No products in the cart.

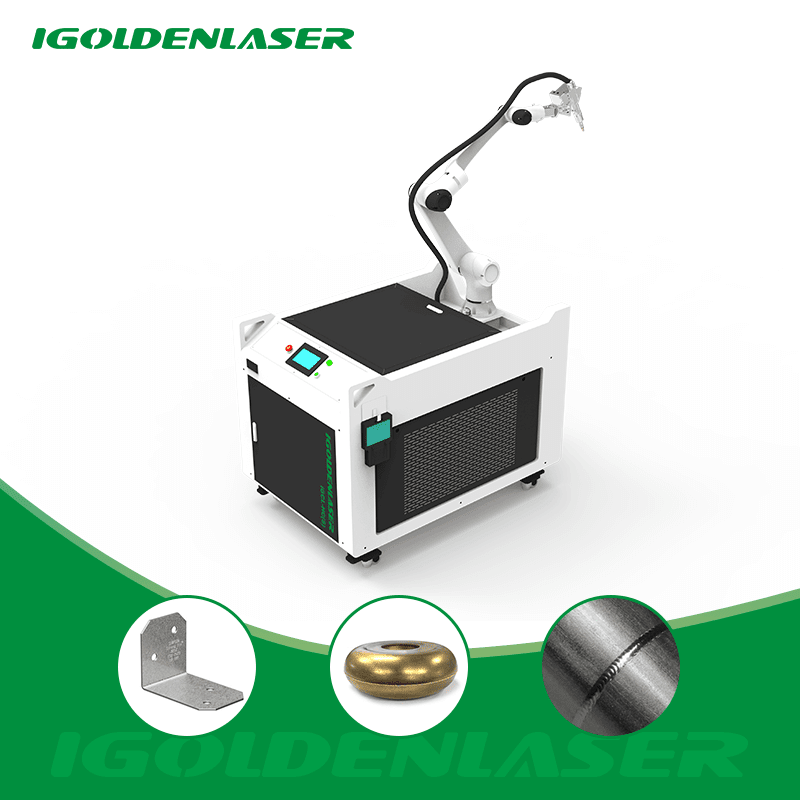

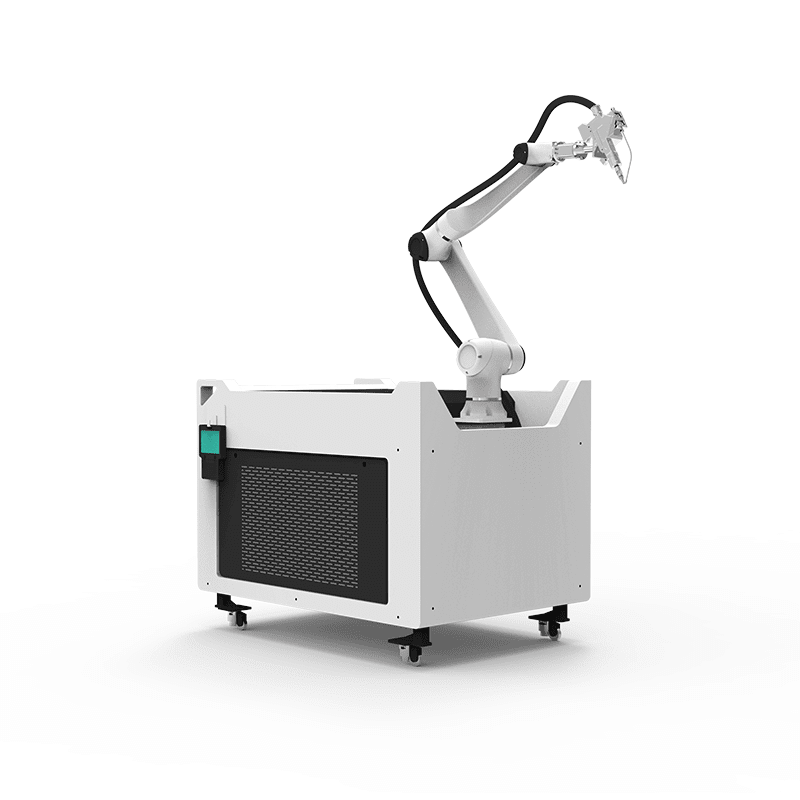

iGWL-RW(C)

Laser Welding Machine Collaborative Robot

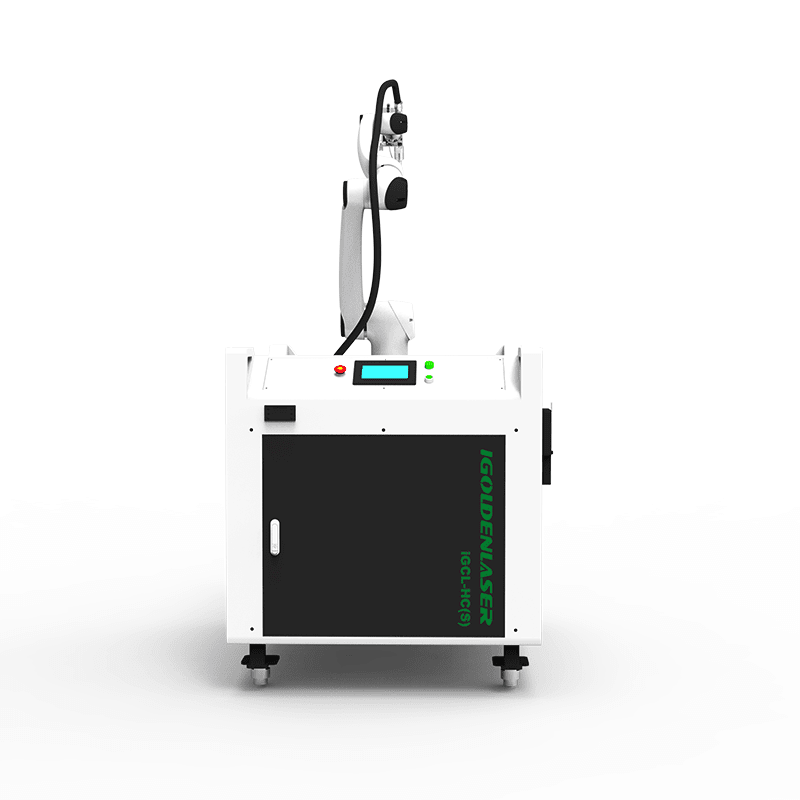

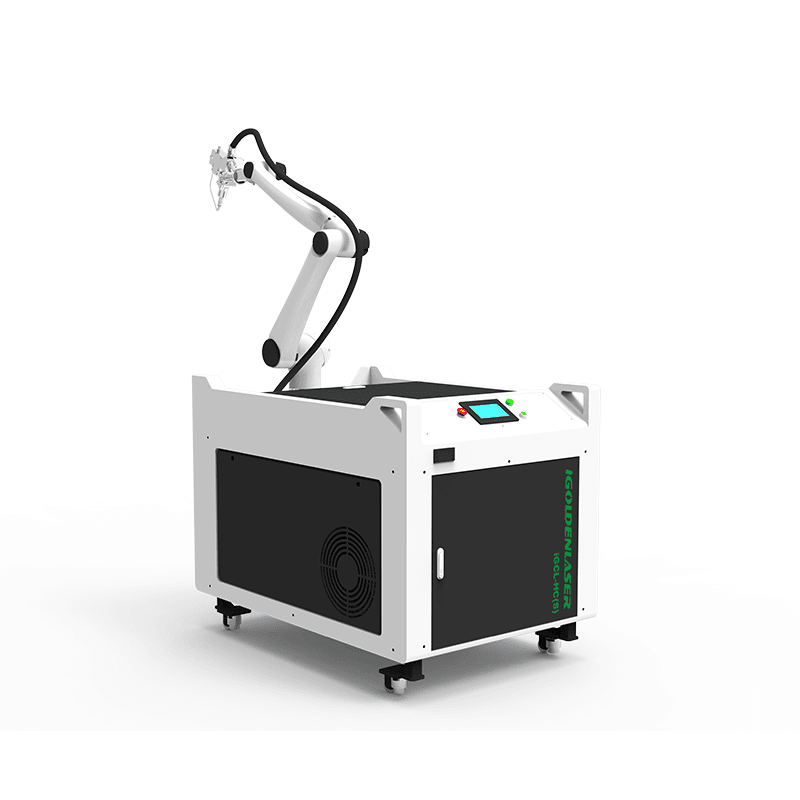

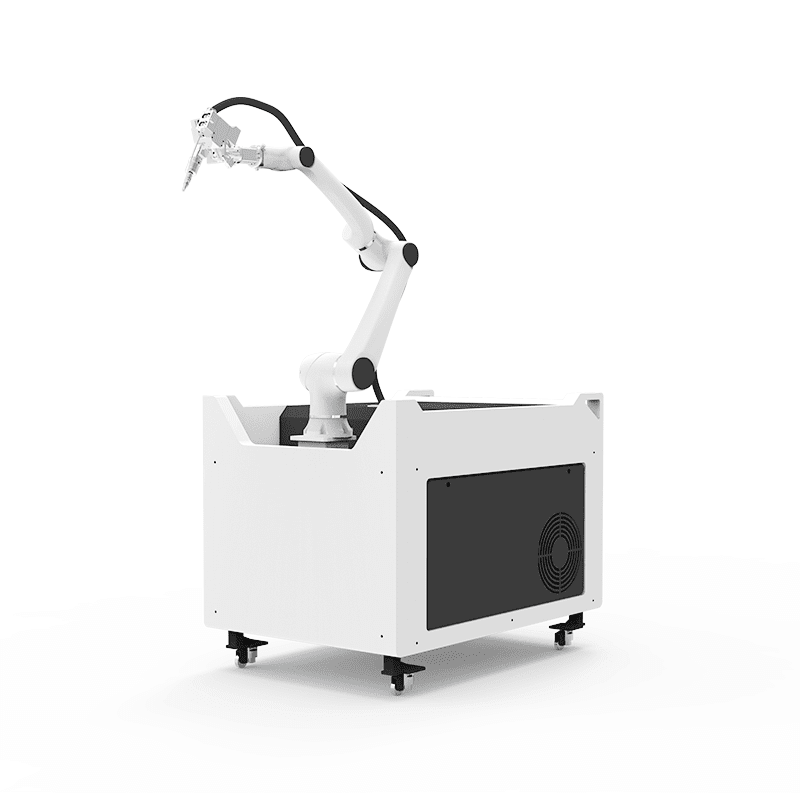

Automatic robotic laser welding machine consists of fiber laser, robot control system, positioning sensor, laser welding head and cooling system. It has the excellent welding speeds, aesthetic appearance and flexible movement of 6-axis robot arm.

The six axis configuration (rotation, lower arm, upper arm, wrist rotation, wrist swing, and wrist rotation) enables the end effector to orient the laser head in almost any direction — ideal for complex workpieces and 3D assemblies.

Collaborative robots can effectively cope with laser welding operations, helping to achieve flexible, efficient and free welding processes. Welding stability and consistency are higher, and product quality is easier to control.

- High precision: automatic fiber laser welding robot can achieve a high level of precision, resulting in accurate welds and a high-quality finished product.

- Flexibility for 3D weld paths and difficult-to-reach joints

- Faster welding speed: Since the laser beam is highly concentrated, it allows for faster and more efficient welding compared to traditional welding methods.

- Versatility & flexibility: Automatic robot laser welding machines are highly flexible and can handle a wide range of materials and thicknesses, including aluminum, stainless steel, and even plastics.

- Automated programming: Programming of the robotic laser welding machine can be automated, which means that it can be programmed to perform multiple welding tasks.

- Large work envelope: These machines have a large work envelope which allows them to handle large components and perform complex welding tasks.

Optional laser power 1500W-3000W; support customization.