Buyer Guide, Laser Knowledge

How to Clean Rust off Metal | the Best Way Is Recommended

How to Clean Rust off Metal by Laser Machine

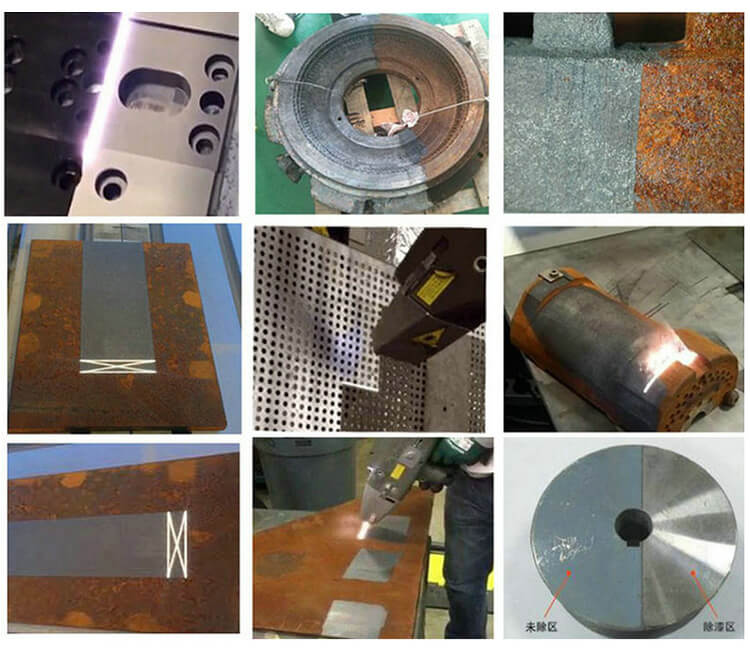

Cleaning rust off metal using a laser is a modern, efficient, and environmentally friendly method known as laser rust removal or laser cleaning.

No water or solvent is required, and the waste is easy to collect and does not pollute the environment. Safe and reliable, does not damage the health of operators. Wide range of applications for removing rust, scale, dirt and coatings of various thicknesses and compositions. The cleaning process is easy to automate, realize long-distance remote control operation, and can be used for large-scale laser rust removal work.

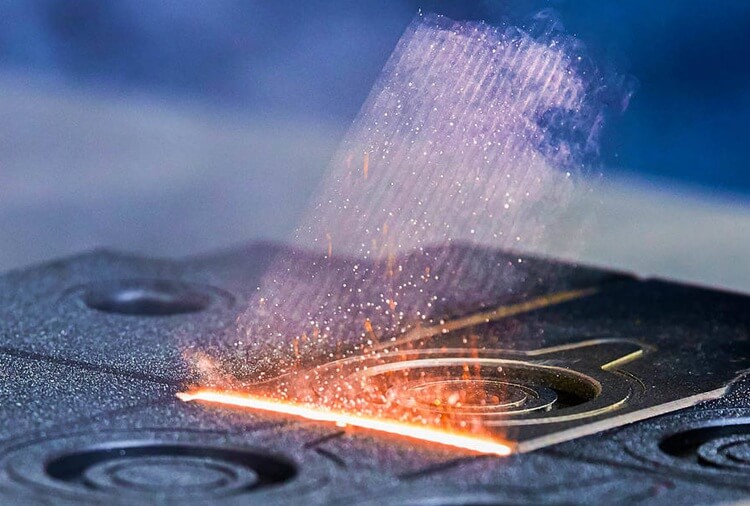

Laser rust removal works by directing a high-intensity laser beam onto the rusted surface.The laser energy is absorbed by the rust, causing it to heat up rapidly and vaporize. As the rust evaporates, it is effectively removed from the metal surface, leaving behind a clean and restored area. The laser can be precisely controlled to target only the rusted areas, minimizing the risk of damage to the surrounding metal.

The energy of a focused laser beam is used to ablate – break molecular bonds and vaporize – unwanted material, be it contaminants or coatings on a surface. The technology can effectively remove corrosion, residue, paint, and other substances without damaging the underlying substrate.

This process is non-contact, controlled, and precise, allowing for the selective removal of unwanted layers.

Laser cleaning is becoming more widely adopted in various industries due to its precision, efficiency, eco-friendliness, and the minimal damage it causes to the surface being cleaned.

Here is IGOLDENLASER collection of the most popular laser cleaning machines for every need and budget in 2025, including automatic, portable and handheld series, as well as backpack and trolley types. IGOLDENLASER‘s laser cleaning systems come with different power options including pulsed fiber laser powers of 50W, 100W, 200W, 300W and 500W, as well as CW fiber laser powers of 1000W, 1500W, 2000W and 3000W to match your surface treatment needs and budget. No matter what you’re going to do, always one option fits for you.

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Unravel the Power of Laser Cleaning for Rust Removal

Laser cleaning technology harnesses the focused energy of a high-intensity laser beam to remove rust, scale, and other contaminants from metal surfaces without causing any damage to the underlying material. This revolutionary process offers a multitude of benefits that make it a game-changer in the world of industrial cleaning and restoration.

- Precise and Controlled Removal: The laser beam can be precisely targeted and controlled, allowing for the selective removal of rust and other surface impurities without compromising the integrity of the metal. This level of precision ensures that only the unwanted material is removed, leaving the base metal unaffected.

- Environmentally Friendly and Safe: Laser cleaning is a dry, non-abrasive process that does not generate any harmful waste or byproducts. This eco-friendly approach eliminates the need for hazardous chemicals or disposal methods, making it a safer alternative for your workforce and the environment.

- Versatility in Surface Preparation: In addition to rust removal, laser cleaning can be used to prepare a wide range of metal surfaces for subsequent coatings, painting, or other finishing processes. The clean, uniform surface finish achieved through laser cleaning can significantly improve the adhesion and durability of these secondary treatments.

- Improved Efficiency and Productivity: Laser cleaning is a highly automated process that can be integrated into your existing workflows, dramatically reducing the time and labor required for rust removal tasks. This increased efficiency translates to cost savings and enhanced overall productivity.

- Consistent and Repeatable Results: The laser cleaning process is inherently consistent, with each application delivering the same level of quality and finish. This consistency ensures that your metal surfaces are restored to a uniform, pristine condition, time after time.

Common Laser Types for Rust Removal:

| Laser Type | Ideal For |

|---|---|

| Fiber Laser | Metal surfaces, high precision |

| Pulsed Laser | Rust, paint, oxides, and coatings |

| Continuous Wave | Deep cleaning, fast removal |

Laser Rust Removal Use Cases

| Industry | Application |

|---|---|

| Automotive | Frame restoration, part cleaning |

| Shipbuilding | Hull and deck rust removal |

| Manufacturing | Mold and tool maintenance |

| Aerospace | Oxide removal on aluminum or titanium |

| Heritage/Art | Gentle cleaning of historical artifacts |

Elevate Your Metal Restoration with Laser Cleaning

By integrating laser cleaning technology into your rust removal processes, you can unlock a new era of efficiency, safety, and surface quality. This strategic investment empowers you to:

- Effortlessly remove rust and other contaminants from metal surfaces without damaging the underlying material.

- Prepare metal surfaces for subsequent coatings, paint, or finishing processes with consistent, high-quality results.

- Enhance your environmental sustainability and reduce your exposure to hazardous chemicals.

- Streamline your workflow and improve overall productivity through automated, efficient cleaning processes.

- Safeguard your workforce and comply with industry regulations through the use of a safe, non-abrasive cleaning method.

Conclusion

Laser cleaning technology has emerged as a transformative solution for the removal of rust and other surface impurities from metal surfaces. By harnessing the power of this advanced approach, you can elevate your metal restoration and surface preparation capabilities, delivering consistent, high-quality results while prioritizing safety and environmental sustainability. As the demand for efficient, eco-friendly cleaning solutions continues to grow, the strategic adoption of laser cleaning will be a crucial step towards unlocking your organization’s full potential and solidifying your position as an industry leader in metal revitalization.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.