Buyer Guide

Honeycomb Board & Corrugated Board CNC Cutting Machine

In today’s fast-growing industries of packaging, furniture, advertising, and construction, honeycomb board and corrugated board have become indispensable materials due to their lightweight, eco-friendly, and cost-effective properties. However, these materials present unique challenges in cutting and processing. Traditional die-cutting methods often require expensive molds, lack flexibility, and increase production costs. This is where the Honeycomb Board & Corrugated Board CNC Cutting Machine comes into play, offering a digital, mold-free, precise, and efficient solution.

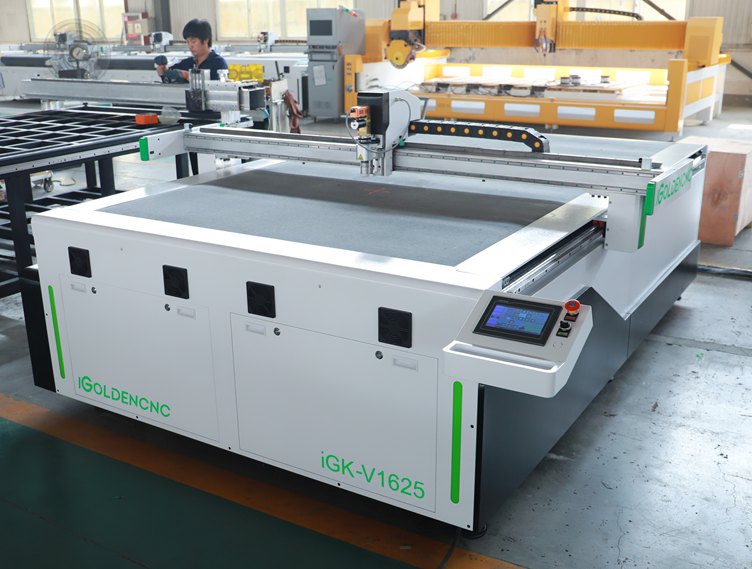

As a leading CNC equipment manufacturer, IGOLDENCNC provides high-performance digital cutting solutions tailored to handle honeycomb and corrugated boards with precision and versatility.

Honeycomb Board & Corrugated Board CNC Oscillating Knife Cutting Machine

A CNC oscillating knife cutting machine is a precision manufacturing system specifically designed to cut honeycomb board and corrugated board materials with exceptional accuracy and clean edges. Unlike traditional die-cutting methods, these machines use computer-controlled oscillating knife technology that vibrates at high frequencies while moving through the material, creating smooth, precise cuts without crushing or delaminating the board structure.

The oscillating knife cutting technology is particularly suited for honeycomb and corrugated materials because it maintains the structural integrity of the cellular core while delivering clean, precise cuts that traditional rotary cutters cannot achieve. This makes it the preferred choice for packaging manufacturers, display producers, and industrial applications requiring high-quality board processing.

Understanding Honeycomb Board and Corrugated Board Materials

Honeycomb Board Characteristics

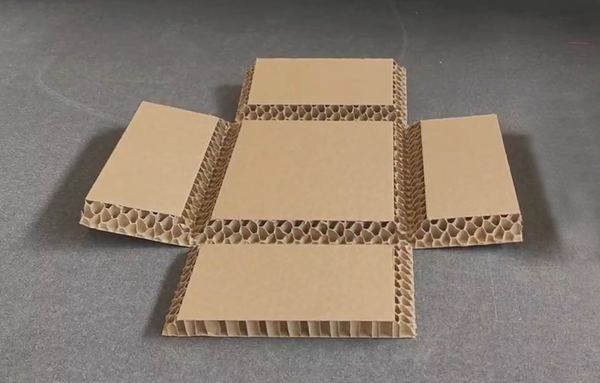

Honeycomb board consists of a hexagonal cell core structure sandwiched between flat face sheets, creating an incredibly strong yet lightweight material. The cellular structure provides excellent strength-to-weight ratios, making it ideal for protective packaging, automotive components, aerospace applications, and architectural panels. However, this structure requires specialized cutting techniques to prevent core collapse and edge fraying.

Corrugated Board Properties

Corrugated board features a fluted corrugated sheet bonded between flat linerboards, available in single-face, single-wall, double-wall, and triple-wall configurations. The corrugated structure provides cushioning properties and structural strength while remaining cost-effective for packaging applications. Different flute sizes (A, B, C, E, F) offer varying characteristics for specific applications.

Tool Options and Cutting Capabilities

Oscillating Knife Tools

- Standard Blades: General-purpose cutting for most corrugated and honeycomb materials

- Deep Cut Blades: Extended length for thick honeycomb boards up to 50mm

- Specialty Blades: Custom geometries for specific material combinations

- Carbide Tools: Extended life for high-volume production applications

Processing Tools

- Creasing Wheels: Create fold lines in corrugated materials without cutting through

- Perforating Tools: Generate tear lines and ventilation patterns

- V-Cut Tools: Produce beveled edges for folding applications

- Kiss-Cut Blades: Surface cutting for adhesive materials and labels

Multi-Tool Capabilities

Advanced systems accommodate multiple tools simultaneously, enabling complex processing operations in a single pass. Automatic tool changers reduce setup time and increase productivity by eliminating manual intervention between operations.

Applications Across Industries

Packaging Manufacturing

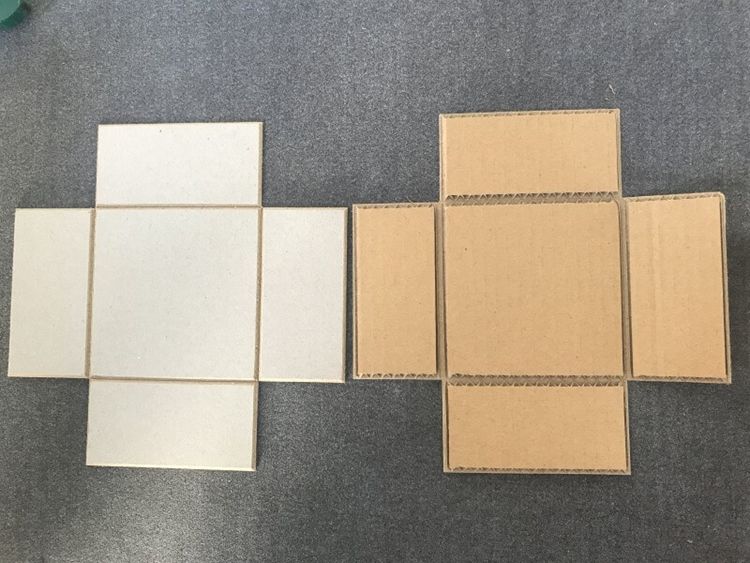

Corrugated box manufacturers use CNC oscillating knife cutters for prototype development, short-run production, and custom packaging solutions. The ability to quickly produce samples and test designs accelerates product development and customer approval processes.

Display and Point-of-Purchase

Retail display manufacturers rely on precise cutting for complex assemblies, promotional displays, and temporary installations. The clean edges and accurate dimensions ensure professional appearance and reliable assembly.

Automotive Industry

Honeycomb panels used in automotive applications require precise cutting for components like floor panels, trunk liners, and sound insulation. The structural integrity maintained by oscillating knife cutting is crucial for these applications.

Aerospace Applications

Aircraft interior panels, cargo liners, and structural components made from honeycomb materials demand the highest cutting quality. CNC oscillating knife systems meet the stringent requirements for edge sealing and dimensional accuracy.

Industrial Packaging

Heavy-duty packaging for industrial equipment and machinery requires precise fitting and maximum protection. Custom honeycomb inserts and corrugated structures provide optimal product protection while minimizing packaging volume.

Why CNC Cutting for Honeycomb & Corrugated Boards?

Traditional die cutting is costly and inflexible. CNC cutting solves these problems by:

- Mold-Free Cutting → Reduce setup costs, especially for prototypes and small batches.

- High Precision → Ensures smooth, accurate edges without material deformation.

- Flexibility → Supports multiple materials and thickness levels.

- Efficiency → Automates creasing, cutting, and V-grooving in one process.

- Eco-Friendly → Cuts without burning or chemical processing.

Selection Criteria for CNC Oscillating Knife Systems

Production Volume Assessment

High-volume operations benefit from faster cutting speeds, automatic material handling, and multi-shift operation capabilities. Lower volume users may prioritize versatility and ease of operation over maximum speed.

Material Range Requirements

Consider the full range of materials you’ll process, including current and future requirements. Ensure the system accommodates your thickest materials with appropriate cutting depth and power.

Precision Demands

Applications requiring tight tolerances need systems with high-accuracy linear drives, thermal compensation, and stable mechanical construction. Consider both cutting accuracy and edge quality requirements.

Integration Needs

Modern systems offer integration with CAD software, production planning systems, and quality control equipment. Evaluate how the cutting system will integrate with your existing workflow and software tools.

Space and Infrastructure

Assess available floor space, power requirements, and compressed air capacity. Some systems require specialized ventilation for dust extraction and operator comfort.

Conclusion

The demand for eco-friendly, lightweight, and versatile materials like honeycomb board and corrugated board continues to rise across packaging, furniture, advertising, and construction industries. Traditional cutting methods are no longer efficient or cost-effective. The Honeycomb Board & Corrugated Board CNC Cutting Machine by IGOLDENCNC provides the ultimate solution: high precision, flexibility, and productivity without molds.

Whether you are a packaging factory, a furniture manufacturer, or an advertising agency, IGOLDENCNC has the right CNC cutting solution to meet your needs. Contact us today to discuss how we can help your business achieve smarter, faster, and more profitable production.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.