Buyer Guide

Stainless Steel Welding by Fiber Laser Welding Machine

Stainless Steel Laser Welding Machine

Fiber laser welding machines are widely used for stainless steel welding due to their high precision, speed, and efficiency. Stainless steel is a common material in industries such as automotive, aerospace, medical, and manufacturing.

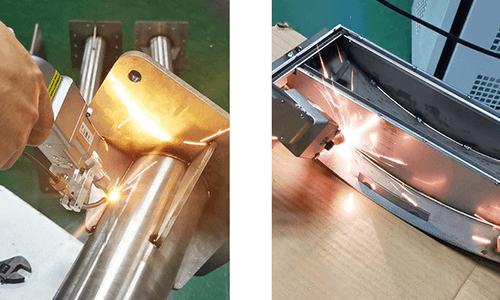

This handheld fiber laser welding machine is one of the most popular welding machines in the current world. It adopts a handheld welding head which is very convenient to operate. It has high welding efficiency and small thermal impact. This machine can weld various metals including thin metal plates.

Stainless Steel Fiber Laser Welding Machine Features

- Fiber Laser Technology: Fiber laser welding machines utilize a high-powered fiber laser as the energy source. Fiber lasers provide a concentrated and intense laser beam that can be precisely controlled, allowing for accurate and controlled heat input during the welding process.

- High Precision: Fiber laser welding offers excellent precision, enabling precise control over the weld size, depth, and position. This precision is particularly important for stainless steel welding, as it allows for tight weld seams and accurate weld profiles.

- Deep Penetration: Fiber lasers can achieve deep penetration when welding stainless steel. This deep penetration capability allows for efficient and effective welding, resulting in strong and reliable weld joints.

- Welding Speed: Fiber laser welding machines can operate at high welding speeds, making them suitable for high-volume production. The fast welding speeds, combined with the deep penetration, contribute to increased productivity and reduced manufacturing costs.

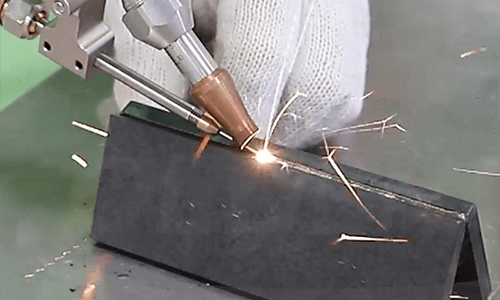

- Weld Quality and Aesthetics: Fiber laser welding produces welds with minimal distortion and excellent aesthetic appearance. The precise heat input and control provided by fiber lasers result in clean and visually appealing welds, which are particularly desirable for applications where the appearance of the weld joint is important.

- Weld Strength: Stainless steel welding using fiber laser technology can achieve high weld strength. The deep penetration and controlled heat input contribute to strong and durable weld joints, ensuring the integrity and reliability of the welded stainless steel components.

- Material Compatibility: Fiber laser welding machines can be used to weld various grades of stainless steel, including austenitic, ferritic, and martensitic stainless steels. This makes them suitable for a wide range of applications that require stainless steel welding.

The laser hand-held laser welding machine adopts the latest generation of fiber lasers and is equipped with a self-developed wobble welding head to fill the gap of hand-held welding in the laser equipment industry. It has the advantages of simple operation, beautiful weld seam, fast welding speed and no consumables.

Stainless Steel Application

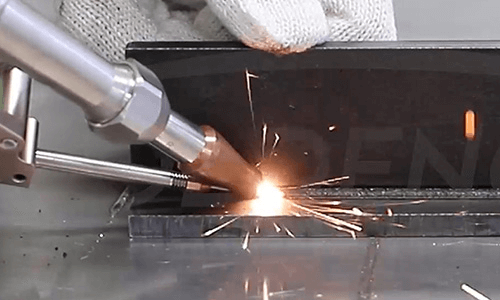

This laser welding machine can be used for welding Stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials, such as: copper – brass, titanium – molybdenum, titanium – gold, nickel – copper and so on.

Fiber laser welding machine is widely used in complicated and irregular welding procedures of cupboard, Kitchenware, elevators, shelves, ovens, ss doors and window guardrails, distribution boxes, and other metal household appliances industries.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.