Buyer Guide

1325 Mix Laser Cutting and Engraving Machine

Mixed laser cutting and engraving machine

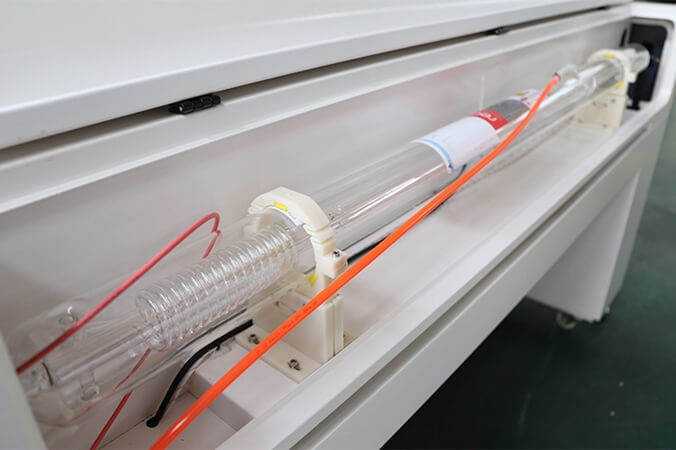

The hybrid laser cutting machine is not just a simple mixture of a CO2 laser and an engraver, but a completely new kind of machine which can process non-metallic materials and thin metal plates at the same time. The Mixed laser cutting machine is suitable for processing a variety of materials like wood, acrylic, leather, sponge and so on. It also applies to some metal materials with a thickness ≤ 3mm such as stainless steel plate, carbon steel plate, galvanized plate and titanium plate. Our newly developed 1325 mix laser cutting and engraving machine is equipped with high-power CO2 laser tubes of 150w/300w/500w/600w to meet different design requirements in different industries.

This machine is newly designed model to meet the increased requirements of using co2 laser tube to cut both metal and nonmetal materials.It has special designed machine structure and laser head,with thehelp of the oxygen gas,to obtain good metal and nonmetal cutting result.

Unique oxygen gas control systerm refrain you from worrying about how to control the gas during cutting. And compared with some other laser use only for metal cutting like fiber,YAG,this machine has largecutting material area,and more reasonable price,it is a good choice for all the customers who want to do cross industry business.

Non-contact height-adjusting configuration enables to cut almost all materials with lowest cost.

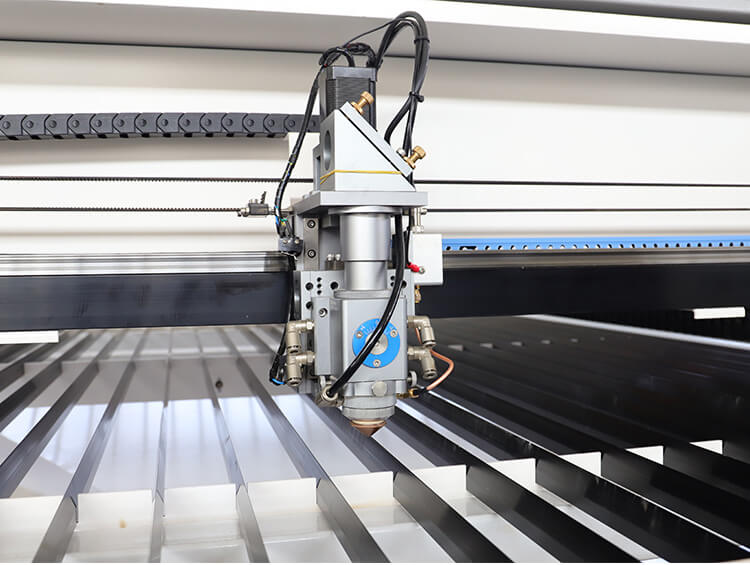

Moving system adopts Taiwan ABBA linear guide and precision belt, matched up with advanced DSP Panel controlled 3-phase stepper motor to ensure the working accuracy.

High efficiency Reci laser tube with stable laser path, life time around 10,000 hours.6. Working table: Open blade with special treated material. Never fray and easy operation, suitable for all kinds of hard materials.

Mix Laser Cutting and Engraving Machine Features

1.Outstanding cutting cross section, high precision, good stability, satisfying the process demands of precision parts. Dynamic performance is stable, able to work for long time.

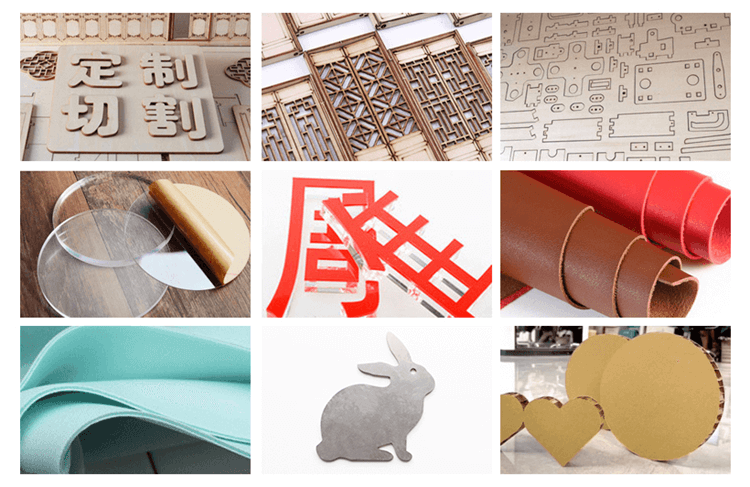

2.Capable of cutting both non-metal and metal, able to cut stainless steel, carbon steel, acrylic and wood, etc.

3.Laser cutting head with auto focusing system. Laser cutting head automatically adjust its height along the metal sheet surface, ensuring the focal length keeps the same all the time. Smooth cutting edge, no need polishing or other further handling. Flat and wavy steel sheets can be cut with this machine.

4. High efficiency: The cutting speed of 1mm stainless steel is 30 mm/s.20mm acrylic with perfect cutting quality.

5.1325 Laser cutting machine is matched with the stepper motor system or Panasonic Servo System and high precision..

6.High efficiency, high precision, stable performance and long life.Low running cost about 3-5KVA/hour

Mix Laser Cutting and Engraving Machine Application Scenarios

The 1325 Mix Laser Cutting and Engraving Machine is suitable for cutting and cutting various non-metallic and metal sheets such as wood, MDF, acrylic, plywood, stainless steel, carbon steel, galvanized steel, etc. It is widely used in signs, models and advertising applications.

Applicable

1.Mainly used in large plastic character cutting ,color plate engraving and cutting ,sign engraving, crystal engraving, trophy engraving, authorzation engraving etc.

2.Leather clothing processing industry: can engraving and cutting complex patterns on genuine synthetic leather, woolens, clothing, furnishing, glove, handbag, model and Aircraft Model, etc.

3.Model industry: production of construction sand table model and Aircraft Model, etc. ABC plate cutting ,MLB cutting.

4.Packing industry: Engraving and printing rubber plate, plastic, duble board, die cut paper, etc

The specific application scenarios are as follows:

What are the Advantages of a CO2 Laser Machine?

1.Wide range of processing: CO2 laser engraver can engrave and cut almost any non-metal material and has a very wide application in manufacturing industry, art industry, and medical industry.

2.Safe and reliable: adopting non-contact processing, CO2 CNC laser cutter for sale will not harm the surface of the machined part or deform the material.

3.Eco-friendly: the diameter of beam and spot is small generally less than 0.5mm, it has the features of material saving, safety and environmental protection.

4.High-speed and fast: it can immediately perform high-speed engraving and cutting according to the drawings output by the computer.

5.Low cost: it has low maintenance costs and only needs inexpensive replacement parts. Especially for small batch processing services, laser processing is cheaper.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.