Laser Knowledge

How to Match Laser Power to Material Thickness

You can match laser power to material thickness by checking the type of metal and its thickness before you cut. For example, mild steel up to 25 mm often needs between 1.5 to 6 kW. Understanding both the maximum and minimum thickness your machine can cut helps you get clean, efficient results every time. The Metal Laser Cutting Guide gives you practical advice for every situation. See the table below for a quick reference on common metals:

| Material | Maximum Thickness (mm) | Recommended Power (kW) |

|---|---|---|

| Mild Steel | Up to 25 | 1.5 – 6 |

| Stainless Steel | Up to 20 | 1.5 – 4 |

| Aluminum | Up to 12 | 1.5 – 3 |

Key Takeaways

- Always match laser power to the thickness of the material for clean cuts and high quality.

- Use the Metal Laser Cutting Guide to find the right power settings for different metals.

- Adjust laser power based on material type: lower power for thin metals, higher for thick ones.

- Select the appropriate assist gas to improve cut quality and reduce oxidation.

- Regularly maintain your laser cutter to ensure consistent performance and avoid common cutting issues.

Why Laser Power Matters for Cutting Thickness

Cut Quality and Efficiency

When you select the right laser power for your material thickness, you improve both the quality and efficiency of your cutting process. Laser cutting relies on the precise application of energy to melt or vaporize metal. If you use too little or too much laser power, you risk poor results.

- Thin materials, such as sheets under 2 mm, require only 100–500W for effective cutting.

- Medium thicknesses, from 2 to 10 mm, usually need 1–3 kW.

- For thick metals above 10 mm, you often need 4 kW or more to achieve clean cuts.

Matching laser power to the thickness ensures you get smooth edges and minimal waste. You also reduce the need for secondary finishing. Higher power levels can increase cutting speed and allow you to handle thicker materials. Recent advancements in fiber laser technology, such as 12kW and 20kW systems, have made it possible to cut thicker metals faster and with better quality. These improvements help you boost productivity and maintain high standards in your work.

Tip: Using the correct assist gas, like nitrogen or oxygen, can further enhance cut quality and prevent oxidation during laser cutting.

Risks of Incorrect Laser Power

Incorrect laser power settings can cause several problems during cutting. If you use too much power, you may see burnt edges, excessive heat, and dross buildup. If you use too little, the laser may not cut through the material, leaving rough or incomplete edges.

Here are some common issues you might face:

- Burnt cutting edges from too much heat.

- Severe burrs and slag formation when laser power is too high.

- Incomplete cuts and poor edge quality if power is too low.

During laser cutting, improper power can also lead to heat accumulation at the cut edge. This may result in uneven surfaces or even ablation. You want to avoid these defects because they lower the overall quality of your finished parts and can waste both time and material. By carefully matching laser power to your material thickness, you protect your equipment and ensure consistent, high-quality results.

Maximum and Minimum Cutting Thickness by Laser Power

Understanding the maximum and minimum cutting thickness for each laser type helps you choose the right equipment and settings for your project. The relationship between laser power and cutting thickness is direct but not always linear. As you increase laser power, you can cut thicker metals, but the speed and quality gains decrease at higher levels. You need to consider both the maximum and minimum cutting thickness for each laser type to achieve the best results.

Fiber Laser Cutting Capacities

Fiber lasers have become the top choice for many metal fabrication shops. You can use fiber laser power to cut a wide range of metals, including steel, stainless steel, and aluminum. The maximum cutting thickness depends on the fiber laser power you select. For example, a 1.5 kW fiber laser can cut up to 6 mm of steel, while a 40 kW system can handle up to 50 mm. The table below shows how fiber laser power affects the maximum cutting thickness for common metals:

| Power Level | Material | Stable Production Thickness | Absolute Maximum |

|---|---|---|---|

| 1–2 kW | Carbon steel | 4–6 mm | ~10 mm |

| Stainless steel | 2–4 mm | ~6 mm | |

| Aluminum | 1.5–3 mm | ~4 mm | |

| 3–4 kW | Carbon steel | 8–12 mm | ~20 mm |

| Stainless steel | 6–8 mm | ~12 mm | |

| Aluminum | 4–6 mm | ~8 mm | |

| 6 kW | Carbon steel | 15–20 mm | ~25 mm |

| Stainless steel | 10–15 mm | ~20 mm | |

| Aluminum | 8–10 mm | ~12 mm | |

| 8–12 kW | Carbon steel | 20–30 mm | ~40 mm |

| Stainless steel | 15–25 mm | ~30 mm | |

| Aluminum | 10–15 mm | ~18 mm |

You can see that increasing fiber laser power allows you to cut thicker steel and other metals. However, the gains in speed and quality become smaller as you reach higher power levels. For example, doubling fiber laser power for thin steel (1–3 mm) can increase speed by up to 80%. For thick steel (15 mm or more), doubling power may only boost speed by 20–30%. This shows the diminishing returns at higher power levels.

The minimum cutting thickness for fiber lasers is also important. You should not use high fiber laser power on very thin metals, as this can cause burning or warping. For thin sheets under 1 mm, you can use lower power settings, such as 100–500 W, to achieve clean cuts.

CO₂ and Nd:YAG Laser Cutting Capacities

CO₂ lasers and Nd:YAG lasers offer different maximum cutting thickness values compared to fiber lasers. You can use CO₂ lasers for a variety of metals, but their maximum cutting thickness is usually less than fiber lasers at the same power level. Nd:YAG lasers are best for high-precision work on thin metals.

| Laser Type | Maximum Cutting Thickness |

|---|---|

| Fiber Lasers | Up to 25 mm |

| CO₂ Lasers | Up to 20 mm |

| Nd:YAG Lasers | Up to 10 mm |

For example, a 3 kW CO₂ laser can cut up to 12 mm of steel, while a 6 kW CO₂ laser can reach 20 mm. Nd:YAG lasers, with their high precision, are ideal for electronics and jewelry, but their maximum cutting thickness is limited to about 10 mm for steel.

Note: Always check the manufacturer’s recommendations for maximum and minimum cutting thickness. The Metal Laser Cutting Guide provides detailed charts for each laser type and power level.

Factors Affecting Cutting Thickness

Several factors influence the maximum cutting thickness you can achieve with a given laser power. These include assist gas type, focus position, material surface condition, and environmental factors.

- Assist Gas: The type of assist gas you use affects both cutting speed and edge quality. Oxygen allows you to cut thicker steel at lower laser power due to its exothermic reaction, but it can leave oxide layers. Nitrogen produces clean edges but may require higher laser power for thick metals. Compressed air is suitable for thin metals and offers moderate quality at a lower cost.

| Assist Gas | Material Thickness | Cutting Speed | Edge Quality | Cost |

|---|---|---|---|---|

| Compressed Air | Up to ~6 mm | Moderate | Moderate | Low |

| Oxygen | 6 mm and above | High | Rough | Moderate |

| Nitrogen | Thin and thick | Moderate | Clean | High |

- Focus Position: You need to adjust the focus position based on material type, thickness, and assist gas. The optimal focus is not fixed. Changing materials or thickness means you must reset the focus, even if laser power stays the same.

- Material Surface Condition: Clean, rust-free surfaces allow for better energy absorption and more consistent cutting thickness. Dirty or coated metals may require higher laser power to achieve the same maximum cutting thickness.

- Environmental Factors: High ambient temperature can reduce cooling efficiency, leading to overheating. High humidity can cause condensation, which affects both electrical components and laser beam quality. These conditions can lower the maximum cutting thickness and reduce cut quality.

- Industry Recommendations: Most manufacturers agree that you should select a laser cutter with enough power for your current and future needs. For example, 1500 W handles up to 10 mm steel, 3000 W is good for up to 20 mm, and 6000 W can cut up to 30 mm.

| Power Rating | Maximum Thickness | Ideal Applications |

|---|---|---|

| 1500W | Up to 10mm | Light industrial use |

| 3000W | Up to 20mm | Medium production |

| 6000W | Up to 30mm | Heavy industrial use |

You can use the Metal Laser Cutting Guide to find the recommended laser power for your specific metal and thickness. This helps you avoid common problems and achieve the highest quality cuts.

How to Select the Right Laser Cutting Power

Choosing the right laser cutting power for your project ensures you achieve clean cuts, high edge quality, and efficient production. You need to consider several factors, including material type and thickness, your desired edge quality, and the capabilities and costs of your machine. Follow these steps to match laser cutting power to your needs.

Assess Material Type and Thickness

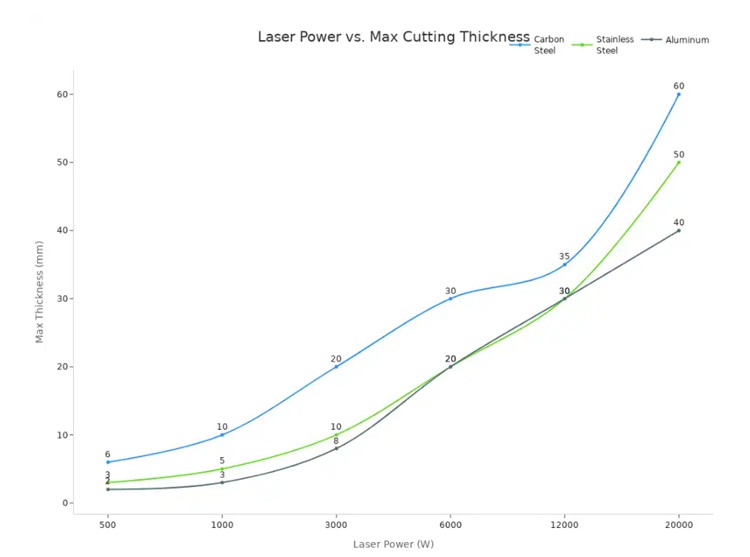

Start by identifying the material you want to cut. Each metal reacts differently to laser energy. For example, carbon steel, stainless steel, and aluminum all require different laser power levels for optimal results. You also need to measure the material thickness. This step is crucial because thin materials and thick materials respond differently to the same laser cutting power.

Use the table below to match laser power to common metals and their thicknesses:

| Laser Power (W) | Carbon Steel (mm) | Stainless Steel (mm) | Aluminum (mm) |

|---|---|---|---|

| 500 | Up to 6 | Up to 3 | Up to 2 |

| 1000 | Up to 10 | Up to 5 | Up to 3 |

| 3000 | Up to 20 | Up to 10 | Up to 8 |

| 6000 | Up to 30 | Up to 20 | Up to 20 |

| 12000 | Up to 35 | Up to 30 | Up to 30 |

| 20000 | Up to 60 | Up to 50 | Up to 40 |

You can see that higher laser cutting power lets you cut thicker metals. For thin materials, you should use lower power to avoid burning or warping. When cutting thick materials, you need more power to maintain speed and edge quality.

Determine Desired Edge Quality

Think about the edge quality you want for your finished parts. High edge quality means smooth, clean edges with little to no burrs. If you need perfect edges for visible parts or tight-fitting assemblies, you must adjust your laser cutting power and settings carefully.

Here are some factors that affect edge quality:

- Laser cutting power: Too much power can cause burnt edges, while too little leaves rough or incomplete cuts.

- Cutting speed: Slower speeds can improve edge quality but may cause heat buildup on thick materials.

- Focus and lens quality: A well-focused beam produces cleaner edges, especially on thin materials.

- Assist gas type and pressure: Nitrogen gives you clean, oxide-free edges. Oxygen works well for cutting thick materials but may leave oxide layers.

If you work with thin materials, use lower laser cutting power and a fast cutting speed to prevent overheating. For cutting metals like stainless steel or aluminum, you may need to fine-tune your settings to achieve the best edge quality. Always run test cuts and inspect the edges before starting full production.

Note: The guide suggests starting with recommended settings, then adjusting power and speed in small steps to reach your desired edge quality.

Consider Machine Capabilities and Costs

You should always check your machine’s maximum and minimum laser cutting power. Not all machines can handle every material thickness or type. Review your equipment’s specifications and compare them with your project requirements.

When you use higher laser cutting power, you can cut thick materials faster and reduce overall costs. This efficiency comes from shorter cutting times and fewer passes. Lower power lasers may seem less expensive, but they increase operational costs due to slower speeds and the need for more skilled operators. High-power machines also give you a wider process window, which reduces scrap and improves consistency.

Here’s a simple checklist to help you decide:

- Check your machine’s rated laser cutting power.

- Match your material type and thickness to the recommended power range.

- Consider the cost of running your machine at higher power versus lower power.

- Factor in the need for high edge quality and the cost of secondary finishing.

- Use the Metal Laser Cutting Guide for tailored recommendations.

Tip: For most shops, investing in a machine with higher laser cutting power pays off when you regularly cut thick materials or need high productivity.

Step-by-Step Guide for Matching Laser Cutting Power

- Identify your material type and measure its thickness.

- Refer to the recommended laser cutting power for your material and thickness.

- Set your machine to the suggested power level.

- Choose the right assist gas for your material and desired edge quality.

- Adjust focus and cutting speed for thin materials or thick materials as needed.

- Run a test cut and inspect the edge quality.

- Fine-tune your settings based on the results.

Practical Tips for Optimizing and Troubleshooting

- For thin materials, always start with lower laser cutting power and increase only if needed.

- Use nitrogen for clean edges on stainless steel and aluminum.

- If you see burnt edges, reduce power or increase speed.

- For incomplete cuts, increase laser power or slow down the cutting speed.

- Clean your lens and check focus regularly to maintain high edge quality.

- Keep your material surface clean to avoid inconsistent results.

Remember: Consistent monitoring and small adjustments help you achieve the best edge quality and extend your machine’s life.

By following these steps and tips, you can select the right laser cutting power for any project. The Metal Laser Cutting Guide remains your best resource for detailed recommendations and troubleshooting advice.

Optimizing Laser Cutting for Best Results

Adjusting Power for Speed and Quality

You can achieve the best cutting quality by carefully adjusting laser power, speed, and other settings. Precision matters at every step. When you work with thin metals, lower laser power often produces cleaner edges. Thicker materials require higher power, but you must balance this with speed to avoid excessive heat. High power for cleaner edges works well for demanding jobs, but you should always test settings before full production.

Consider these practical tips for optimizing your laser cutting process:

- Adjust frequency settings to improve edge smoothness. Higher frequencies enhance cutting quality but may slow down the process.

- Align the laser’s focal point with precision. Proper focus maximizes energy delivery and boosts cutting quality.

- Select the right assist gas and pressure. Nitrogen works best for non-ferrous metals, while oxygen suits ferrous metals. High purity gases increase efficiency and precision.

- Conduct test cuts on sample materials. This helps you find the ideal balance between speed and cutting quality.

- Remember that changes in one parameter affect others. Make adjustments thoughtfully to maintain precision.

- Always follow manufacturer guidelines for specific materials and thicknesses.

- Maintain your high wattage laser system regularly. Clean optics and lenses to ensure consistent precision and cutting quality.

Cutting thicker metals, such as 5052 aluminum above 0.25 inches, may result in a coarse finish. You need to adjust laser power and speed for optimal results. Automation and smart sensors can help you match laser power to material thickness with greater precision, improving productivity and cutting quality.

Tip: Use high power laser settings for thick materials, but monitor energy consumption to maintain efficiency.

Troubleshooting Common Laser Cutting Issues

You may encounter several issues during laser cutting. Precision in setup and operation helps you resolve most problems quickly. The following table outlines common issues, causes, and solutions:

| Issue | Cause | Solution |

|---|---|---|

| Burned or Charred Edges | High power or slow speed | Reduce laser power or increase speed |

| Jagged Edges | Misaligned beam or dirty nozzle | Realign beam and clean nozzle |

| Oxidized Edges | Oxygen assist gas | Switch to nitrogen for oxide-free cuts |

| Too Thin Material | Excess laser power | Lower laser power settings |

| Too Thick Material | Insufficient cutting depth | Increase laser power or adjust speed |

You should inspect materials for uniform thickness and use clamps for stability. Regular maintenance of your high wattage laser ensures consistent precision and cutting quality. Check mirror alignment weekly and calibrate your laser cutter using test cuts. Monitor the cutting process in real time and adjust settings as needed. Comprehensive training for operators reduces errors and improves cutting quality.

Note: Never leave a high power laser unattended. Always keep a fire extinguisher nearby and follow safety protocols to protect yourself and your equipment.

To match laser power to material thickness, follow these steps:

- Determine the thickness of your material.

- Select the right laser power for the metal type and thickness.

- Consider the material’s properties and your production needs.

- Evaluate efficiency and budget before choosing equipment.

You should always reference the IGOLDENLASER Metal Laser Cutting Guide for the latest recommendations. This resource helps you stay updated with new technology and ensures precise results.

| Maintenance Task | Frequency | Best Practice |

|---|---|---|

| Inspect laser optics | Monthly | Clean and align for best performance |

| Check cooling system | Quarterly | Look for leaks and blockages |

| Review safety gear | Bi-weekly | Ensure fire extinguishers are ready |

FAQ

What happens if you use too much laser power for thin metal?

You risk burning, warping, or melting the material. Always start with lower power for thin sheets. Test on scrap pieces before full production.

How do you know which assist gas to use?

Nitrogen gives you clean, oxide-free edges. Oxygen works best for thick steel but may leave oxide. Compressed air is cost-effective for thin metals.

Can one laser cutter handle all metal thicknesses?

No. Each machine has a power range and thickness limits. Check your machine’s specifications and use the Metal Laser Cutting Guide for recommendations.

Why does edge quality change with different settings?

Laser power, speed, focus, and assist gas all affect edge quality. Small adjustments can make a big difference. Always inspect your cuts and adjust as needed.

Is higher laser power always better?

Not always. High power cuts thick materials faster, but can damage thin metals. Choose power based on your material and thickness for the best results.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.