Laser Knowledge

What is Metal Laser Engraving?

Metal laser engraving is a process that uses a high-powered laser to etch images or text into the surface of metal objects. It is a fast and precise way of marking metal and can be used on any metal, including stainless steel, aluminum, brass, and titanium.

Metal laser engraving works by focusing a laser beam onto a metal surface. The beam then vaporizes the metal and creates a crisp and permanent image or text. The laser beam can be adjusted to produce different engraving depths; in some cases, the beam can also be used on thin metal objects.

Metal Laser Engraving

The resolution of the laser engraving is extremely high, allowing for sharp and detailed images that are easy to read and look great.

Additionally, the process does not require a high level of skill or experience, as all the user needs to do is set up the laser and design. It makes it ideal for mass production or large-scale projects. As well as producing professional-looking designs, metal laser engraving is incredibly durable.

The engraving will not fade or wear away over time, so that it can last for years with no signs of deterioration. Additionally, the engravings can withstand extreme temperatures and harsh environments, making them perfect for outdoor or industrial applications.

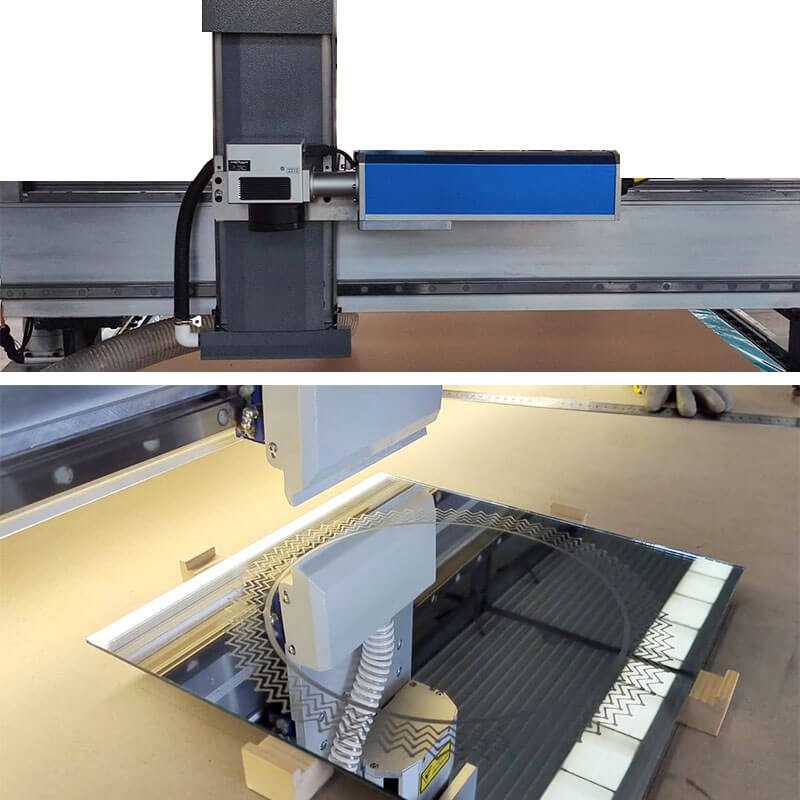

CO2 Laser Engravers

CO2 laser engravers are the most popular type of laser engraver. They’re often used for things like signage, branding, and art. CO2 laser engravers use a gas mixture of carbon dioxide, nitrogen, and sometimes helium.

This gas mixture is then turned into a plasma state by an electrical discharge. The plasma is then passed through a nozzle, which creates a laser beam.

Fiber Laser Engravers

This type of laser engraver uses a fiber optic cable to create the laser beam. The fiber optic cable is made up of thousands of tiny glass fibers. When electrically charged, these fibers create a laser beam. Fiber laser engravers are often used for things like industrial applications and product labels.

In general, fiber laser engravers are more powerful than CO2 laser engravers. For example, they can engrave metal at a much faster rate.

Metal Laser Engraving Uses!

Now that you understand how metal laser engraving works, it’s time to take a look at some of the most common uses for this technology. Below, we’ll discuss 10 most popular uses for metal laser engraving.

1. Identification Tags

One of the most common uses for metal laser engraving is creating identification tags. This includes things like dog tags, key chains, and nameplates. It’s a great way to add a personal touch to something that is otherwise very plain.

2. Jewelry

Another popular use for metal laser engraving is creating jewelry. For example, you can use it to engrave a special message on a ring or necklace. When done correctly, metal laser engraving can create a very beautiful and unique piece of jewelry. No two pieces will ever be exactly alike.

3. Awards

Metal laser engraving is also commonly used to create awards and trophies. You can use it to engrave the recipient’s name, the date, and a special message. This is a great way to create a truly unique and special award. Even if two people receive the same award, their engraving will be entirely different. Also, because the engraving is done with a laser, it will be extremely precise and look very professional.

4. Gifts

If you’re looking for a unique gift, metal laser engraving is a great option. You can use it to engrave a special message or design on just about anything. This is a great way to create a one-of-a-kind gift that the recipient will cherish for years to come. With metal laser engraving, the possibilities are endless. You can really let your creativity run wild.

5. Signage

Another common use for metal laser engraving is creating signage. This includes things like office signs, directional signs, and warning signs. Many businesses use metal laser engraving to create high-quality and professional-looking signage.

6. Branding

Branding is a very important part of any business. And one great way to brand your business is with metal laser engraving. You can use it to engrave your company logo or name on just about anything. This is a great way to make your brand more visible and recognizable.

7. Art

Metal laser engraving can also be used to create art. This includes things like sculptures and paintings. If you’re an artist, metal laser engraving is a great way to create unique and one-of-a-kind pieces.

8. Promotional Items

Promotional items are a great way to get your brand out there. And with metal laser engraving, you can really make your promotional items stand out. For example, you can engrave your company logo on pens, keychains, and other small items. Then, when people use these items, they’ll be reminded of your brand.

9. Nameplates

Nameplates are another common use for metal laser engraving. When engraved with a laser, nameplates look very professional. They’re often used for things like office doors, cubicles, and name badges. A new trend is to use metal laser engraving to create personalized nameplates.

For example, you can have your name and title engraved on a nameplate. This is a great way to make a good first impression.

10. Product Labels

Last but not least, metal laser engraving can also be used to create product labels. Without product labels, it would be very difficult to identify products. And with metal laser engraving, you can create high-quality and professional-looking labels.

The uses for metal laser engraving are really only limited by your imagination. These are just a few of the most popular uses for this technology. No matter what you’re looking to create, metal laser engraving is a great option.

How To Choose The Right Laser Engraver for Metal?

There are a few things you’ll want to keep in mind when choosing a metal laser engraver. Here are some things to consider:

1. Purpose

The first thing you’ll want to think about is what you’ll be using the laser engraver for. As we mentioned before, laser engravers can be used for a variety of things. For example, you might want to use it for signage, branding, or product labels. Once you know what you’ll be using it for, you can narrow down your choices.

2. Metal Type You Want Engrave

You’ll also want to think about the type of metal you’ll be engraving. Some laser engravers are better suited for certain types of metal than others. For example, if you’re looking to engrave aluminum, you’ll want to choose a laser engraver that’s specifically designed for that.

3. Budget

Laser engravers can range in price from a few hundred dollars to several thousand dollars. So, you’ll want to have a budget in mind before you start shopping.

4. Engraving Size

You’ll also want to think about the dimensions of the metal you’ll be engraving. Some laser engravers are only able to accommodate small pieces of metal, while others can handle larger pieces.

5. Skill Level

If you’re new to laser engraving, you’ll want to choose a machine that’s relatively easy to use. On the other hand, if you have some experience with laser engraving, you might want to choose a more advanced machine.

What’s the Difference Between Laser Etching, Laser Engraving and Laser Marking?

When it comes to working with metal, there are three distinct methods of laser techniques that are commonly used – laser etching, laser engraving and laser marking.

Each method has unique advantages and disadvantages, and it is crucial to understand their differences to make the best choice for your project.

- Laser etching

Laser etching uses a laser beam to cut away material from the surface of the metal to create a design or pattern. The design is then burned into the surface of the metal, leaving an indelible impression. Laser etching is ideal for creating intricate designs and patterns and adding text or logos to items such as jewelry, coins, and tools.

- Laser engraving

Laser engraving works similarly to laser etching, but instead of cutting away material, a focused beam of light is used to burn marks or designs into the surface of the metal. This method is ideal for creating precise, detailed patterns and images on the surface of the metal and adding text and logos.

- Laser Marking

Lastly, laser marking implores light to heat up and alter the color of the metal. This method often creates permanent identification marks on components such as serial numbers and barcodes. Laser marking can also be used to add text and logos to items.

However, the results are less precise than those achieved by laser engraving.

Which Metals Can You Laser Engrave?

- Aluminum

Aluminium can be cut using a CO2 or fiber laser to create clean and detailed engravings. The laser exposes the bright aluminum beneath, which creates a high contrast with the black anodized aluminium.

This process is often used for creating custom business supplies, such as branded pens, flasks, and metal business cards. It can also be used for creating aesthetic body parts for automobiles.

- Titanium

Titanium can be marked, engraved, or etched. It is often used in jewelry, and services are available that use lasers to engrave names, dates, fingerprints, symbols, or other sentimental designs onto the jewelry. This process is called metal laser engraving. Fiber lasers can also be used to engrave titanium sheets for other purposes, such as creating metal signs for small businesses.

- Stainless Steel

With laser marking, high contrasts are possible, but laser engraving of stainless steel is also possible. The most frequent type of stainless steel is 316 or 306. Stainless steel is a popular metal for those on a budget and is used for aesthetic pieces like motorcycle components, furniture, railings, and vehicle suspensions. With a color laser marking machine, you can also create markings on stainless steel.

- Steel

Steel can be engraved using a laser, though the process is much more complex than other materials. In addition, the toughness of steel makes it hard to create enough contrast on the surface for an effective engraving. This necessitates longer engraving times. However, it is possible to sacrifice some of the color/contrast of the engraving to speed up the process. Generally, faster engraving speeds will create white marks, while slower speeds will result in black marks.

- Brass and Copper

Laser engraving on copper and brass is possible because of their low melting points and high thermal and electric conductivity. This makes them ideal for musical instruments, jewelry, tubing and pipes, plumbing, nuts and bolts, and many electronics.

- Gold and Silver

Laser engraving is popular for precious engraving metals like gold, platinum and silver. Jewelers often use laser engraving to add sentimental messages or QR codes to jewelry pieces. The amount of material lost during laser engraving is negligible, even on precious metals.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.