Laser Knowledge

How Does Laser That Removes Rust Work

Can you Laser That Removes Rust ?

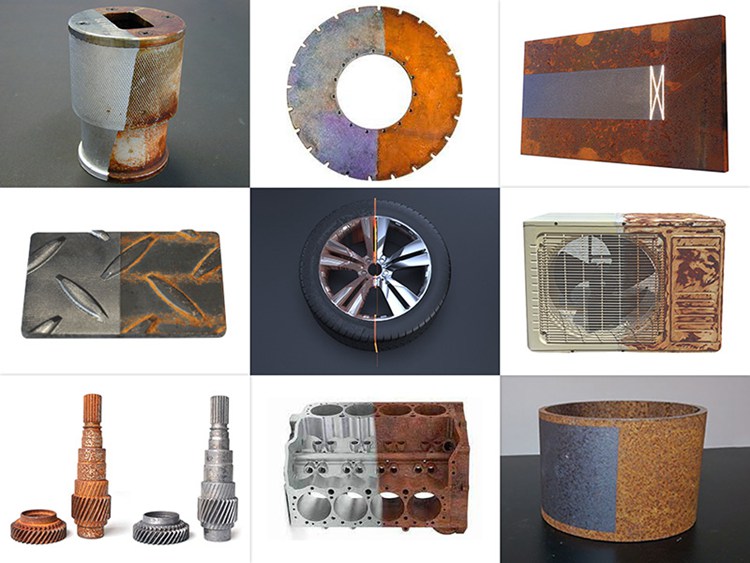

Yes, it is possible to remove rust with a laser using a process known as laser rust removal or laser cleaning.Using a laser to remove rust is a method known as laser rust removal or laser cleaning. It’s an effective and precise technique, often used in industrial settings.The laser emits high-intensity light that is absorbed by the rust, causing it to heat up rapidly. The heat disrupts the bond between the rust and the underlying metal surface.Unlike traditional methods such as abrasive blasting or chemical treatments, laser rust removal is non-abrasive and doesn’t involve the use of chemicals, making it a more environmentally friendly option.

Rust removing laser process typically works?

- Laser Beam: A high-powered laser beam is directed onto the rusted surface. The laser emits a focused beam of intense light energy.

- Absorption: The laser beam is absorbed by the rust layer on the surface. The energy from the laser beam causes the rust to heat up rapidly.

- Vaporization: As the rust layer absorbs the laser energy, it vaporizes and turns into a gas. The rapid vaporization causes the rust layer to be ejected from the surface.

- Cleaning Process: The ejected rust particles and contaminants are then captured using a dust extraction system or vacuuming system.

- Surface Cleaning: The laser cleaning process is repeated until the desired level of rust removal is achieved. The laser beam is moved across the surface, systematically removing rust from the entire area.

Advantages of Laser Rust Removal

Laser rust removal offers several advantages over traditional rust removal methods, including:

Non-Destructive Cleaning

Laser rust removal is a delicate and non-destructive process that can be set up to remove surface contamination only leaving the substrate below untouched. A more aggressive approach can be taken as well in the case that is desired by simply adjusting the laser parameters and delivery optics.

Traditional methods, such as sandblasting or chemical cleaning, can remove a small amount of material from the surface, leading to deformation or warping. This can be especially problematic for delicate or intricate metal parts that cannot be subjected to harsh treatments. Laser rust removal is ideal for these types of parts as it can be adjusted to eliminate any damage to the underlying material. In addition, the laser beam can be controlled to remove rust in a precise location and depth, making it ideal for cleaning fragile or complex components.

Environmentally Friendly

Laser rust removal is a clean process that does not require the use of chemicals, solvents, or abrasive materials. It produces minimal waste and does not generate harmful fumes or dust.Laser rust removal is a clean and environmentally friendly process that does not require chemicals or other hazardous materials. Traditional rust removal methods often involve using chemicals that can harm the environment and human health. Laser rust removal produces no waste and does not generate any harmful byproducts. This makes it a safer and more sustainable alternative to traditional methods. Also, because it does not require any chemicals or other consumables, laser rust removal can save costs over time.

Faster Cleaning

Laser rust removal is a fast and efficient process that can remove rust from metal surfaces in a fraction of the time required by traditional methods. This can lead to significant cost savings and increased productivity in industrial applications. Furthermore, laser rust removal can be performed in situ, which means that parts do not need to be removed from the production line for cleaning. This can save time and reduce downtime in industrial processes, making it a popular choice for industries where time is of the essence. Also, because laser rust removal is so fast, it can be used for large-scale cleaning projects, such as bridges, without causing significant disruptions to traffic or other activities.

In addition to these advantages, laser rust removal can also improve the performance and longevity of metal parts by removing rust and other contaminants that can cause corrosion or other forms of damage.

Precision Cleaning

Laser rust removal is a highly precise process that can remove rust from specific areas of a metal surface without affecting the surrounding material. This makes it ideal for cleaning parts requiring high precision, such as medical equipment, aerospace components, or high-precision machinery. In addition, the laser can be controlled to remove rust in a specific pattern or shape, allowing for highly precise cleaning. This precision makes laser rust removal a popular choice in industries where accuracy is critical. It is also a popular choice for historical artifact restoration, where preserving the original material is of utmost importance.

Versatilit

Laser cleaning can be applied to various materials and surfaces, including metals, stone, ceramics, and more. It can effectively remove rust, oxides, paint, coatings, and other contaminants.

What is Laser Rust Removal?

Laser rust removal is a non-contact cleaning process that uses a laser beam to remove rust, oxide layers, and other contaminants from surfaces. It is an innovative and efficient method for cleaning metal surfaces, gaining popularity due to its non-destructive nature and precision cleaning capabilities.

The concept of laser rust removal can be traced back to the 1980s, when lasers were first used for cleaning delicate surfaces in the aerospace industry.

Since then, the technology has been refined and applied to various industrial and commercial applications.

As a result, laser rust removal has gained prominence in recent years due to its ability to clean rust without damaging the surface of the metal.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.