Buyer Guide

Tube Laser Cutting Machine Manufacturer

In the ever-evolving world of manufacturing, technological advancements have paved the way for remarkable innovations. Among these innovations, tube laser cutting machines have emerged as a game-changer, redefining the way we approach precision cutting and shaping of materials. These cutting-edge machines have unlocked new possibilities, allowing manufacturers to push the boundaries of what was once thought possible. In this guest post, we will delve into the world of tube laser cutting machines, exploring their working principles, applications, and the leading manufacturers driving this technological revolution.

Tube Laser Cutting Machine Manufacturer

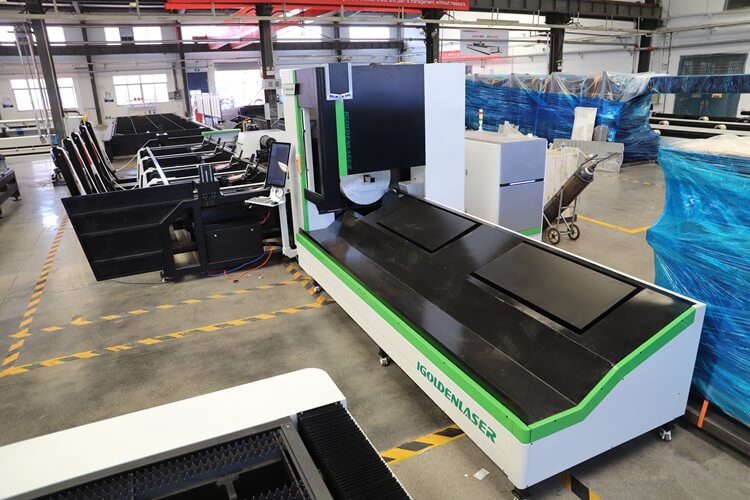

IGOLDEN Laser is a leading Chinese manufacturer of laser cutting machine specializing in fiber laser technology. The All-round tuber cutter stands out as the most versatile laser cutting machine in our product catalog. It features a solid-state laser source that enables the dynamic cutting of metal tubes and pipes. The pneumatic chuck provides full control of the material and zero tail material handling, making the process waste-free.

It comes in three models: iGR-T(B), iGR-T, and G22X-E, suitable for various industrial needs. The All-round tube cutters are available in power ratings ranging from 1500 to 6000 Watts. This machine can handle a wide range of thicknesses, from 0.8 to 10 mm, max. dia 220 mm and is compatible with almost all kinds of reflective and non-reflective metals.

All of the machine’s laser equipment is assembled using high-quality materials and cutting-edge technology. IGOLDEN Laser collaborates with world-leading industries such as IPG, Ospri, Motovario, and Yaskawa.

IGOLDEN Laser’s All-round tube cutting machine is equipped with smart software, enhancing precision, cutting speed, and the ability to handle complex designs with extraordinary accuracy. Additionally, the brand offers valuable services such as sample proofing, project evaluation, and warranties.

iGR-T(B) fiber Laser Tube Cutter

- Tube laser cutting machine is specially designed for metal tube cutting laser cutting machine. It can cut round tubes, square tubes, oval tubes, rectangular tubes and irregular tubes. It is equipped with a special cutting operating system, the system is simple to operate, high precision, professional and stable, suitable for professional profile cutting, widely used in sports equipment, oil pipelines, chemical equipment and other industries.

- Optional laser power 1000W-4000W; Optional countertop 6012/6016/6024; 3 meter tube and 6 meter tube are standard.

- Support customization

Laser Pipe Cutting Machine

Fiber Laser Metal Tube laser cutting machine is specially designed for laser cutting metal tubes, pipes, it is easy to operate. This fiber laser tube cutting machine improves cutting quality and cutting efficiency. The fiber laser cutter is widely used in sports equipment, various types of metal tubes & pipes, water pipes, oil pipelines and other industries.

ByTube can handle material thicknesses ranging from 10 to 15 mm and diameters up to 130 mm. It features an additional linear cutting head for increased speed and precision. The machine includes a Laserscan feature that compensates for tube bending, ensuring precise and accurate cuts. Also, it has a laser weld seam camera, which enhances cut quality, resulting in finer and mechanically sound cuts.

Tube Laser Cutting Machine iGR-T

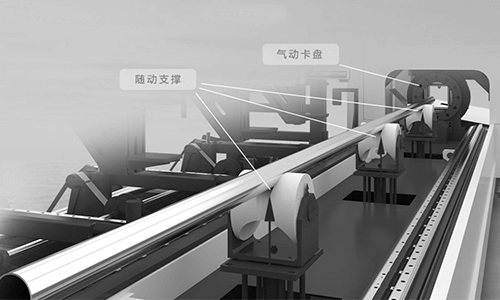

iGR-T series pipe fiber laser cutting machine is a kind of laser cutting equipment, designed for cutting various types of metal pipes with high precision and high speed, optional automatic feeding device, save labor, improve efficiency, tail blind area is small, save materials, using pneumatic chuck + follow support, efficient and stable, double insurance.

Suitable for a variety of pipe cutting, can cut round pipe, square pipe, rectangular pipe, hexagonal pipe, D-shaped pipe, other special-shaped pipe.

Widely used in auto parts, kitchen hardware, electronics, electrical, smart home and many other industries.

Automatic feeding device project and function introduction

- The automation unit has a good operating interface, and the connection mode is flexible, which is convenient for operators to use.

- The cutting machine feeding equipment is a laser pipe cutting machine feeding equipment and laser pipe cutting machine integrated system, mainly to achieve a centralized storage of a kind of pipe, instead of manual automatic feeding for laser pipe cutting machine, can achieve small batch, multi-variety production needs.

- Through PLC control, the whole process of automatic production such as automatic storage, automatic feeding and automatic feeding of a single pipe is realized, which can effectively guarantee product quality, improve production efficiency and reduce production costs. (Note: The material stack automatically lifts the pipe to the material delivery rack.

- The workers arrange the position of the whole bundle of pipes according to the positioning party.

Managed by the FSCUT-5000 control system, it offers a versatile and user-friendly operating experience. Lastly, It can deliver power between 3000 to 6000 Watts.

Why Choose IGOLDEN Laser Tube Cutters?

What sets IGOLDEN Laser’s all-around tube cutter apart is its extreme versatility, which can handle multiple machining processes. The power intensity can be configured between 1.5 kW to 6 kW, making it a highly adaptable option for various-sized manufacturing industries. It can handle numerous material types, such as aluminum, brass, copper, stainless steel, and carbon steel of varied thicknesses.

The machine’s work bed can process pipe lengths up to 6.5 meters and diameters up to 220 millimeters. In addition to providing high-quality machines, IGOLDEN Laser also offers remarkable value-added services such as extended warranties and training services.

Criteria for an Excellent Laser Tube Cutter

1. Power and Wattage The power of a laser cutter provides key insight into the capability and capacity of the machine. Typically, laser tube cutting machines are available in the range of 1500-6000 W. Contrarily, more isn’t always better. You need a proper feasibility report covering design complexity, material type, thickness, and compatibility to help you with power rating.

2. Laser Source Type The main laser sources available in tube cutting machines are CO2 laser and solid-state laser cutting systems. These days, fiber laser cutting machines, an upgrade to solid-state, offer high productivity, precision, and efficiency.

3. Material Compatibility Not all lasers are built the same. Different laser sources emit varying wavelengths of laser beam intensity, resulting in differences in compatibility with tube material types and thicknesses.

4. Bed Size and Work Area The bed size of a laser cutting machine provides vital information about the maximum dimensions of a workpiece the machine can handle efficiently. Having an optimal bed size is critical for efficient production.

5. Software and Control System A highly functioning cutting machine is nothing without its software. Ensure the manufacturer provides high-end laser cutting software capable of efficiently running the hardware. Also, it should be user-friendly.

6. Value Added Service A good laser tube cutting machine also provides convenient value-added services such as free machine training, repair services, and after-sales customer support.

Conclusion

We’ve curated a list of the most popular tube laser cutters on the market, including products from world-leading machine manufacturers. Before making a decision, we recommend thoroughly discussing your project requirements with your laser cutting machine manufacturer, as no two products are alike.

Our list of the top 10 laser tube cutting machines aims to significantly reduce your research time and assist you in purchasing the best product for your business.

Pingback: Anonymous