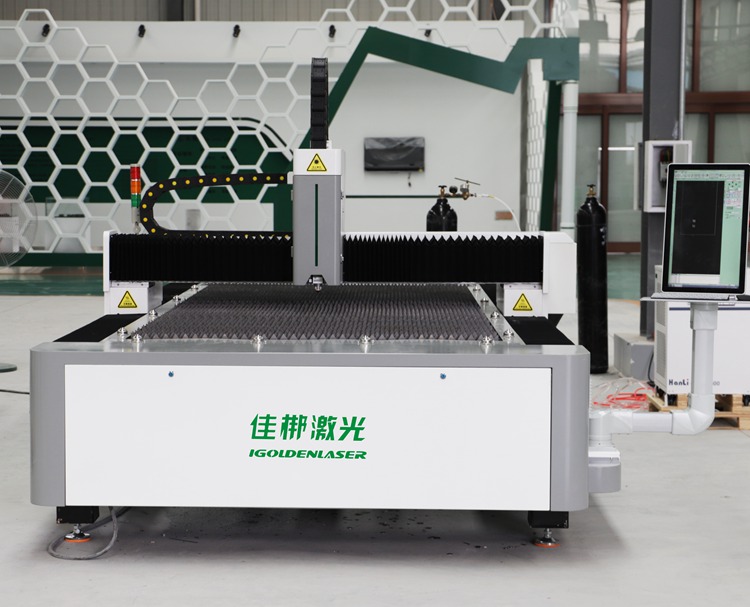

Fiber laser cutter is a CNC laser cutting system for metal, which is with high cutting quality, high cutting speed, high cutting precision and high cutting efficiency. It is suitable for most of of metal cutting and the fiber laser cutting machine is your good partner in metal processing. Equipped with different power (from 1,000W to 30,000w), it is used to cut metal materials with different thickness, such as stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron, etc.

Stainless Steel Laser Cutting Machine

This stainless steel cnc fiber laser cutting machine is specially designed for cutting sheet metal and many other materials. The machine has the advantages of low price, strong processing ability and good quality of accessories, and this carbon steel fiber laser cutting machine is widely used in the production of precision parts such as technology, digital products, electronic components, clocks, precision machinery, craft gifts and so on. Sheet metal cutting industry. This machine has been deeply loved by practitioners in the laser industry.

This stainless steel cnc fiber laser cutting machine is equipped with an advanced and high-quality transmission system, and it has silver square rails in Taiwan, which is more durable. And adopts high-quality helical rack and pinion with high precision. This machine adopts TBI ball screw, TBI ball screw, as the top brand of ball screw, is famous for its high precision and long service life. This enables the machine to run for a long time and avoids the machine crashing.

Our fiber laser cutter machine has three standard power: 500w, 1000w, 1500w or other custom made power, their price also increases with the increase of power. You can choose the most suitable machine according to your needs, which can reduce your machine cost. This machine is a professional sheet metal cutting laser machine. You can use it to process various metal plates.

Laser Cutting Machine for Aluminum

Laser cutting aluminum is a manufacturing process that uses a high-powered and tightly focused laser beam. This is to precisely cut aluminum sheets or plates to exactly match CAD-specified shapes or patterns. It is a critically important method for metal fabrication, offering major advantages over more traditional cutting techniques. Laser cutting aluminum is common in various industries, including aerospace, automotive, electronics, signage, and architectural applications. It offers a precise and efficient method for cutting aluminum with high quality and consistency.

The specific details of the laser cutting process vary according to the type and power of the laser machine used and the specific operational parameters optimized by the operator. In general, the laser cutting process involves the following steps:

- Prepare the material by cleaning the surface and ensuring it is securely positioned on the cutting table.

- Set up the cutting parameters such as laser power, CNC-controlled feed speed and path, assist-gas type and pressure, and nozzle position. This involves trial and iteration of settings.

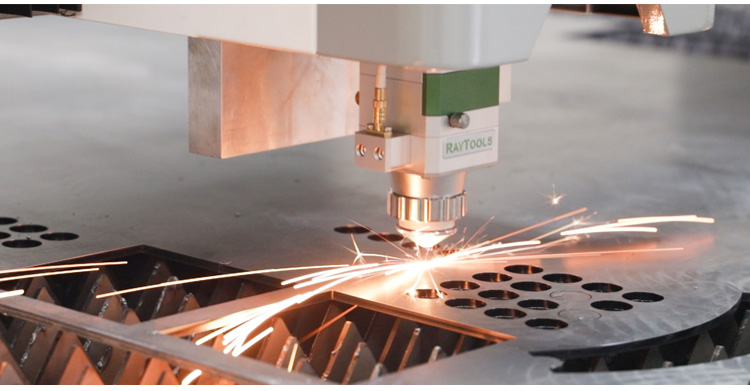

- Direct the focused laser beam onto the aluminum surface, rapidly heating and melting/vaporizing the material. Simultaneously, assist gas such as nitrogen is directed through a nozzle to blow away the molten metal and clear the kerf or cut path.

- The assist gas rapidly cools the newly cut region as the beam moves further along the cutting path.

Advantages of Laser Cutting Aluminum

High Precision

One of the most significant benefits of laser cutting aluminum is the high precision it offers. Whether you’re dealing with fiber lasers or CO2 lasers, the laser beam can be focused down to a fraction of a millimeter, allowing for intricate shapes and patterns to be cut with incredible accuracy.

Speed

Time is of the essence in any manufacturing process, and laser cutting aluminum is no different. With high power density and quick feed rates, the laser cutting process significantly reduces the time needed to cut through aluminum sheets or plates.

Versatility

The application range of laser cutting aluminum is broad. With adjustable settings and focus points, one can cut different thicknesses and types of aluminum alloys, making the method incredibly versatile.

Additional Advantages Laser Power: Adjustable, ensuring that you can cut through different thicknesses.

Cut Quality: Produces cleaner edges with little to no burr.

Wavelength: Allows for adjustment to suit material characteristics.

Automated Operation: Minimizes human error and streamlines the production process.

Carbon Steel Laser Cutting Machine

Can You Laser Cut Carbon Steel?

Yes, laser cutting is particularly effective on carbon steel due to its good absorption of laser energy. The process involves using a laser beam to melt, burn, or vaporize the material, resulting in a precise and clean cut.

Absorption Characteristics: Carbon steel exhibits good absorption of laser energy due to its primary component being carbon. The absorption of laser energy on carbon steel is converted into heat, contributing to a more efficient cutting process.

Cutting Speed: The cutting speed of carbon steel is typically relatively fast, attributed to the favorable cutting effect of laser on carbon steel. It enables swift penetration and completion of the cutting process.

Thermal Conductivity: Carbon steel has a relatively low thermal conductivity, meaning that laser energy is more easily concentrated and generates high temperatures in carbon steel. This is advantageous for achieving higher quality cutting.

Fiber laser cutting carbon steel is characterized by its relatively high absorption and conversion efficiency on carbon steel, thus enabling a more efficient and higher quality cutting process. This makes fiber laser cutting machines more widely used in carbon steel applications, including the fabrication of automotive components, structural steel, machinery parts, and more.

Advantages of Carbon Steel Cutting with Fiber Laser Cutting Machine

Applicability:

Laser cutting machines can be widely used for processing carbon steel materials. Problems that may occur in traditional carbon steel processing, such as scarring, cracking, delamination, white spots, impurities, and looseness, are improved in laser cutting.

Efficient Processing:

Due to the presence of carbon in carbon steel, which has a weak reflection to light, it readily absorbs the laser beam. This high energy conversion efficiency on carbon steel facilitates efficient cutting.

Optical Characteristics Advantage:

Under laser beam, carbon steel undergoes a high-temperature reaction. With the assistance of auxiliary gases, reactions occur with elements such as silicon, manganese, sulfur, and phosphorus contained in carbon steel, leading to oxidation, melting, and vaporization, allowing rapid penetration of carbon steel.

Excellent Cutting Effect:

Laser cutting carbon steel can realize high-quality processing effect. The cutting surface is flat, smooth and beautiful, which not only improves the appearance quality of the workpiece, but also facilitates subsequent processing procedures.

Cost Savings:

Laser cutting machines are convenient and safe to use, contributing to cost savings in carbon steel processing. The efficient cutting speed and quality reduce production costs and increase productivity.

Cutting Thickness:

When cutting carbon steel, laser cutting machines can handle relatively thick materials, with a maximum thickness of up to 50mm of carbon steel. This convenience is beneficial for processing thicker carbon steel workpieces.

Application Industries:

Stainless steel cnc fiber laser cutting machine are widely used in manufacture billboard, advertising, signs, signage, metal letters, LED letters, kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts, nameplates, refrigeration machinery, agricultural machinery, food machinery, kitchen stainless steel countertops, aerospace, railroad locomotive, auto parts manufacturing, car body processing, medical equipment, smart home, home appliances, kitchen equipment, fitness equipment, machinery manufacturing, sheet metal processing. etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.