Laser Knowledge

1390 Small Acrylic Laser Cutting and Engraving Machine

The Co2 laser cutting machine is mainly for non-metal cutting, engraving, and marking, it also be named as a CNC laser engraver machine, CNC laser cutter machine, etc.

1390 is an affordable large-scale CO2 laser engraving machine that increases productivity both in home and industrial use. The 1390 laser machine can not only engrave, but also has the function of cutting. You can use it to cut or engrave most of the non-metallic materials, especially acrylic cutting under 20mm, wood cutting below 15mm, cloth and leather cutting.

This machine is an economical CO2 laser engraving machine and cutting machine. Equipped with a special machine protection cover, which not only guarantees the personal safety of the operator, and it also makes the entire processing production more environmentally friendly. Besides that the protective cover can be removed, so it can meet the different processing needs of users.

Carbon dioxide laser is a gas molecular laser, the working substance is CO2 gas, auxiliary gases are nitrogen helium, xenon and hydrogen, etc., because the energy conversion efficiency of this laser is as high as 25%, it is often a high-power output laser, carbon dioxide laser wavelength 10.6 microns, is impossible to see infrared light, good stability, widely used.

Using the most advanced DSP control technology in the world, the first industry-leading continuous and fast curve cutting function and the shortest machining path optimization function, greatly improving work efficiency. Automatic light attenuation compensation for the whole process of engraving, to ensure that different areas of cutting to maintain consistency, fast cutting control software design and high-speed motion buffer function, can improve production efficiency.

Laser Cutting and Engraving Machine Advanced Performance

- High processing efficiency, 10 to 15 times that of manual engraving; high precision, low cost, and good printing effect;

- The optimized design of the mechanical structure and the smallest overall size of the whole machine not only saves your precious space, but also the structure should not be deformed and the cutting precision is high;

- Taiwan square linear guide, long life;

- The use of patented technology makes the engraving effect of the rubber plate better, and it is not easy to burn;

- Genuine laser engraving software, powerful; engraving and cutting can be carried out at the same time.

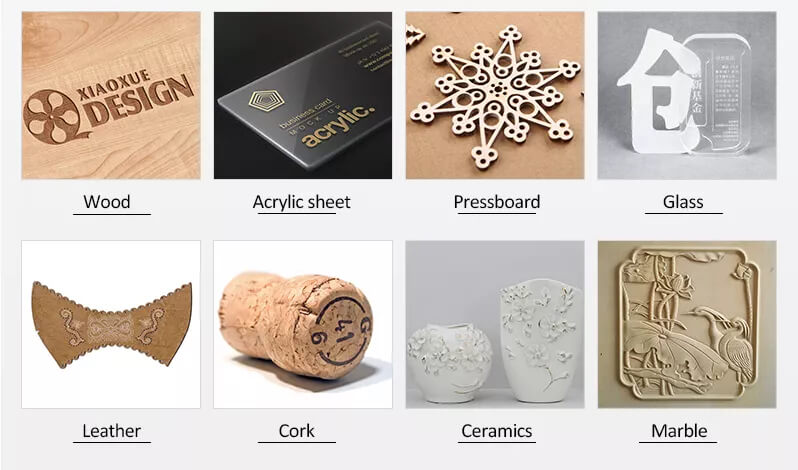

Applicable materials

Wood, bamboo, jade, marble, organic glass, crystal, plastic, garments, paper, leather, rubber, ceramic, glass and other nonmetal materials.

Applicable industries

Advertisement, arts and crafts, leather, toys, garments, model, building upholster, computerized embroidery and clipping, packaging and paper industry.

Key Features1390 Laser Cutting and Engraving Machine

- Working Area: The 1390 model typically refers to the dimensions of the machine’s working area, which is 1300mm x 900mm (or approximately 51 inches x 35 inches). This indicates the maximum size of the material that can be placed and processed within the machine.

- Laser Source: The machine is equipped with a laser source, which emits a high-powered laser beam. The laser source can be based on different technologies, such as CO2 or fiber, each with its own advantages and suitability for specific materials.

- Cutting and Engraving Capability: The 1390 laser machine can perform both cutting and engraving operations. It utilizes the laser beam to cut through or vaporize the material, creating precise and clean cuts. It can also engrave intricate designs, patterns, or text onto the surface of the material, adding decorative or informational elements.

- Laser Power: The laser power of the 1390 model can vary depending on the specific machine and manufacturer. The power typically ranges from 60 watts to 150 watts or more. Higher laser power allows for faster cutting speeds and the ability to process thicker or denser materials.

- Control System: The machine is controlled by a dedicated control system that interfaces with the operator. It allows for the import of design files and provides tools for setting cutting parameters, controlling the laser power, adjusting cutting speed, and managing other operations.

- Software Compatibility: The 1390 laser cutting and engraving machine is typically compatible with various design software and file formats. Common formats include DXF, AI, PLT, and BMP. This compatibility enables users to import their designs and easily convert them into cutting or engraving paths.

- Safety Features: Laser machines incorporate safety features to protect operators and prevent accidents. These may include safety enclosures, emergency stop buttons, and interlocks that ensure the laser beam is only active when the machine is securely closed.

When considering a 1390 laser cutting and engraving machine, it’s important to assess your specific requirements, including the materials you plan to work with, desired cutting and engraving capabilities, laser power needs, and budget considerations.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.