Buyer Guide

Laser Metal Cleaner: Solution for Rust, Paint, and Oxide Removal

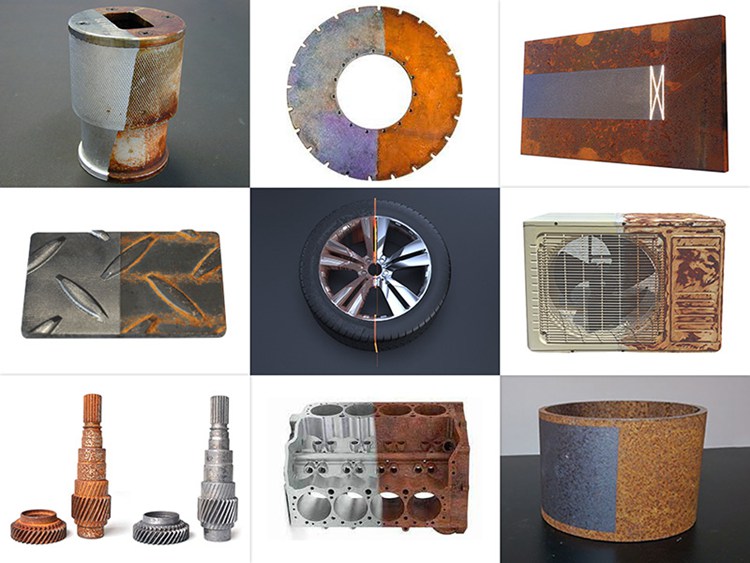

Laser metal cleaners represent revolutionary surface treatment technology that removes rust, paint, coatings, oxides, oils, and contaminants from metal surfaces using focused laser energy. Unlike traditional cleaning methods such as sandblasting, chemical stripping, or mechanical grinding, laser cleaning operates without abrasives, chemicals, or physical contact with the substrate, offering unprecedented precision, environmental benefits, and operational efficiency.

This comprehensive guide explores laser metal cleaning technology, compares different system types, examines applications across industries, provides power level selection guidance, analyzes costs and ROI, and offers best practices for successful implementation in metal fabrication, restoration, maintenance, and manufacturing operations.

Laser Metal Cleaner: Advanced Solution for Rust, Paint, and Oxide Removal

A laser metal cleaner is an advanced industrial cleaning system that uses high-energy laser beams to remove rust, paint, oxide layers, oil, and contaminants from metal surfaces. Compared with traditional cleaning methods such as sandblasting, chemical cleaning, or grinding, laser cleaning is non-contact, eco-friendly, and highly precise.

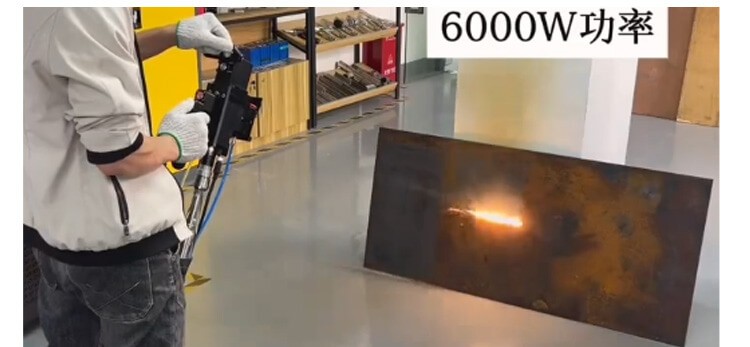

Pulse wave laser machines emit power 100W 200w,300w,500w,1000W. Continuous wave laser cleaning machines are much more powerful, with average output capabilities ranging from 1000w,2,000W , 3,000W,6000w .

Laser metal cleaning machines are widely used in manufacturing, automotive, aerospace, shipbuilding, mold maintenance, and metal fabrication industries.

Laser Rust Cleaner

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Understanding Laser Metal Cleaning Technology

How Laser Cleaning Works

Principle of Selective Ablation – Laser cleaning exploits the differential absorption of laser energy between contaminants and clean base metal:

- Energy Absorption: Rust, paint, oxides, and coatings absorb laser energy more readily than clean metal due to their different optical properties and lower ablation thresholds.

- Rapid Heating: Absorbed laser energy instantly heats the contaminant layer to its vaporization or sublimation temperature (typically occurring in nanoseconds).

- Material Removal: Rapid thermal expansion creates shock waves and plasma formation that explosively eject contaminants from the metal surface.

- Substrate Protection: Clean metal reflects most remaining laser energy, preventing damage once contaminants are removed. This self-limiting characteristic ensures safe cleaning.

Pulse vs. Continuous Wave:

- Pulsed Lasers (Most Common): Deliver energy in discrete pulses (nanosecond to picosecond duration) with high peak power, ideal for surface cleaning with minimal heat transfer to substrate.

- Continuous Wave Lasers: Less common for cleaning; primarily used in specialized applications requiring thermal processing.

System Configurations

Handheld Laser Cleaners – Most popular configuration:

Features:

- Portable cleaning head (typically 3-8 kg)

- Operator-controlled targeting and movement

- Real-time parameter adjustment

- Integrated safety sensors

- Suitable for irregular surfaces and field work

Advantages:

- Maximum flexibility

- Lower initial cost ($7,000-$20,000)

- Portable for on-site work

- Minimal setup requirements

Limitations:

- Operator-dependent consistency

- Lower throughput for large areas

- Operator fatigue on extended jobs

Robotic/Automated Laser Cleaners:

Features:

- Robot-mounted cleaning heads

- Programmed cleaning paths

- Vision systems for positioning

- High repeatability and consistency

Advantages:

- Consistent quality across production runs

- High throughput for repetitive tasks

- Minimal labor requirements

- Integration with production lines

Applications: Manufacturing environments with repetitive cleaning needs (weld seam cleaning, pre-coating preparation)

Investment: $30,000-$60,000+ including robot and integration.

Power Levels and Capabilities

50-100W Laser Metal Cleaners

Typical Specifications:

Power: 50-100W average

Cleaning width: 20-50mm

Cleaning speed: 1-3 m²/hour

Weight: 30-50 kg (backpack models available)

Applications: Light rust, thin coatings, precision cleaning

Ideal For:

- Small workshops and restoration shops

- Electronics manufacturing (circuit board cleaning)

- Jewelry and precious metal cleaning

- Mold maintenance (light deposits)

- Laboratory and research applications

Capabilities:

- Surface rust and flash rust removal

- Single layer paint removal

- Oil and grease removal

- Light oxide removal

- Precision cleaning of small parts

Limitations:

- Struggles with heavy rust or thick coatings

- Slow for large surface areas

- Limited production capacity

- Price Range: $8,000 – $20,000

100-200W Laser Metal Cleaners

Typical Specifications:

Power: 100-200W average

Cleaning width: 30-80mm

Cleaning speed: 2-6 m²/hour

Weight: 40-65 kg

Applications: General rust removal, moderate coatings

Ideal For:

- General metal fabrication shops

- Automotive restoration

- Maintenance and repair operations

- Monument and sculpture restoration

- Small to medium manufacturing

Capabilities:

- Light to moderate rust removal

- Multi-layer paint removal (2-4 layers)

- Oxide scale removal

- Weld seam cleaning

- Pre-coating surface preparation

- Price Range: $5,000 – $20,000

Best Value Proposition: Optimal balance of capability, portability, and cost for most small to medium operations

200-500W Laser Metal Cleaners

Typical Specifications:

Power: 200-500W average

Cleaning width: 50-120mm

Cleaning speed: 4-15 m²/hour

Weight: 60-100 kg

Applications: Heavy-duty industrial cleaning

Ideal For:

- Shipyards and marine maintenance

- Heavy equipment refurbishment

- Industrial surface preparation

- Bridge and infrastructure maintenance

- Large fabrication facilities

Capabilities:

Heavy rust and thick oxide removal

Thick paint and coating removal (5+ layers)

Large-scale surface preparation

Concrete cleaning and preparation

Graffiti removal from metal surfaces

Price Range: $30,000 – $60,000

Production Focused: Suitable for professional cleaning services and high-volume operations.

500-1000W+ Laser Metal Cleaners

Typical Specifications:

Power: 500-1000W+ average

Cleaning width: 80-150mm+

Cleaning speed: 10-30+ m²/hour

Weight: 80-150 kg+

Applications: Maximum-duty industrial applications

Ideal For:

Large shipbuilding operations

Nuclear decontamination

Major infrastructure projects

High-volume production cleaning

Industrial cleaning contractors

Capabilities:

- Any contamination level

- Extremely thick deposits and coatings

- Fastest cleaning speeds

- Automated production line integration

- Continuous heavy-duty operation

Price Range: $10,000 – $12,000+

Maximum Productivity: Lowest cost per square meter for high-volume applications

Applications and Use Cases

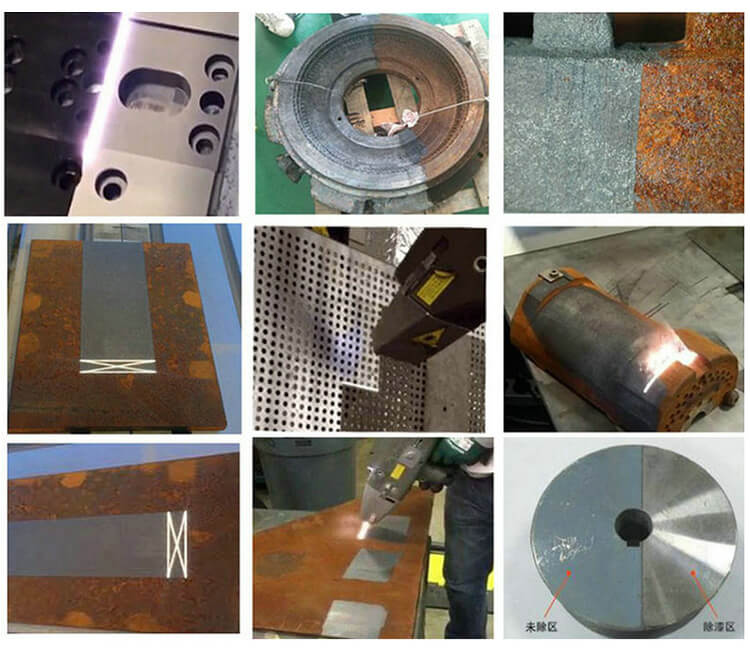

Rust Removal

Surface Rust – Light oxidation from atmospheric exposure:

- Typical cleaning speed: 5-15 m²/hour (200W system)

- Applications: Stored inventory, outdoor equipment, vehicle restoration

- Results: Returns metal to bare, clean condition

Moderate Rust – Established corrosion with visible pitting:

- Cleaning speed: 3-8 m²/hour (200-500W system)

- Applications: Used equipment, marine components, structural steel

- Results: Removes rust while preserving base metal

Heavy Rust and Scale – Thick corrosion layers and mill scale:

- Cleaning speed: 2-5 m²/hour (500W+ system)

- Applications: Shipbuilding, structural refurbishment, industrial equipment

- Results: Complete removal exposing clean metal for coating

Paint and Coating Removal

Single Layer Paint:

- Power required: 100-200W

- Speed: 4-10 m²/hour

- Applications: Touch-up areas, overspray removal

Multiple Layers (2-5 layers):

- Power required: 200-500W

- Speed: 3-7 m²/hour

- Applications: Vehicle restoration, equipment repainting

Heavy Industrial Coatings:

- Power required: 500W+

- Speed: 2-5 m²/hour

- Applications: Marine vessels, bridges, industrial structures

Selective Coating Removal: Laser parameters can be tuned to remove specific layers while preserving underlying coatings

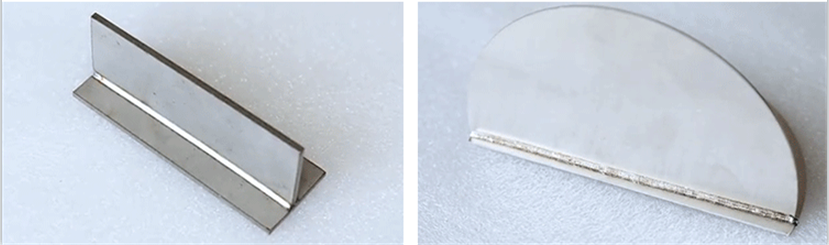

Weld Cleaning

Post-Weld Oxide Removal:

- Removes discoloration and oxidation from stainless steel, aluminum, and carbon steel welds

- Restores corrosion resistance

- Prepares surface for painting or plating

- Faster than pickling or mechanical methods

Pre-Weld Surface Preparation:

- Removes oils, oxides, and contaminants

- Improves weld quality and strength

- Reduces porosity and defects

- Critical for aluminum and stainless steel welding

Applications: Manufacturing, fabrication shops, shipbuilding, aerospace

Mold Cleaning

Injection Molds:

- Removes polymer residue, release agents, and carbon buildup

- No dimensional changes to mold surfaces

- Preserves complex geometries and fine details

- Faster than chemical cleaning or manual methods

Die Casting Molds:

- Removes aluminum oxide and metal buildup

- Extends mold life through gentle cleaning

- Reduces downtime versus bead blasting

Rubber and Tire Molds:

- Removes vulcanized rubber residues

- Maintains intricate tread patterns

- No mold wear or damage

Surface Preparation Before Coating

Paint Preparation:

- Creates optimal surface profile for coating adhesion

- Removes all contaminants and oxides

- Faster than grinding or sandblasting

- No abrasive embedding in surface

Powder Coating Preparation:

- Produces clean, oxide-free surface

- Improves coating adhesion and longevity

- Eliminates chemical pre-treatment steps

Plating Preparation:

- Critical for electroplating applications

- Ensures complete contaminant removal

- Improves plating adhesion and quality

Restoration and Conservation

Automotive Restoration:

- Classic car body panel cleaning

- Engine and mechanical component restoration

- Chrome and trim restoration

- Preserves original metal thickness

Cultural Heritage:

- Monument and statue cleaning

- Historical artifact restoration

- Architectural element conservation

- Gentle cleaning preserves patinas and details

Industrial Equipment Restoration:

- Machinery refurbishment

- Antique equipment restoration

- Railway and locomotive restoration

Specialty Applications

Concrete Surface Preparation:

- Removes laitance before coating or overlay

- Cleans reinforcing bar for repair

- Prepares joints for sealing

Graffiti Removal:

- Removes spray paint from metal surfaces

- No damage to underlying finish

- Works on stainless steel, aluminum, painted surfaces

Nuclear Decontamination:

- Removes radioactive contamination

- Minimal waste generation

- Remote operation capability

Composite Material Cleaning:

- Carbon fiber and fiberglass cleaning

- No mechanical damage to fibers

- Removes surface contamination before bonding

Why Choose a Laser Metal Cleaner

With increasing environmental regulations and demand for high-quality metal surfaces, laser metal cleaning has become the preferred solution for manufacturers worldwide. It improves productivity, reduces waste, and ensures consistent surface quality.

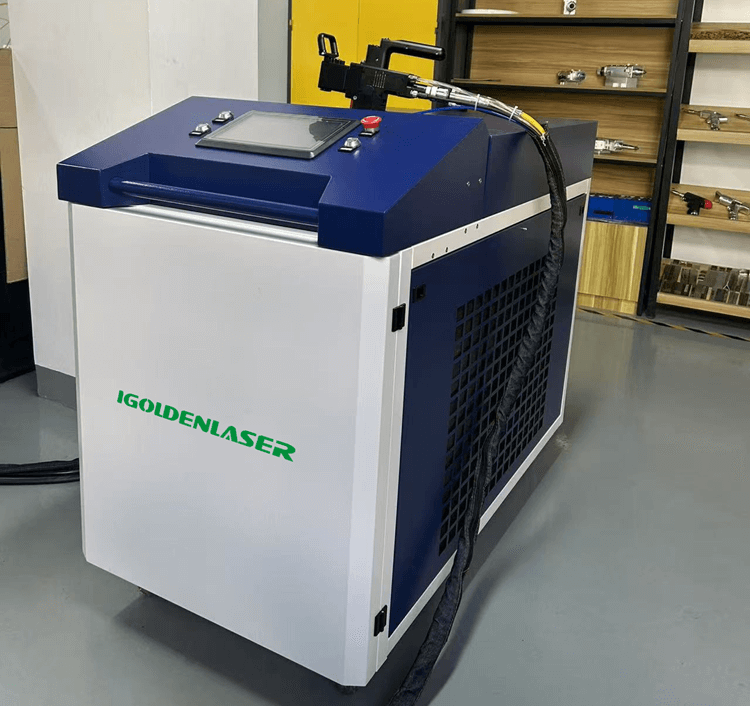

Manufacturers like iGOLDENCNC provide portable and automated laser metal cleaner solutions suitable for both small workshops and large industrial production lines.

Conclusion

Laser metal cleaners represent transformative technology for surface treatment, rust removal, paint stripping, and industrial cleaning applications. The combination of environmental benefits, operational efficiency, superior surface quality, and compelling economics makes laser cleaning increasingly the method of choice across industries from automotive restoration to aerospace manufacturing, from shipbuilding to cultural heritage conservation.

Selecting the appropriate laser metal cleaner requires careful analysis of application requirements, contamination types, production volumes, and budget parameters. Power levels from 50W entry systems to 1000W+ industrial machines ensure solutions for every need, from small restoration shops to large production facilities.

Understanding technology fundamentals, operational best practices, maintenance requirements, and safety protocols ensures successful implementation and maximum return on investment. As laser cleaning technology continues advancing through higher powers, AI integration, and enhanced automation, early adopters position themselves at the forefront of efficient, environmentally responsible metal surface treatment.

Whether removing rust from classic vehicles, preparing industrial equipment for coating, cleaning delicate historical artifacts, or stripping paint from ship hulls, laser metal cleaners deliver unmatched performance, efficiency, and quality in modern surface treatment operations.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.