Buyer Guide

Stainless Steel CNC Fiber Laser Cutting Machine 1500 Watt

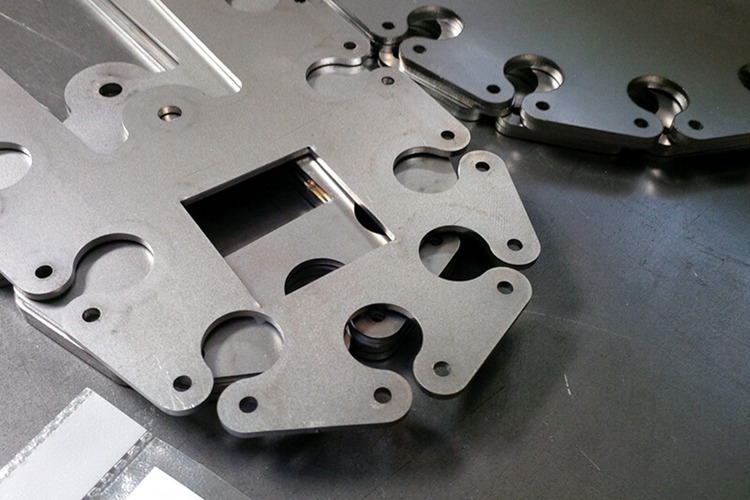

This is the stainless steel cnc fiber laser cutting machine, as a professional laser cutting machine, it can be used in many metal cut industry. The carbon steel fiber laser cutting machine is best at processing thin metal plates, not only has high processing speed, but also The quality is also high.

Laser cutting and engraving of metal is now one of the most economical, flexible and precise metalworking processes. All metals used in industrial processing are suitable for this purpose, with stainless steel accounting for a large proportion. Stainless steel laser cutting and laser engraving are used wherever complex geometries or industrial markings or even creative designs have to be implemented quickly, accurately and without force. The powerful and cost-efficient IGOLDENLaser laser cutters always convince with a low investment risk as well as high productivity rates and high-quality results.

This stainless steel cnc fiber laser cutting machine is specially designed for cutting sheet metal and many other materials. The machine has the advantages of low price, strong processing ability and good quality of accessories, and this carbon steel fiber laser cutting machine is widely used in the production of precision parts such as technology, digital products, electronic components, clocks, precision machinery, craft gifts and so on. Sheet metal cutting industry. This machine has been deeply loved by practitioners in the laser industry.

1500W optical fiber laser cutting machine adopts gantry structure, aluminum alloy beam, imported grinding rack, imported high-precision linear guide drive system, professional laser cutting CNC system and high-performance servo motor. It is a high-tech product integrating laser technology, precision machinery, CNC technology and other advanced technologies. The 1000W fiber laser cutting machine is mainly used for fast cutting of carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, brewing and washing sheet, aluminum and zinc plated sheet and other metal materials. The 1000 Watt laser cutter has the ability to resist high reflection and canapply cut on copper and aluminum. Industry application include sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, ships, metallurgical equipment, elevators, kitchenware, household appliances, craft gifts, tool processing, decoration, advertising, metal processing and other manufacturing and processing industries.

1500W Laser Cutting Machine Features:

1 Professional CNC control system can ensure the cutting quality, make the cutting work more convenient;

2 Gantry structure, high damping bed, high rigidity, can withstand high speed and acceleration;

3 Exchange workbench configuration, shorten standby time, effectively improve work efficiency by more than 30%;

4 The machine adopts imported AC servo system drive and imported transmission system, and the machine motion mechanism adopts imported rack and pinion drive and linear guide rail guidance, which ensures the high speed, high precision and high reliability of the equipment;

5 The rack and guide rail adopt the fully sealed protection device to prevent the oil-free friction movement and dust pollution, improve the service life of the transmission parts and ensure the movement accuracy of the machine tool;

6 The laser cutting head is equipped with imported capacitance non-contact height tracking system, which is sensitive and accurate, avoiding the collision between the cutting head and the processed plate, ensuring the cutting focus position and the stable cutting quality;

7 The laser cutting head can bear 2.0MPa gas pressure, which improves the cutting ability of stainless steel and other difficult cutting materials;

8 The machine has automatic partition smoke exhaust system, which has good smoke exhaust effect and low pollution;

9 Small area, highly integrated system, convenient operation and maintenance, meet the needs of 24-hour industrial production;

Stainless Steel CNC Fiber Laser Cutting Machine FAQ

Which is better for cutting stainless steel, CO2 or fiber laser?

In fact, both fiber laser and CO2 laser can be used to cut stainless steel.Fiber laser cutters are known for their high precision and fast cutting speed, cutting 2-3 times faster than CO2 lasers.

This makes it the ideal choice for more and more manufacturers who are eager to improve production efficiency.The operating cost of fiber laser cutter is usually 1/3 of C02, because it consumes less power and has high electrical efficiency.

They are also relatively low maintenance and have a longer lifespan compared to CO2 laser cutters.In short, fiber laser is a more cost-effective solution for cutting stainless steel.

How much does a stainless steel laser cutter cost?

The cost of a stainless steel laser cutter can vary widely depending on several factors such as the laser power, size, and capability of the machine. You can tell us the stainless steel thickness you need to cut and your other requirements, we will recommend the most suitable machine that fits your specific needs and budget.

Why use a laser to cut stainless steel?

Our stainless steel laser cutting machines

- Cleaner edges and no warping issues- The laser cutting process generates heat that affects a very small part.

- No maintenance- It is another reason for using laser technology for your regular stainless steel cutting projects.

- You can maintain precision while cutting your stainless steel

- The laser cutter also helps in retaining consistency in the laser-cut stainless steel.

- Within the shortest time, you can accomplish your metal cutting project.

Does laser cutting harden and distort stainless steel?

Laser cutting stainless steel does not typically result in hardening and distortion. The heat generated by the laser cutting process is localized and limited, and therefore does not cause significant changes to the overall mechanical properties of the stainless steel.

How fast does laser-cut stainless steel?

The thickness of your stainless steel sheet and the laser power can make a difference in the cutting speed. However, the cutting speed can be increased to 72mm/min to cut a stainless steel sheet of 60mm in thickness. The laser power can be around 6KW.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.