Buyer Guide

Automatic Fiber Laser Metal Tube Cutting Machine

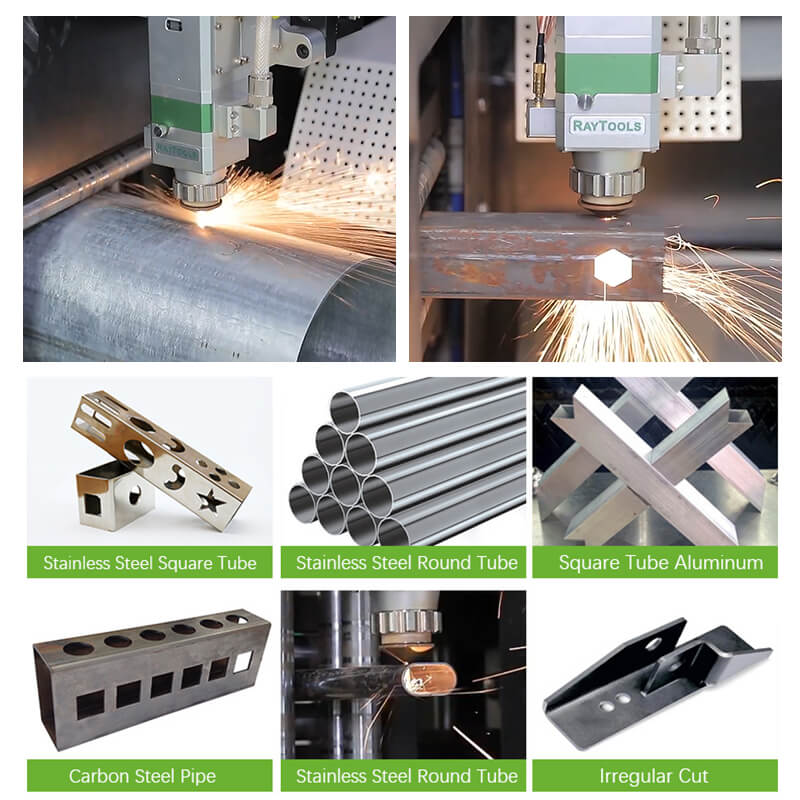

A laser metal tube cutting machine is an automatic CNC pipe cutter that uses fiber laser beam to cut round tubes, square tubes, rectangular tubes, oval pipes, elliptical tubes, hexagonal tubes, triangular tubes and some custom special shape pipes in a variety of metals, including stainless steel, carbon steel, mild steel, tool steel, alloy, aluminum, brass, copper, bronze and titanium. It is a dieless cutting system to cut any types of designs on metal pipes in any angle and direction. Compared with flame cutting, plasma cutting, wire cutting, and water jet cutting, the fiber laser tube cutter is easy to use with a high degree of automation, low cost, high speed and high quality, and the laser-cut metal precision is much higher without grinding.

Laser Metal Tube Cutting Machine

An automatic laser tube cutter will replace mechanical drilling, milling, sawing, punching or cleaning of burrs and other processing procedures that require different metal pipe cutters and hard tools, and realize the cutting, chamfering, and cutting of complex pipe structures. The processing of slots or holes, notches, and other possible size and shape features. It is widely used in metal fabrication, kitchenware, lamps, automobiles, medical equipment, hardware, fitness equipment, and other industries.

The pipe cutting machine adopts a gantry bridge structure, which ensures stable operation and prevents deformation. It is equipped with a gantry protective cover to prevent laser burns and smoke damage, ensuring the safety of operators and protecting the environment.

Optional laser power 1000W-6000W; Optional countertop 6016/6024/6036; 3 meter tube and 6 meter tube are standard.

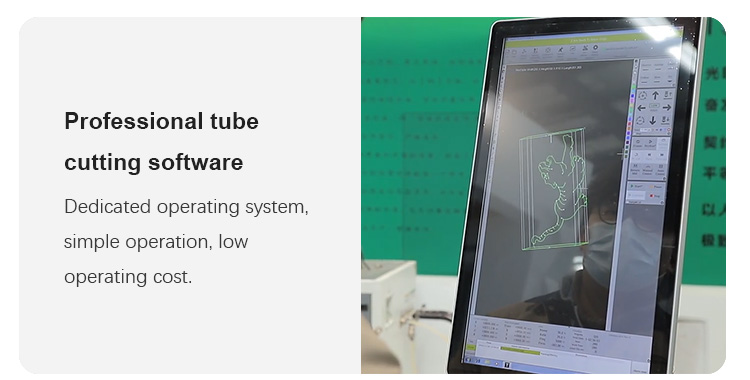

Laser tube cutter uses computer-aided design software for graphic design, and imports the operating system to automate cutting, maximizing the speed of manufacturing projects. Usually, a database is included in the operating system, and the key information includes the material type, thickness, and geometry of the tube. The main working principle of the automatic tube cutting machine is to use the thermal energy generated by the laser beam from the laser to cooperate with the motion mechanical system to cut the pipe. The cut pipe is controlled by the intelligent system, which can achieve the purpose of high-quality university production.

Automatic Feeding System

The machine has increased the height of the material loading on the bed, making it more ergonomic and facilitating the loading process. The front and rear chuck clamping design allows for easy installation, minimal effort, and no consumable wear, ensuring smooth feeding and cutting precision.Realize the intelligent material separation, feeding and seamless docking with the fiber laser cutting machine after the whole bundles of tubes are placed in the feeding device, and ensure that only one tube is delivered to the conveying arm each time.

Metal Tube Laser Cutting Machine Features

- The fiber laser tube cutter can complete a variety of cutting shapes tubes, the tube surface arbitrarily complex curve graphics processing, graphics difficulty without restrictions. After cutting the tube section does not require secondary processing, it can be welded directly, greatly reducing the production period, creating enormous value for the enterprise.

- It can cut lines and holes with different diameters from different directions on the tubes & pipes and cut column and crossed lines at the end of branch pipe to meet centrifugal and non-centrifugal vertical intersection condition for branch and main pipe axis.

- It can cut inclined with the main circular pipe.

- It can cut branch pipe intersected with the main circular pipe.

- It can realize angle groove face, square hole, waist-shaped holes cutting.

- It adopts very thin laser beam which can be used on small part cutting and complicated patterns and reach to a polished effect.

- Two rotary tables use double driver synchronous drive, metal tubes are not easily destroyed when processing, with high precision and high processing efficiency.

Advantages of CNC Laser Tube Cutting Machine with Fiber Laser Source

Automatic double pneumatic chucks, stable and efficient The chuck device is controlled by one key and can realize automatic centering, reducing the waiting time for loading and unloading. The constant and large clamping force guarantees no loose or sliding of heavy pipes, thus ensuring the cutting precision. It is also equipped with special support frame to avoid pipe sagging deformation, and to improve the cutting accuracy while extending the life of the chuck.

The real difference of the laser tube cutting machine is the cutting accuracy. It adopts chuck and push-type cutting methods, which has high centering accuracy and processing accuracy; due to the improvement of modern laser cutting machines, it involves the industrial manufacturing of small diameter pipes. The application has been greatly accelerated. The automatic pipe cutter can make corresponding adjustments according to these deformations to ensure the accuracy of pipe cutting, which cannot be achieved by many traditional processes.

Laser tube cutter can realize mass production, and all operations can be unified into the same unit as a continuous operation process, which greatly reduces the logistics time. The standard pipe length is 6 meters, and the traditional processing method requires very heavy clamping. Laser processing can easily complete the clamping and positioning of several meters of pipe, which makes batch processing possible.

Metal Tube Laser Cutting Machine Applications

Metal tube & pipe diameter: ≤200mm.

Metal tube & pipe cutting thickness: ≤8mm (mild steel).

Metal tube & pipe types: round, square, triangle, rectangle, oval, circular tubes and more other special tubes.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.