Buyer Guide

Why We Choose Metal Laser Welding Machine

In recent years, the development of the manufacturing industry has been very rapid, and the demand for metal processing has also increased. Welding is one of the important processes in metal processing, and traditional welding methods can no longer meet the production needs. Under this premise, handheld laser welding machine were born, and once launched, they were widely praised and quickly replaced the traditional welding thin plate welding market. Handheld laser welding machine are widely used in fields such as sheet metal, chassis, water tanks, distribution boxes, cabinets, kitchens, and stainless steel door and window guardrails.

The development of the new era has promoted an increase in demand, requiring new processes and tools to meet these requirements. As a new process and tool in the welding field, handheld laser welding machine have a promising future and will gradually replace argon arc welding.

Laser welding is a fast process compared to traditional welding methods. The focused and intense laser beam enables rapid heating and cooling of the material, leading to efficient and quick welds. This can increase overall productivity in manufacturing.

Metal Laser Welding Machine

A metal laser welding machine, also known as a laser welder or laser welding system, is a type of equipment used for joining metal components together using laser technology. It utilizes a high-energy laser beam to melt and fuse the metal parts, creating a strong and precise weld.

Why We Choose Metal Laser Welding Machine

1.The handheld laser welding machine is easy to operate and can be welded in two hours, with low labor costs.

2.It is a continuous welding machine with dense beam energy, efficient and high-speed welding, small welding points, small heat affected areas, smooth and beautiful welds, and reduced subsequent polishing processes.

3.It can weld common metal materials such as stainless steel plate, iron plate, galvanized plate, aluminum plate, etc.

4.The handheld laser welding machine does not require a dedicated welding workbench, and the equipment occupies small space. It is flexible in processing and is equipped with several meters of fiber optic extension cables, which can be moved for long-distance operations without being limited by environmental space.

5.The laser is equipped with water cooling equipment to ensure continuous and high-intensity operation.

6.The handheld laser welding machine can not only perform welding operations, but also repair molds and perform simple cutting operations by replacing cutting nozzles. The laser has a lifespan of up to 30 years and can be put into long-term use at once, with high cost-effectiveness.

7.Non-Contact Process: Laser welding is a non-contact method, which means there is no physical contact between the welding tool and the workpiece. This eliminates the need for consumables or electrodes, reducing maintenance and tooling costs.

A laser welding machine is an eco-friendly welding tool that comes with a handheld laser gun, CNC controller, or single-arm robot to join pieces of metals or thermoplastics, which is frequently used in high volume applications with automation, which is based on keyhole or penetration mode welding.

Laser welders are widely used in manufacturing

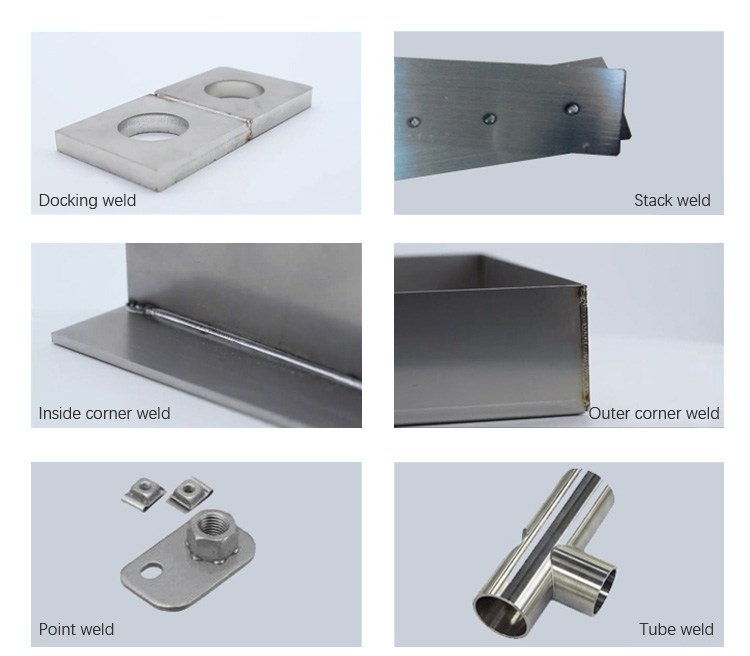

A laser welder is a thermal welding machine that uses the high heat energy from the laser beam to connect parts together, including spot welding, seam welding, lap edge, T butt, butt joint, lap joint, narrow welds, deep welds and kissing welds. It is typically used by manufacturing businesses in the engineering, medical and electronics industries, through to welding thicker materials in the automotive and aerospace industries. A laser welder is also known as laser welding gun, welding tool, seam welding machine, bonding machine, brazing machine, joining machine, soldering machine.

Metal laser welding machines find applications in various industries, including automotive manufacturing, aerospace, electronics, medical devices, and jewelry production. They are utilized for tasks such as sealing, spot welding, seam welding, and complex joint configurations.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.