Buyer Guide

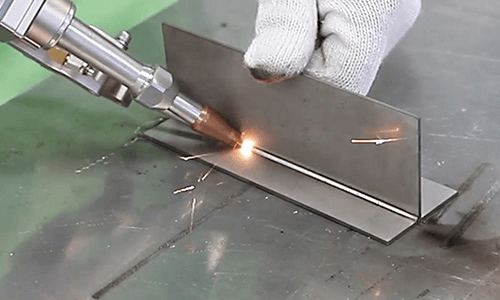

Stainless Steel Cabinet Tableware Laser Welding Machine

Kitchen utensils are used every day in our life, such as stainless steel pots and pans. But have you ever thought about how it is made? Kitchen utensils are made of various raw materials, some are ceramics, some are plastics, some are metal stainless steel. Today we are talking about metal stainless steel tableware. We know that the handheld laser welding machine is often used in the production process of kitchen utensils. To be exact, the hand-held stainless steel laser welding machine is used.

Stainless steel laser welding machine

Stainless steel laser welding machines are commonly used for applications such as welding thin sheets, precision components, medical devices, and other products where a high level of precision and control is required.

A stainless steel laser welding machine is a specialized tool used for joining pieces of stainless steel through the process of laser welding. Laser welding is a welding technique that uses a laser beam to melt and fuse metals together. It is a precise and efficient method that is commonly used in various industries, including automotive, aerospace, electronics, and medical device manufacturing.

Compared with argon arc welding, handheld laser welding machine saves 80% and 90% electric energy, and the processing cost can be reduced by about 30%. It can weld dissimilar steel and metal to realize mechanization and automation. High speed, small deformation, small heat affected zone, high aspect ratio. The weld is beautiful, flat and free of air holes. No treatment or simple treatment is required after welding. Small focus, no pollution, high positioning accuracy. The hand-held laser welding machine can be used for small opening parts and precision welding.

Welding Speed and Precision: Laser welding provides fast and accurate welding results. The laser beam can be precisely controlled to deliver high-speed welding with minimal heat input, minimizing material distortion and ensuring precise weld quality.

Advantages of handheld laser welding machine:

Now, there are more advanced welding equipment – hand-held laser welding machine. Compared with traditional welding methods, what are the advantages of hand-held laser welding machine?

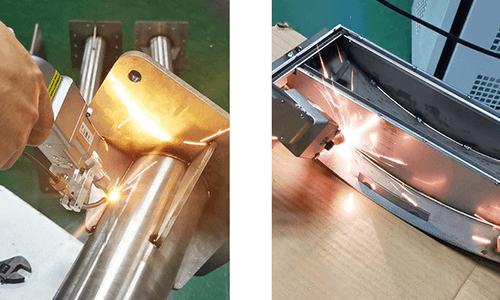

1. Simple operation: it can be welded by hand without expensive training cost.

2. Fast and efficient, wide processing range: handheld laser welding machine energy concentration, high welding efficiency, fast speed, smooth and beautiful weld, reduce subsequent grinding process.

3. Wide range of welding materials: stainless steel plate, iron plate, galvanized plate, aluminum plate and other metal materials can be welded.

4. It breaks through the limitations of workpiece shape and processing environment: small solder joint, small heat affected area, no need to set up welding workbench, small space occupation, flexible processing, fast welding speed, long-distance movement, not limited by environmental space.

5. Low maintenance cost: as long as the hand-held laser welding equipment is equipped with the hand-held laser welding joint, the welding operation can be completed, and the replacement cost of accessories is low. If you don’t know how to replace it, you can also go directly to the manufacturer for repair without worrying about the cost of transportation and after-sales service.

6. High performance price ratio: the hand-held laser welding machine not only can carry out the hand-held laser welding work, but also can carry out the high-precision welding repair of the mold through the later stage platform. It is the preferred high cost-effective welding production equipment for more small manufacturers.

Application range of fiber laser welding

Bathroom industry: three dimensional space curve welding of water pipe joint, reducer joint, tee joint, valve and sprinkler head. Battery industry: laser welding of lithium battery, battery pack and electrode. Glasses industry: stainless steel, titanium alloy and other materials of glasses buckle, outer frame and other positions of precision welding. Hardware industry: impeller, kettle, handle, etc., welding of complex stamping parts and casting parts.

When selecting a stainless steel laser welding machine, consider your specific requirements such as the thickness and type of stainless steel to be welded, the desired welding speed, and the expected production volume.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.