Buyer Guide

Industrial Laser Welding Machine

In the dynamic world of modern manufacturing, the pursuit of precision, efficiency, and innovation has become a relentless driving force. Emerging as a game-changer in this evolving landscape, industrial laser welding machines have revolutionized the way businesses approach their fabrication challenges. These cutting-edge solutions are redefining the standards of manufacturing excellence, empowering organizations across a wide range of industries to unlock new levels of productivity, quality, and competitiveness.

Industrial Laser Welding Machine

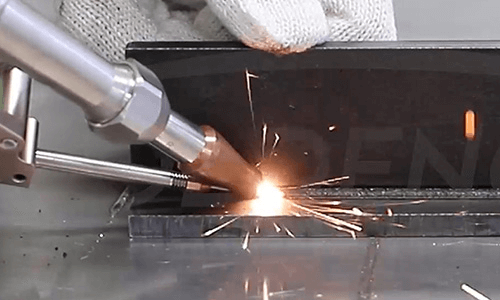

A Industrial laser welding machine is a high-precision, high-efficiency industrial tool used primarily to join steel products and thermoplastics. It uses a focused, high-energy laser beam as a heat source to thaw and fuse products through rapid cooling and heating, forming a solid, accurate weld in the joint. Compared to conventional welding processes, the laser welding innovation is highly regarded for its outstanding precision and excellent efficiency, especially in complicated frameworks or hard-to-reach locations.

The key advantage of laser welding equipment is its ability to produce deep, narrow welds without damaging the work surface. These machines are not only ideal for welding ultra-thin materials, but also for high-strength welds on thick plates. They are an essential tool for modern manufacturing to increase the quality and efficiency of production.

Industrial Laser Welding Machine Supplier

The Laser Welding Machine is a cutting-edge tool used to seamlessly weld metal parts with minimal environmental impact compared to traditional welding machines. The machine is used in jewelry manufacturing, kitchenware production, aerospace, automotive, electronics, commercial enterprises and shipbuilding. It is capable of spot, butt, lap, and T-butt welding, so it can handle complex, dense, and heat-sensitive parts. As a professional Laser Welding Machine manufacturer and supplier, our offerings include entry-level handheld laser welding equipment, industrial-grade laser welding equipment, and advanced 3D laser welding robots. With power ratings ranging from 1000W, 2000W and 3000W, we can meet the needs of machinists, operators, DIY enthusiasts, craftsmen, hobbyists, small business owners, commercial enterprises and industrial manufacturers. If one of these machines does not meet your needs due to type or price, please contact our sales team and we will customize it to fit your budget and needs.

Laser Cleaning Machine

Laser Welding Machine

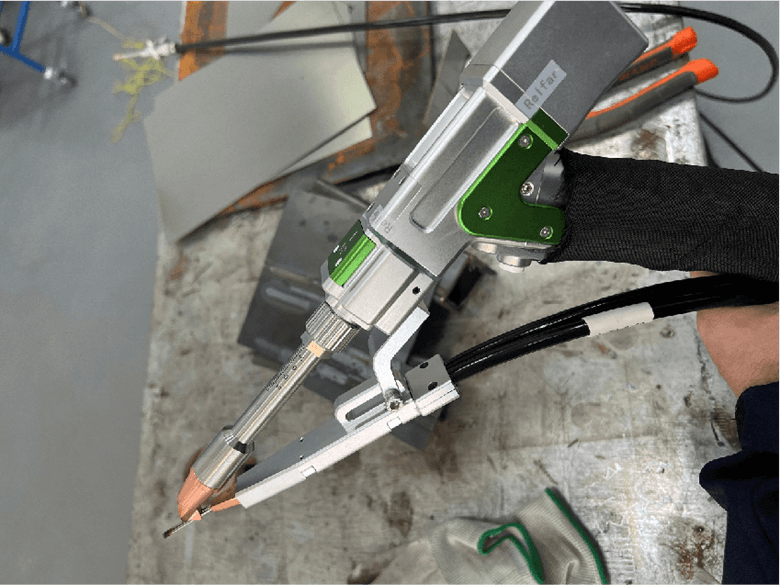

HandHeld Laser Welding Machine with Automatic Wire Feeder Device

Laser Welding Machine

Laser Welding Machine

Laser Welding Machine

Laser Welding Machine

Laser Welding Machine

Laser Cleaning Machine

Types & Applications of Industrial Laser Welding Machine

Laser welding machines can be classified according to their technological features, layout and application scenarios. The following is a detailed introduction to each type of laser welding machine, including its features and applications.

1. Handheld Laser Welding Machines

Overview: Portable laser welding machines are portable, lightweight and easy to use, and are designed for small and medium welding jobs that require a high degree of flexibility.

Application fields:

- Car repair: Can efficiently repair small parts such as car doors, exhaust pipes and frames.

- Jewelry manufacturing: Suitable for precise welding of precious metals such as gold, silver and platinum, and is widely used for repairs and personalization.

- House equipment: Like small repairs to stainless steel kitchen appliances.

- Hobbyist: Perfect for do-it-yourselfers and small workshops, with versatile operation and cost-effectiveness.

2. Automated Laser Welding Machine

Overview: Equipped with sophisticated automation system, the automated laser welding machine can significantly increase the productivity and consistency, which is one of the core equipment for commercial manufacturing.

Application areas:

- Medical equipment manufacturing: welding of surgical instruments, implants, and various other high-precision elements.

- Aerospace industry: such as generator blades, fuel tanks and various other complex structural parts of precision welding.

- Electronic industry: for circuit boards, sensors and other micro-components precision welding.

- Industrial parts production: equipment, valves and other high-strength steel parts of series production and welding.

3. Robotic Laser Welding Machine

Overview: Robot laser welding machine integrated with robotic arm innovation, made for large-scale, extremely repetitive industrial manufacturing jobs, can greatly increase the degree of automation of the production line.

Application areas:

- Automobile manufacturing: Welding of large parts such as car frames and chassis, especially suitable for assembly line processes.

- Heavy machinery: to assemble essential elements of commercial equipment such as tractors and cranes.

- Shipbuilding industry: for welding large steel plates and assembling ship components.

- Construction industry: efficient welding of steel beams, pipes and other building structural parts.

Main Features of Laser Welding Machines

High precision: Laser welding machines can achieve precise welding at the micron level, making them especially suitable for industries with high requirements for welding quality, such as aerospace, automotive manufacturing and the electronics industry.

High efficiency: Laser welding is significantly faster than traditional welding processes, greatly improving production efficiency and shortening manufacturing cycles.

Minimum heat-affected zone (HAZ): Laser welding has a very small heat input, effectively reducing thermal deformation of the material and maintaining the appearance and high quality of the product surface.

High compatibility: the laser welding machine supports welding of a variety of materials, including stainless steel, aluminum alloys, titanium alloys, and even able to weld dissimilar materials, which can meet different industrial needs.

Automation adaptability: laser welding machines can be easily integrated into automated production lines and used in conjunction with CNC systems, significantly improving the efficiency and stability of automated production.

Embracing the Future of Manufacturing with Industrial Laser Welding

By integrating industrial laser welding machines into your production environment, you can unlock a new era of productivity, quality, and competitiveness. This strategic investment empowers you to:

- Streamline your manufacturing processes and enhance overall throughput

- Achieve unparalleled precision and accuracy in your finished products

- Diversify your product offerings and cater to a wider range of customer needs

- Reduce material waste, energy consumption, and environmental impact

- Enhance workplace safety and improve operator satisfaction

How Industrial Laser Welding Machine Works?

The core operating principle of a laser welding machine is to use a concentrated high-energy laser beam of light to melt and fuse materials at the molecular level to produce a strong weld.

As a supplier of laser welding equipment, we recognize the value of every technological detail to improve our customers’ processes. The following is a comprehensive outline of how a laser welding machine works:

Laser Source

The heart of the laser welding machine is the laser source, which generates the high-energy laser beam. Common types of laser sources include solid-state lasers (e.g. YAG lasers), fiber lasers and CO₂ lasers.

- The laser beam is highly intense, monochromatic and directional, and can achieve extremely high energy concentration.

- Different laser sources can be selected according to the processing needs of customers to suit a variety of materials and applications.

Laser Beam Transmission

The laser beam is transmitted to the weld site through a collection of high-precision optical parts (such as lenses, mirrors, or optical fibers).

- The laser welding machine is integrated with a robotic arm or CNC (computer numerical control) control system to ensure that the laser beam can be precisely focused on the weld point.

- After focusing, the laser beam creates an area of extremely high energy thickness that can concentrate heat in a small area to achieve precise welding.

Absorption and Heating of Laser Energy

When the laser beam hits the material surface, the material absorbs the laser energy and rapidly heats up.

- The weld spot is heated to its melting factor in a short period of time, forming a molten weld pool.

- This very effective power conversion process ensures that the product melts in an extremely small heat-affected area, reducing damage to the adjacent product.

Fusion and Solidification of the Material

As the laser beam moves along the weld, the liquefied weld pool moves with it and solidifies rapidly after cooling.

- This process results in a homogeneous fusion of the weld products at the molecular level, producing a strong and aesthetically pleasing weld.

- The high accuracy of laser welding makes it ideal for applications where high weld quality is required.

Control System

Laser welders are equipped with an innovative control system that adapts the welding criteria to different processes.

- The control system precisely regulates key parameters such as laser power, welding speed and beam focus position, ensuring consistent and repeatable welding quality.

- For complex workpieces or non-standard welding requirements, individual customization can be achieved through programming.

Protective Measures

To ensure welding quality and prevent oxidation or contamination, a protective gas (such as argon, helium or nitrogen) is usually introduced during the welding process.

- The protective gas forms a barrier in the welding area to prevent the molten metal from contacting the air, thereby avoiding pores or impurities in the weld.

- Depending on the welding material, suppliers can offer a variety of shielding gas options to optimize the welding result.

Conclusion:

The rise of industrial laser welding machines has ushered in a transformative era for the manufacturing industry. By harnessing the power of this advanced technology, businesses can elevate their production capabilities, enhance their competitive edge, and position themselves as leaders in their respective fields. As the demand for cutting-edge, versatile manufacturing solutions continues to grow, the strategic adoption of industrial laser welding machines will be a crucial step towards unlocking your organization’s full potential and thriving in the dynamic landscape of modern production.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.