A laser metal cleaner, also known as a laser rust remover or laser cleaning machine, is a device that uses laser technology to remove rust, paint, coatings, and other contaminants from metal surfaces. It offers a non-contact, precise, and efficient method for cleaning metal without the need for chemicals or abrasive materials.

Laser Metal Cleaning

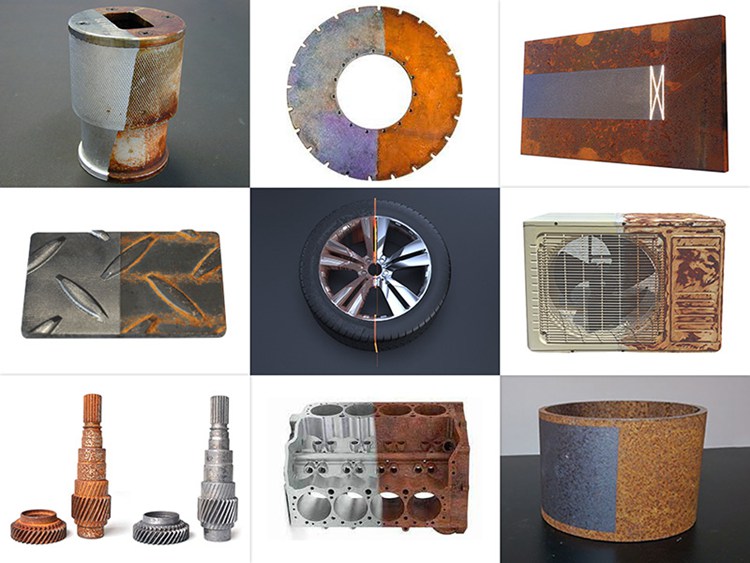

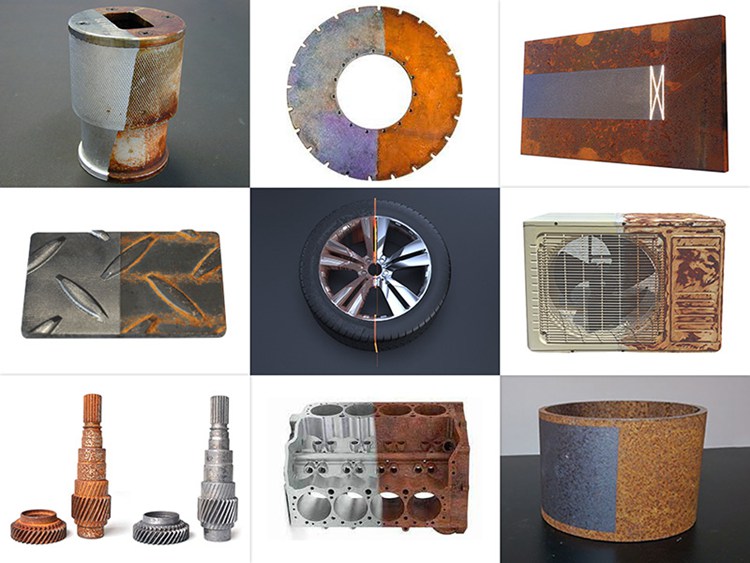

Laser metal cleaning are effective on various types of metals, including steel, iron, aluminum, copper, brass, and more. However, the effectiveness may vary depending on the specific metal and the properties of the contaminants to be removed. It’s advisable to check the machine’s specifications and capabilities to ensure it is suitable for the particular metal you intend to clean.

Laser cleaning is considered an environmentally friendly method as it does not involve the use of chemicals or generate hazardous waste. However, it’s important to consider proper ventilation and capture systems to handle the vaporized debris generated during the cleaning process.

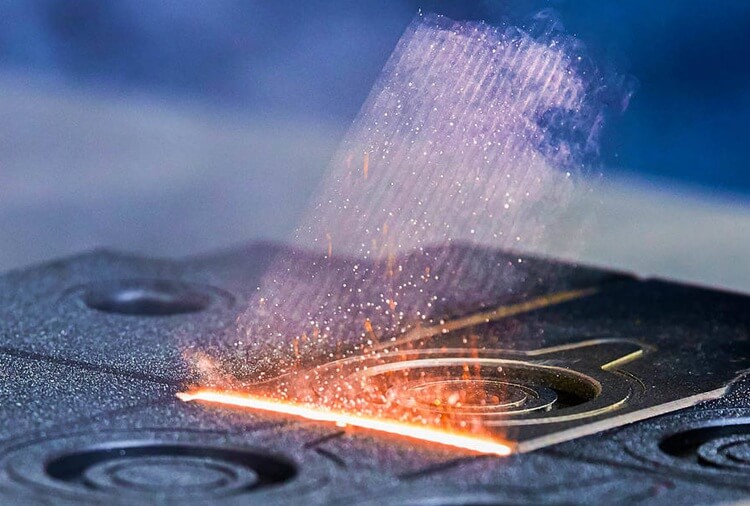

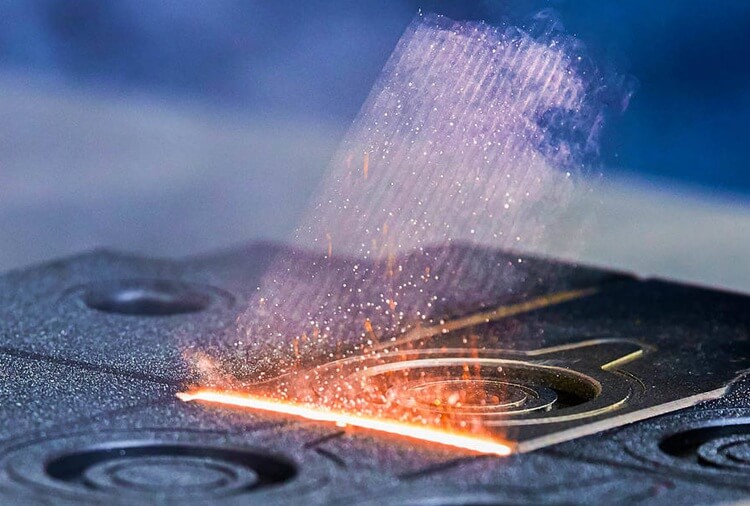

Laser metal cleaners use high-intensity laser beams to vaporize or ablate the contaminants on the metal surface. The lasers can be of different types, such as fiber lasers, pulsed lasers, or continuous-wave lasers, depending on the specific application requirements.

The laser beam interacts with the surface contaminants, such as rust or paint, causing them to heat up rapidly. The rapid heating creates a thermal shock that leads to the vaporization or disintegration of the contaminants, leaving the underlying metal surface clean.

Laser metal cleaners offer precise control over the cleaning process. The intensity and focus of the laser beam can be adjusted to target specific areas or remove specific layers of contaminants. This allows for selective cleaning without damaging the underlying metal surface.

Laser Metal Cleaner

Laser metal cleaner is a kind of laser rust removal equipment adopting laser cleaning system through high power fiber laser beam to laser evaporate metal rust, paint, oxides, coating, grease, and oil stain on different material surfaces like steel, aluminum, stone, and rubber.

IGOLDENLASER offer laser power options of 50W, 100W, 200W, 300W, 500W, 1000W, 1500W, 2000W, 3000W and 6000W. With different configurations, these fiber laser machines complete jobs quickly with high-level precision.

The process of laser cleaning is non-contact and non-abrasive, which makes it ideal for delicate or sensitive materials that could be damaged by traditional cleaning methods. It is also a very precise method of cleaning, allowing for selective removal of contaminants without damaging the underlying material.It is also known as laser cleaner, rust removal machine, paint stripping machine, coating removal tool, oxide remover, oil cleaner, dirt cleaning system, laser descaler machine.

Laser metal cleaners can be integrated into automated systems or robotic arms for efficient and repetitive cleaning tasks. Some machines may also offer scanning heads or motion control systems to provide automated and uniform cleaning across large areas.

Robot Cleaning Machine Advantages

- Robot six-axis linkage, high positioning accuracy, large processing range, easy to achieve all kinds of workpiece cleaning;

- High-end standard laser head, a variety of cleaning modes, can achieve precise position, precise size selective cleaning;

- Using non-contact cleaning, non-contact cleaning, no damage to the parts matrix, fast cleaning speed, high precision;

- No chemical cleaning solution, no consumables, safety and environmental protection;

- They are used in automobile manufacturing, machining, electronic processing, heritage restoration, die and mold industry, shipping industry, food processing, petrochemical industry, etc.

Application of Fiber Laser Cleaning Machine

> Rust removal on metal surface;;> Surface paint removal treatment;

> Surface resin, oil, stains, dirt cleaning;;> Surface coating, coating removal;

>Pretreatment of welding surface/spraying surface; > Removal of dust and attachments on the surface of stone statues;

> Rubber mold residue cleaning.

More and more companies and individuals want to buy a laser cleaning machine to support their business. How to buy a suitable laser cleaning machine that fits your needs? You can follow the below three steps.

- First of all, contact with a qualified manufacturer that has profound experience in the manufacturing of laser cleaning machines. A reliable manufacturer not only produces high quality laser cleaning machines, but also provides you complete machine data and thoughtful after-sales service. Before you buy a machine, it is essential to inspect the factory and check the real cleaning effect of the machine.

- In addition, check the machine’s appearance. The design, structure and manufacturing process can almost directly determine the quality of the machine. The design style of each manufacturer is different. A manufacturer that has mature production technology always continuously improve the machine’s appearanceand structure under the premise of ensuring quality.

- Choose the machine according to your needs and budget. Tell the salesperson about your cleaning requirements and budget plan, and they will recommend the suitable machine and configure the parameters, machine size and parts. Let the salesperson know your detailed processing requirement (processing materials, cleaning speed, etc.) so that you can get a most cost-effective laser cleaning machine.

Before investing in a laser metal cleaner, evaluate your specific cleaning needs, budget constraints, and production requirements. Consider factors such as laser power, beam delivery options, control interface, and support services offered by the manufacturer to select the most suitable solution for your metal cleaning applications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.