Buyer Guide

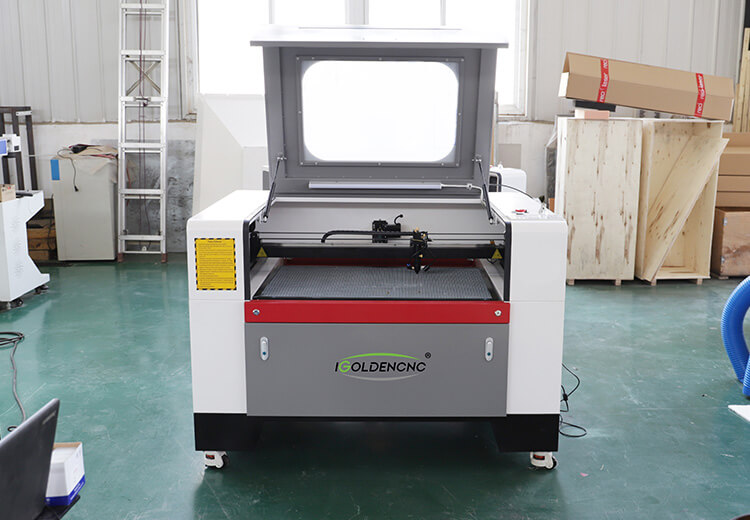

80w CO2 Laser Engraving Cutting Machine

iGOLDENCNC is the world-leading laser equipment manufacturer and service provider with a worldwide sales and service network and a broad network. Product resources guarantee that we can provide the most advanced laser technology and professional customer service. Over the past three years, we have provided a variety of cutting solutions for a wide range of industries, 2 years warranty is the best guarantee.

A variety of working formats are available, which can effectively fit the processing needs of various industries and specifications. And we can also customize the cutting format suitable for the specific production needs.

80w CO2 Laser Engraving Cutting Machine

CO2 DC glass laser tube or RF metal laser tube are optional according to industry and processing requirements. Our CO2 laser cutting machines can be equipped with 80w,100w, 150w, 200 watts, 300w, 600w, 800 watts and even a high-power CO2 laser.

An 80W CO2 laser engraver typically consists of a laser tube that generates the laser beam, a series of mirrors and lenses to direct and focus the beam, and a control system to manage the engraving process. The laser beam emitted by the CO2 laser is invisible to the naked eye but can accurately vaporize or burn away material to create precise engravings or cuts.

80W CO2 laser engraver refers to a laser engraving machine that utilizes a 40-watt carbon dioxide (CO2) laser tube as its primary source of energy for engraving and cutting various materials. CO2 laser engravers are versatile tools widely used for engraving and cutting a variety of materials, including wood, acrylic, leather, paper, fabric, glass, and certain types of plastics.

The 80W rating indicates the power output of the CO2 laser tube. Higher wattage generally allows for faster engraving and cutting speeds and the ability to work with thicker materials.

A laser engraving and cutting machine is a device that uses a high-powered laser beam to etch or engrave various materials such as wood, acrylic, leather, and plastics, and even cut through thinner materials. It works by directing the laser beam through a series of mirrors and lenses, which focus the beam to a precise point on the material being engraved or cut. The focused beam vaporizes or melts away the material, creating a desired pattern or shape.

Carbon dioxide laser is a gas molecular laser, the working substance is CO2 gas, auxiliary gases are nitrogen helium, xenon and hydrogen, etc., because the energy conversion efficiency of this laser is as high as 25%, it is often a high-power output laser, carbon dioxide laser wavelength 10.6 microns, is impossible to see infrared light, good stability, widely used.

Here are some key points about CO2 laser engraving cutting machine :

80w Laser Source

Using Beijing RECI laser tube, high-end, stable performance, uniform spot distribution, high work efficiency.These machines utilize a CO2 laser tube as the energy source.

Laser Engraving

CO2 laser engraving machines use the laser beam to vaporize or remove the surface layer of a material, creating detailed and precise engravings. They can engrave various materials such as wood, acrylic, leather, fabric, paper, glass, stone, and certain plastics.

Laser Cutting

CO2 laser cutting machines use the laser beam to melt or vaporize the material along a predetermined cutting path. This allows for precise and clean cuts in materials like acrylic, wood, plywood, MDF, rubber, fabric, leather, and certain plastics. However, they are not suitable for cutting metals.

Working Area and Table

CO2 laser machines come in various sizes, with different working areas to accommodate different material sizes and project requirements. The machine usually has a table or platform where the material is placed for engraving or cutting.

Precision and Speed

CO2 laser machines offer excellent precision and speed. The focused laser beam allows for intricate and detailed designs, while the high-speed cutting capabilities enable efficient production. The precision and speed can be adjusted based on the material and desired outcome.

Software and Control

Display preview graphics and processing status, can run independently, and work stably and reliably.

Material Compatibility

CO2 laser machines can work with a wide range of non-metallic materials. In addition to the materials mentioned earlier, they can also engrave or cut materials like cork, rubber, foam, paperboard, ceramic, and more. However, materials with high reflectivity, such as mirrors or certain metals, are not suitable for CO2 lasers.

Safety Features

Safety is an important aspect when using CO2 laser machine. They usually feature protective enclosures with safety interlocks to prevent accidental exposure to the laser beam. Additional safety measures may include laser power control, ventilation systems to remove fumes, and warning indicators.

Applicable Industry

CO2 laser engravers are widely used in various industries and for numerous applications. Some common applications include:

- Personalization and customization: CO2 laser engravers are commonly used for engraving personalized items such as trophies, awards, plaques, and gifts.

- Signage and labeling: They are used to create precise and detailed engravings on signs, labels, nameplates, and tags.

- Arts and crafts: CO2 laser engravers are popular among artists and hobbyists for creating intricate designs on materials like wood, acrylic, and paper.

- Industrial manufacturing: They are used for cutting and engraving materials in industrial settings, such as fabric cutting, gasket production, and part marking.

Applicable Material

Material Compatibility: CO2 laser engravers can work with a wide range of materials. Some commonly engraved or cut materials include:

- Wood: CO2 lasers can engrave or cut various types of wood, including plywood, MDF, solid wood, and veneer.

- Acrylic: Acrylic is a popular material for laser engraving due to its ability to produce clear, high-contrast engravings.

- Leather: CO2 lasers can create detailed engravings on leather, making them suitable for customized leather goods.

- Fabric: Textiles like cotton, polyester, and denim can be engraved or cut with CO2 lasers for applications like custom apparel or textile art.

- Glass: CO2 lasers can create frosted or etched effects on glass surfaces, adding a decorative touch.

Laser cutting machines can cut a wide variety of industrial materials of varying thickness to just about any shape. Quick, clean, accurate and adaptable, laser cutting is the preferred method for many businesses across a wide range of industries. Small features, sharp corners, and closely spaced features are all handled more easily by laser cutting than by conventional milling or punching.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.