Laser Knowledge

How Much Does Laser Cutting Machines Cost?

How much does the tube laser cutting machine cost? When customers purchase and consult a laser pipe cutting machine, they will first consider the cost of the laser pipe cutting machine, and then the after-sales service of the laser pipe cutting machine. The price problem of laser pipe cutting machine includes many factors: laser, cutting head, consumables, lenses, service, freight and technology.

Two classifications of tube laser cutting machine chucks

The laser pipe cutting machine has two configurations: manual chuck and start chuck. The functionality of the chuck is different, and the price is also very different.

Regarding the price of the laser pipe cutting machine, you can’t just look at the cheapness, but not the manufacturer’s quality, after-sales and technical capabilities. I hope that when customers buy equipment, they can buy a laser pipe cutting machine that suits them by comparing them.

What is a tube laser cutting machine?

The tube laser cutting machine can cut square tubes, round tubes and oval tubes, etc., all of which can be cut. The second is to consider the wall thickness and length of the tube, which determines the length and power of the laser tube cutting machine.

The thicker the wall thickness of the tube, the greater the laser power required, and the higher the price. The longer the length of the machine tool, the higher the cost and the higher the price.

What should I pay attention to when purchasing a tube laser cutting machine?

1.Consider processing requirements

The laser cutting machine is used to cut flat plates or pipes. If it is a simple pipe cutting and there is also a need for sheet cutting, you can choose a plate-tube integrated laser cutting machine. If the requirements for pipe processing are relatively high, the pipe is cut and punched. Hole, cutting graphics, etc., you can choose CNC laser pipe cutting machine.

2.The influence of the brand

There are many laser pipe cutting machine manufacturers in China. Each manufacturer’s strength, engineer’s technology and after-sales service capabilities are different. The overall performance of the equipment is also very different. It is recommended to visit the manufacturer to see the effect of on-site cutting and compare with each other a bit.

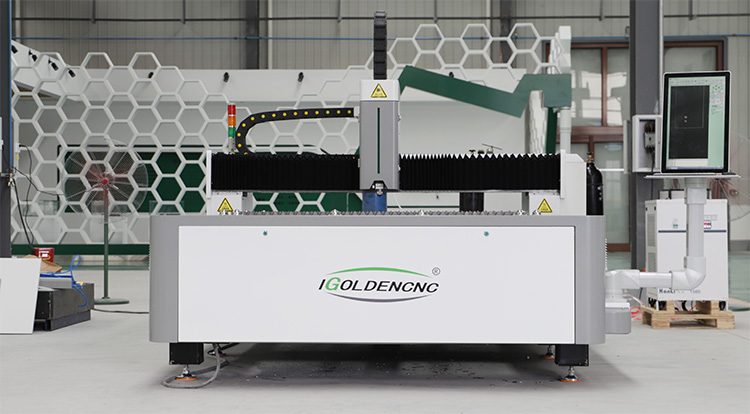

Affordable CNC Metal Laser Cutting Machine For Sale

or many newcomers want to buy CNC laser cutting machine who do not know how to select CNC laser cutting machine, Igolden sell most affordable laser CNC laser cutting machine, fiber laser cutting machine specifications 1000-20000w are the most affordable CNC laser cutting machine Suppliers, now I will introduce the laser cutting machine.

How much is a metal laser cutting machine

The fiber laser cutting machine has also analyzed the processing cost for everyone before. The processing cost per hour for the 850W solid laser cutting machine to cut 1mm stainless steel (using air) is about 50,000 US dollars, and the 500W fiber laser cutting machine cuts 1mm about 110,000 US dollars. The processing cost of stainless steel (using oxygen) is $3.

If there is a lot of business, we calculate it based on the non-stop operation 24 hours a day. The solid-state laser cutting machine costs US$112 per day, and the fiber laser cutting machine costs US$42 per day. The daily output value of the solid laser cutting machine can reach 1900 yuan, the fiber laser cutting machine can reach 52 US dollars, and the labor is 33 US dollars per day.

As the brand of Chinese laser cutting machines becomes stronger, the competition between products and enterprises is no longer a single price competition. Hidden elements such as quality, service, added value, channels, and enterprise development strategies are also the long-term development of enterprises and brands. An important aspect of a sustainable development competition.

Cutting machine cost recovery time: 133333/418≈281 days; the above is an ideal processing estimate, but according to the actual customer’s response and the business processing volume is relatively large, the cost recovery time of the 850W solid-state laser cutting machine is 1 About half to two years. The cost recovery time of 500W fiber laser cutting machine is about 2 to 2 years.

Which industries are metal laser cutting machines used in?

Laser cutting machines are widely used in personalization, digital printing, medical technology, Fablabs, education, architectural models, smart phones and laptops, computers and electronic products, toys, watches, crafts, awards, trophies, rubber stamps, packaging design, molds Cutting, mold making, sign making, display making, gifts, electronics industry, automotive industry, signage, mechanical engineering, ball bearings, jewelry making, fashion and clothing fabrics, wax paper, paper cards, car floor mats and linings, textiles and clothing Industry, barcode serial number, watch, machining industry, data nameplate industry, packaging industry.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.