Uncategorized

1000w 1500w 2kw 3000 Watt Fiber Laser Cutting Machine

Laser cutting machine for metal plate are widely used in various industries, including automotive, aerospace, metal processing and fabrication. They can cut through several types of metals, such as steel, aluminum, brass, and copper. It is high cutting speed, minimal heat-affected zone, intricate designs, and the ability to cut complex shapes accurately.

1000w Fiber Laser Cutting Machine

A 1000W fiber laser cutting machine refers to a fiber laser cutting machine equipped with a laser source that has a power output of 1000 watts. The power output of the laser source determines the cutting capability and speed of the machine. 1000W fiber laser cutting machine is capable of cutting through various materials with thicknesses ranging from thin sheets to moderately thick plates. The specific cutting capacity depends on the material being cut, but generally, it can handle metals such as stainless steel, carbon steel, aluminum, brass, copper, and other alloys.

Fiber Laser Cutting Machine Advantages:

- Professional laser optical system and imported lenses, stable and reliable;

- Efficient and stable programming and control system, easy to learn and humanized, compatible with a variety of CAD drawing formats, intelligent layout to save costs, automatic cutting paths, matching and saving processing time;

- The CNC metal fiber laser cutting machine has low energy consumption and low use cost; the equipment has high stability, simple and convenient maintenance, and low maintenance cost; no mold is required, flexible processing, and can meet the processing requirements of various special-shaped workpieces;

- High cutting efficiency, high cutting quality, no noise; high speed, high efficiency, cutting thin plates up to 30 meters per minute; cutting edge quality, small deformation, smooth and beautiful appearance;

- Imported high-precision servo motors, guide rails, and German-made gear racks, while ensuring processing efficiency and processing accuracy, greatly improve the stability and reliability of equipment operation.

1000w 1500w 2kw 3000 Watt Fiber Laser Cutting Machine Cutting parameters

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Carbon Steel O₂ | 1 | 7.0-9.0 | 9.0-12.0 | 10.0-12.0 | 10.0-12.0 | 8.0-12.0 | 8.0-12.0 | 8.0-12.0 | 8.0-12.0 | 1 |

| 2 | 3.0-3.7 | 4.8-5.5 | 5.0-6.0 | 5.5-7.0 | 6.0-7.5 | 6.0-7.5 | 6.0-7.5 | 6.0-7.5 | 2 | |

| 3 | 2.0-2.5 | 3.0-3.8 | 3.8-4.2 | 4.0-4.6 | 4.3-5.2 | 3.5-5.0 | 3.5-5.0 | 3.8-5.0 | 3 | |

| 4 | 1.4-1.7 | 1.8-2.2 | 2.5-3.0 | 2.5-3.2 | 2.8-3.7 | 3.0-4.2 | 3.3-4.5 | 3.5-4.5 | 4 | |

| 5 | 1.0-1.5 | 1.5-1.8 | 1.5-2.2 | 1.8-2.5 | 2.2-3.1 | 2.5-3.6 | 2.8-3.6 | 3.0-3.8 | 5 | |

| 6 | 0.6-0.8 | 1.2-1.5 | 1.2-1.8 | 1.6-2.2 | 1.8-2.6 | 2.4-3.0 | 2.5-3.2 | 2.6-3.2 | 6 | |

| 8 | 0.9-1.1 | 1.0-1.2 | 1.1-1.5 | 1.2-1.3 | 1.8-2.4 | 1.9-2.5 | 2.0-2.6 | 8 | ||

| 10 | 0.6-0.9 | 1.0-1.2 | 1.1-1.2 | 1.2-1.8 | 1.7-2.1 | 1.8-2.2 | 10 | |||

| 12 | 0.9-1.0 | 0.9-1.1 | 1.0-1.5 | 1.0-1.5 | 1.5-2.0 | 12 | ||||

| 16 | 0.65-0.75 | 0.7-0.85 | 0.7-0.85 | 0.7-0.9 | 16 | |||||

| 20 | 0.6-0.75 | 0.6-0.75 | 0.6-0.8 | 20 | ||||||

| 22 | 0.4-0.6 | 0.4-0.6 | 22 | |||||||

| 25 | 0.4-0.6 | 25 | ||||||||

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Stainless steel N₂ | 1 | 8.0-10.0 | 11.5-13.5 | 14.0-16.0 | 16.0-18.0 | 20.0-28.0 | 20.0-28.0 | 35.0-42.0 | 50.0-70.0 | 1 |

| 2 | 2.0-2.5 | 3.2-3.8 | 4.0-5.0 | 5.0-7.0 | 9.0-13.0 | 9.0-13.0 | 15.0-23.0 | 30.0-40.0 | 2 | |

| 3 | 1.0-1.5 | 2.0-3.0 | 3.2-4.5 | 4.0-6.5 | 4.0-6.5 | 7.0-11.0 | 17.0-22.0 | 3 | ||

| 4 | 1.2-1.6 | 2.0-2.8 | 3.0-4.5 | 3.0-4.5 | 4.0-6.0 | 9.0-14.0 | 4 | |||

| 5 | 0.7-1.0 | 1.2-2.0 | 1.4-2.5 | 1.4-2.5 | 2.5-4.0 | 7.0-12.0 | 5 | |||

| 6 | 0.7-1.0 | 0.9-1.8 | 0.9-1.8 | 2.0-3.2 | 5.0-8.0 | 6 | ||||

| 8 | 1.2-1.8 | 3.8-5.0 | 8 | |||||||

| 10 | 0.7-0.9 | 1.6-2.5 | 10 | |||||||

| 12 | 1.1-1.8 | 12 | ||||||||

| 16 | 0.7-1.2 | 16 | ||||||||

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Aluminum alloy N₂ | 1 | 8.0-10.0 | 4.5-6.0 | 8.0-10.0 | 8.0-10.0 | 10.0-15.0 | 28.0-35.0 | 30.0-39.0 | 50.0-60.0 | 1 |

| 2 | 2.0-2.5 | 1.5-2.5 | 3.8-4.5 | 3.8-4.5 | 5.0-6.0 | 12.0-16.0 | 12.0-22.0 | 22.0-35.0 | 2 | |

| 3 | 1.4-2.0 | 1.4-2.0 | 2.5-3.5 | 6.5-8.0 | 6.0-13.0 | 12.0-18.0 | 3 | |||

| 4 | 1.4-2.0 | 3.5-5.0 | 3.8-5.5 | 9.0-12.0 | 4 | |||||

| 5 | 0.8-1.0 | 2.5-3.5 | 2.8-4.0 | 4.5-8.0 | 5 | |||||

| 6 | 1.8-3.0 | 2.5-3.5 | 3.8-6.0 | 6 | ||||||

| 8 | 0.9-1.3 | 0.8-1.6 | 1.8-3.0 | 8 | ||||||

| 10 | 0.5-1.0 | 1.0-2.1 | 10 | |||||||

| 12 | 0.8-1.5 | 12 | ||||||||

| 16 | 16 | |||||||||

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Brass N₂ | 1 | 2.0-3.5 | 4.5-6.0 | 4.5-8.0 | 8.0-12.0 | 10.0-16.0 | 20.0-32.0 | 23.0-30.0 | 40.0-55.0 | 1 |

| 2 | 0.7-1.0 | 1.0-2.0 | 2.5-3.5 | 3.5-5.0 | 6.0-8.0 | 9.0-11.0 | 9.0-13.0 | 30.0-35.0 | 2 | |

| 3 | 2.0-3.0 | 2.5-4.0 | 5.0-6.5 | 5.0-6.5 | 11.0-18.0 | 3 | ||||

| 4 | 1.6-2.2 | 3.0-4.5 | 3.0-5.2 | 7.5-10.0 | 4 | |||||

| 5 | 0.7-1.2 | 1.5-2.0 | 1.8-3.0 | 5.5-7.0 | 5 | |||||

| 6 | 1.0-1.6 | 1.3-2.0 | 3.2-4.5 | 6 | ||||||

| 8 | 0.6-0.8 | 1.5-2.2 | 8 | |||||||

| 10 | 0.7-1.2 | 10 | ||||||||

The laser sheet cutting machine are high precision, speed, and ability to cut through a wide range of metal plate materials, including steel, stainless steel, aluminum, copper, brass, and more. They offer superior cutting quality with minimal heat-affected zones, resulting in clean and accurate cuts. Additionally, fiber laser cutters are more energy-efficient and require lower maintenance compared to traditional CO2 laser cutters.

- High rigidity machine bed, exclusively treated with high-temperature CNC electric furnace annealing process, ensuring Long-term stability of machine accuracy.

- Imported original packaged fber laser, with good beam quality and stable performance, no reflective mirrors, no need for optical adjustment, virtually maintenance-free, with a service Life of over 100,000 hours.

- High electro-optical conversion efficiency of the fiber Laser, reaching an eficiency of 30%, which significantly saves power consumption during operation and results in extremely low operating costs.

- Fast cutting speed and Low operating costs, providing a quick return on investment.

Metal Laser Cutter Machine

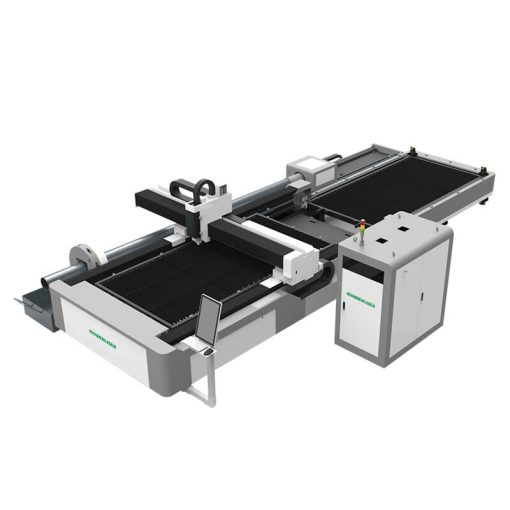

Metal Laser Cutting Machine iGR-F

This sheet metal fiber laser cutter is an ideal entry level laser cutting machine for you to process the metal materials. With easy operation and simple maintenance, this machine can provide users powerful cutting ability and efficiency.In the cutting process of fiber laser for general metal materials, due to the fast cutting speed, the thermal deformation of the parts is small, and the dimensional accuracy of the cut parts mainly depends on the mechanical accuracy and control accuracy of the worktable of the laser cutting machine. In the fibre laser cutting process, the high-precision cutting device and control technology are used, and the dimensional accuracy can reach the highest level.

Application Industries&Materials:

- Application industries: metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agricultural and forestry machinery, elevator manufacturing, special automobiles, household appliances manufacturing, tool processing, IT manufacturing, petroleum machinery manufacturing, food machinery, Diamond tool welding, gear welding, metal material surface treatment, decorative advertising, laser external processing services and other machinery manufacturing and processing industries.

- Applicable materials: professionally used to cut a variety of medium and thin metal plates, high-quality cutting carbon steel plates, and Especially for carbon steel, stainless steel, galvanized steel, alloy, titanium, aluminum, brass, copper, etc

Metal Laser Cutting Machine Features

1. Intelligent automatic focusing laser head Automatic focusing mode of the laser head reduces human interference with a focusing speed of 10m/min and repeated positioning accuracy of 50um.

2. Aviation aluminum beam Aviation aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

3. High quality thick wall carbon steel plate welding bed High strength machine bed is more stable and durable. After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

4. Integrated large volume dust removal system The dust removal system can remove all the smoke generated from the cutting process with large air volume. This helps protect the operator’s health and the working environment.

5. Automatic lubrication system Automatic lubrication method saves more human labor, reduces maintenance time, and greatly improves work efficiency.

How to choose the suitable fiber laser cutting machine?

Here i will be able to introduce the way to choose a fiber laser cutting machine correctly, which may be considered from the subsequent aspects.

1. the wants for the materials and business processed by the enterprise

First of all, we should always consider the scope of our business, the thickness of the cutting material, which material must be cut, then determine the dimensions of the equipment that must be purchased and therefore the size of the worktable. at the present , the facility of the laser cutting machine on the market is between 500W-6000W, and therefore the size of the manufacturers of the worktable are often consistent with the customer. Demand to customize.

2. The initial choice of the manufacturer

After we confirm the demand, we will attend the market to know or to ascertain the performance and basic parameters of the machine. Select variety of strong and price preferential manufacturers for early communication and sample, and later we will perform field inspection, the worth of the machine, machine training, payment methods, after-sales service then on more detailed discussion.

3. the dimensions of laser power

When we choose the performance of laser cutting machine, we should always give full consideration to our surroundings . the dimensions of the laser power is extremely important, for instance , we frequently cut the metal sheet below 6mm, then we elect 100W-2000W laser cutting machine to satisfy the demand of production. If we cut quite 6mm material, we’d like to think about a bigger power machine, which is extremely helpful to the value control of enterprises.

4. The core a part of the laser cutting machine

We also got to pay great attention when choosing some important parts of laser cutting machines. especially , the laser generator, laser cutting head, servo motor, guide rail, cistern , etc., we’ve to differentiate whether it’s made in China or imported. of these components directly affect the cutting speed and accuracy of laser cutting machine.

5. Equipment quality and use stability also are important indicators.

Now the research and development cycle of the merchandise is brief , the renewal and replacement are becoming faster and faster. the variability of products, the sample trial production and therefore the production are more. the way to guarantee the customer order, maintain the reputation of the enterprise, and enhance the competitiveness of the enterprise is additionally the arduous task for every operator. Therefore, the choice and buy of stable processing equipment is that the premise and basis, as far as possible to settle on the brand with high market share, perfect after-sales service system, many after-sales service outlets and long market inspection. we will not covet cheap products and buy poor quality products without after-sales service, which can have an enormous impact on the assembly of enterprises.

6. After-sale service

The after-sales service of every manufacturer varies greatly, and therefore the warranty time is uneven. In after-sales service, we should always not only provide customers with effective daily maintenance programs, but even have knowledgeable training system to assist customers start as soon as possible.

No matter how good a laser cutting machine is doing, the user will encounter a spread of problems within the process of using it. When it meets the matter that the customer can’t solve, it’s vital for the manufacturer to supply a timely solution. it’s also a crucial consideration once we prefer to choose the laser cutting machine.

Product Recommendation

Laser Cutting Machine

Metal Sheet and Pipe Laser Cutting Machine with Exchange Worktable

Laser Cutting Machine

Laser Cutting Machine

Laser Cutting Machine

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.