Buyer Guide

Carbon Steel Laser Cutting Machines

Versatile fiber laser cutting machines in a range of formats and capacities capable of processing thin to thick ferrous and non-ferrous materials to high production laser tube cutting machines, all with performance-enhancing options, as well as laser automation.

Fiber Laser Cutting Machine suited for sheet metal processing. Such as various metal products processing industries, agricultural machinery industry, automobiles, aircraft and ships, electrical equipment, lighting advertising industry, elevator manufacturing, kitchen electrical appliances and so on.

The use oflaser cuttinghas the advantages of fast cutting speed, high production efficiency, good cutting quality, narrow slit, good material adaptability, no tool wear, no matter it is simple or complex parts, it can be precisely and quickly formed and cut at one time, with a high degree of automation and simple operation. Low labor intensity, no pollution, low noise, low production cost, can save a lot of manpower and material resources, and good economic benefits.

Laser cutting uses a high-energy-density laser to instantly vaporize the processed material, and discharges the vaporized material through an auxiliary gas to form an incision, so as to achieve the purpose of cutting. Therefore, laser cutting is a non-contact cutting process. Different materials and parts do not need to change tools, and it is easy to achieve automatic high-speed cutting. The laser cutting machine adopts numerical control operation. After the shape to be processed is formed in the computer, the source code is automatically generated through the nesting software, so that the instant proofing can be realized, and the production can be produced immediately after confirmation, and the production cycle can be shortened. The use of laser cutting has the advantages of fast cutting speed, high production efficiency, good cutting quality, narrow slit, good material adaptability, no tool wear, no matter it is simple or complex parts, it can be precisely and quickly formed and cut at one time, with a high degree of automation and simple operation. , Low labor intensity, no pollution, low noise, low production cost, can save a lot of manpower and material resources, and good economic benefits.

Advantages of Laser Metal Cutting Machines

1. High power and high-quality laser output

High electro-optical conversion efficiency, flat-top distribution of light spot energy, and high energy density. The signal transmission takes the form of electricity-optical-electricity, and the light-emitting part and the light-receiving part are not in contact, which can avoid possible feedback and interference from the output end to the input end;

2. High efficiency and strong processing ability

The cutting effect is good, it can cut thicker plates, and the cutting efficiency of thin plates is higher. In the metal processing industry where the industrial manufacturing system accounts for a heavy share, many metal materials can be cut without deformation regardless of their hardness.

3. High reliability, long life, compact structure, maintenance-free

It has the advantages of durability, high reliability and fast speed, modular design, highly integrated system, stable operation and fewer failures. The response time is fast, and the response time of high-speed photocouplers is even less than 10ns.

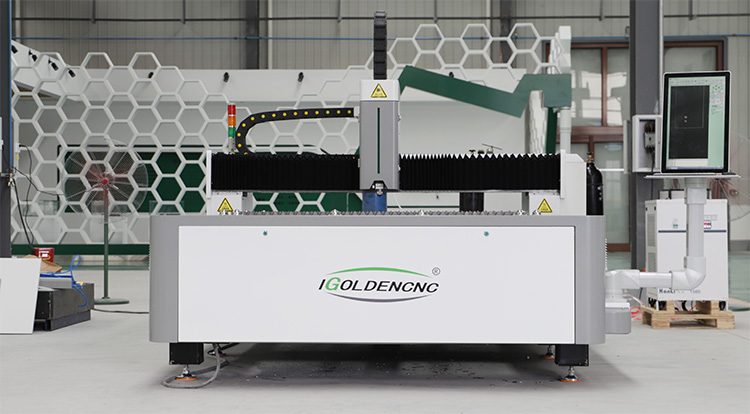

Cnc sheet metal laser cutting machine flatbed description:

Fiber laser cutting machines have been put into use very well. To solve this problem. The fiber laser cutting machine not only has a high-quality and stable processing range, which is suitable for both thickness and thickness, but also improves the cutting efficiency, especially the cutting speed of stainless steel and aluminum plates, and ensures low operating costs per unit time.

At present, fiber laser users care the most about how to improve efficiency and lower cost, fiber laser cutting machines, with desirable cutting speed, much less deformation and high precision, become mainstream cutting products in a very short time. High-power laser source greatly improves the processing efficiency, the speed of thin sheet cutting has been close to the control limit of machinery performance, and thick sheet cutting also sees a lot of breakthroughs.

Carbon steel is an alloy formed by iron and carbon, and carbon makes around 0.02%-2.11% of its total mass, there are also elements such as silicon, manganese, sulfur and phosphorus in carbon steel. In theory, more carbon brings higher hardness and strength but lower plasticity.

The advantages of fiber laser cutting machines in cutting carbon steel lie in many aspects. Firstly, the cutting quality is desirable, cutting surface is smooth, and there is no need for re-process. Secondly, the cutting speed is fast, greatly improving working efficiency. Then, the output power is stable, and laser source has long service life and easy maintenance. And the strong software function is another advantage. With the software, users can design all sorts of graphics and words, and the software is easy to operate.

For carbon steel processing, the most important part is to ensure the precision, especially for hardware parts which are used on automobiles, ships, precision accessories and home appliances. And the low cost and high efficiency are also key factors. The labor force is getting smaller, automation and smart devices are gradually becoming mainstream, so the laser equipment which can save manual labor and improve efficiency will definitely win the spotlight of the market.

Sheet Metal Fiber Laser Cutting Machine Applicable Industries

Our fiber laser cutting machine is suitable for cutting carbon steel, stainless steel, alloy steel, spring steel, aluminum, copper, brass, galvanized iron, etc., and has been widely used in the processing of metal sheet fabrication, steel furniture, fire pipes, automotive, fitness equipment, agricultural and forestry machinery, food machinery, advertising, electrical cabinets, elevators and other industries.

IgoldenLaser innovates and upgrades the laser cutting technology accumulated over the years, launches a variety of advanced laser cutting equipment, provides efficient and professional laser sheet metal processing solutions for the sheet metal processing industry, and ultimately maximizes the value of customers.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.