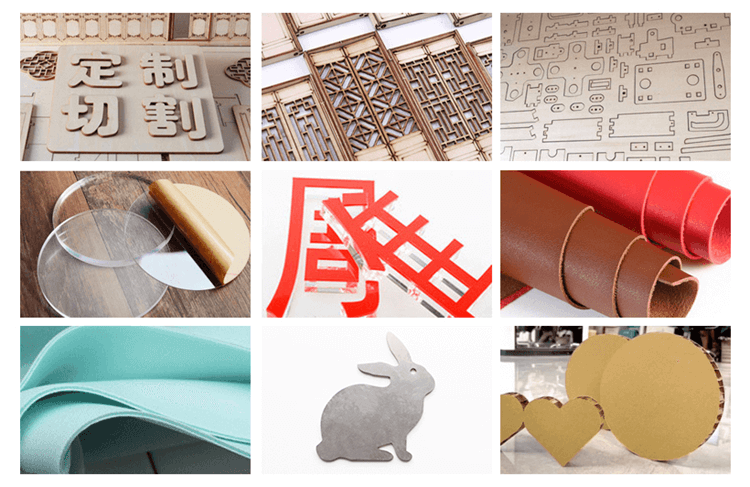

Laser processing can be performed on non-metallic materials and metal sheets such as acrylic, bamboo, wood, crystal, horn, paper plate, plexiglass, glass, marble, cloth, leather, rubber, plastic, paper, film, etc.

The carbon dioxide laser engraving machine is suitable for most non-metallic materials, such as paper packaging, plastic products, label paper, leather cloth, glass ceramics, resin plastic, bamboo and wood products, PCB boards, etc.

Clothing, embroidery, cloth toys, furnishing fabrics, handbags, gloves, toy industry leather, leather cutting and surface carving. Crafts, models, advertising, decoration, electrical appliances, acrylic panels, medium-density decorative panels in the plastic industry, etc. Precision cutting of non-metallic thin plates.

Kitchenware metal sheet cutting, advertising characters, large format truncation, clothing proofing, leather industry, footwear, decoration industry, furniture industry, packaging and printing industry, model industry, craft gift industry, etc.

How to choose the right laser engraver machine?

- Material to be carved:

Determine the type of material to be engraved. At present, the CNC laser engraving machine on the market can be roughly divided into non-metal laser engraving machine and metal laser engraving machine. The former is specially used for engraving and cutting of non-metallic materials, while the latter can be used for metal materials. Processing.

2.Laser power:

Choose the appropriate laser power according to the material to be processed. For some materials, such as acrylic, two-colour plates, etc., high-power laser tubes are not required, but for some other materials, such as stone, wood and other harder materials, Higher power is required. The excellent working performance will require a power laser tube.

- Working size:

Different applications require laser engraving machines with different working sizes. Generally, laser engraving machines of models 6040, 9060, 1290, 1390, 1490, 1610, 1612, 1812 can be used, for example, the working size of model 6040 is 600*400mm. Different Work scale and different prices. For example:

1) Rubber pad, rubber sheet, carton board: most laser engraving machines can be used to engrave on rubber sheets. The material does not require some special and fast machines, so it is recommended to use a laser engraving machine suitable for engraving rubber sheets, which is cheap, The investment is small, but the return is fast.

2) Bamboo, greeting cards, paper-cut gifts, wooden crafts, small ornaments, carved wooden boxes, wine boxes, bamboo tubes, tea tubes, crystal glass ornaments, acrylic crafts, etc., choose small machines, such as 9060 laser engraving machine (900X600mm), the price is extremely high Competitive, high precision, equipped with lifting platform and free replacement platform, can be widely used in various materials and profiles.

3) Acrylic plate: Most laser engraving machines can be used to cut acrylic plates, however, it is recommended to use a dedicated laser cutting machine. Because the laser cutting machine is optimized for laser cutting and has excellent cutting results. Usually: 60W laser engraver can Cut 8-10mm acrylic. 80w laser engraver can cut 8-15mm acrylic.

4) Clothing, leather: Choose a suitable laser engraving machine, which has a fast cutting speed and is equipped with a honeycomb cutting platform.

- Engraving speed;

On the premise of excellent engraving effect, pay attention to the working speed of the machine. Only when you produce more products in a short time, you can create higher profits.

- Engraving accuracy;

The biggest difference between a laser engraving machine and traditional engraving equipment with manual engraving is the engraving accuracy. For fine project drawings, the engraving accuracy requirements are relatively high.

- Machine quality;

1) Stepper motor: It will affect the engraving accuracy of the CNC laser engraving machine. There are different types of stepper motors available, including imported ones, household ones, high-quality ones and inferior ones, etc.

2) Laser lens: It affects the power of the laser engraving machine. It can be divided into imported lenses, domestic lenses, and domestic lenses can be divided into imported materials and domestic materials. The price difference is very large, and the work effect and service life are also in this way.

3) Laser tube: the heart of laser engraving machines. Most household laser engraving machines use domestic laser tubes.

4) Machine tools: When selecting, pay special attention to the quality of the machine, especially the thickness and strength of the structure.

Fiber laser cutter VS CO2 laser cutting machine

CO2 laser cutting machine is also a commonly used laser cutting machine for industrial purposes. But in actual use, there are big differences between a CO2 laser cutting machine and sheet metal laser cutting equipment. The differences mainly include the following aspects.

1. Laser generator The CO2 laser generator is a kind of gas molecular laser. It uses CO2 gas as the medium and transmits the laser beam through reflective lenses. However, fiber laser cutting machines work with diodes and fiber optic cables for beam transmission. The reflective lenses in the CO2 laser technology have to act at a certain distance. While the CNC fiber laser is not subject to such limitations.

2. Electro-optical conversion rate Fiber laser cutting system is the latest laser technology. Its solid-state laser generator is more efficient than a CO2 laser. The electro-optical conversion rate of a CO2 laser cutter is only 8%-10%. However, that rate of a fiber laser cutter can be as high as 30%. In other words, the overall energy consumption of a metal laser cutting machine is 3-5 times lower than that of a CO2 laser cutter. So the fiber laser machine is more energy-efficient.

3. Cutting ability Fiber laser has the property of short wavelength, thus improving the absorption of the beam by the cutting material. The fiber laser beam is more suitable for transmission in the fine and soft fiber. So it is more flexible and easier to maintain than the CO2 laser transmission with mirror reflection. A 3KW fiber laser cutting machine is equivalent to a 4-5KW CO2 laser cutting machine in terms of cutting capacity and speed. So the metal laser cutter can greatly reduce operating costs.

4. Maintenance cost As a CO2 laser cutter has a complex laser structure, its subsequent maintenance cost is relatively high. The CO2 laser cutting system requires regular cleaning, and the reflective lenses also require frequent cleaning and calibration. Due to the CO2 gas purity, you need to maintain the resonant cavity regularly. However, a CNC metal laser cutter doesn’t require the above maintenance, saving a large amount of cost.

5. Application Fiber laser cutting machine is mainly for metal cutting, such as mild or carbon steel, stainless steel, aluminum and its alloys, brass, copper, titanium, etc. While the Co2 CNC laser cutting machine is good at cutting non-metallic materials. It is now a solution to cut or engrave acrylic, wood, MDF, glass, etc.

Choose CNC Laser Cutter Service or Buy a Laser Machine?

CNC laser cutter service refers to the services that laser machining companies provide to cut and engrave products with various laser machines based on their customers’ requirements.

Choosing the laser cutting service or a laser machine has respective pros and cons, and suitable for different conditions.

Laser cutter service is very convenient for companies that occasionally require a small quantity of laser-cut products. It is not worthwhile for such companies to spend thousands of dollars to buy a laser cutter engraver for merely occasional use. So they can pay the laser cutting service providers the processing fees for laser cut and engraved products. But the laser cutter service quality is not consistent. So you need to spend some time and energy to find a qualified laser cutter service provider.

However, if your company lives on the sales of laser-cut or laser-engraved products, buying a laser machine is your best choice. The excellent flexibility, processing quality, and long service life of laser machine help improve your work efficiency and increase revenue.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.