Buyer Guide

Handheld Metal Laser Welding and Cutting Machine

A handheld metal laser welding and cutting machine is a portable device used for joining and cutting metal components using laser technology. These machines typically use high-powered lasers to melt and fuse metal parts together or to cut through metal sheets or plates with precision.

Handheld Laser Welding and Cutting Machine

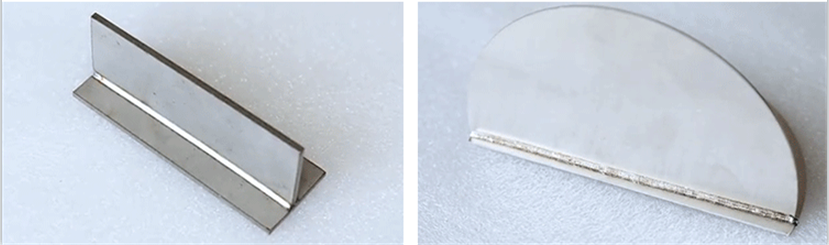

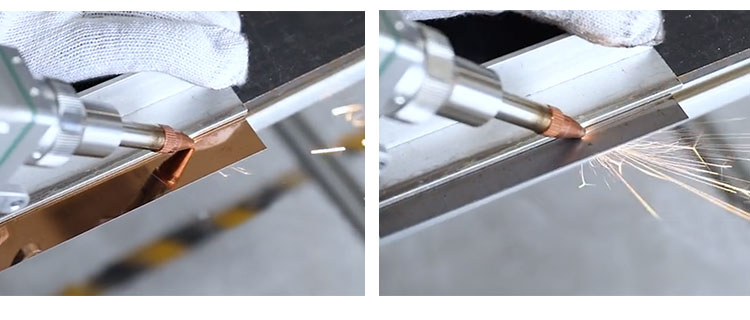

Laser Welding:With a laser welding torch, it is a laser welding machine that can weld aluminum, stainless steel, titanium, gold, silver, copper, nickel, chromium and other metals or alloys, and can also be applied to various welding metals between different materials , such as titanium-gold, copper-brass, nickel-copper, titanium-molybdenum, etc.

Laser Cutting: Laser cutting is a process that utilizes a highly focused laser beam to cut through materials with precision. With a laser cutting gun, it is a handheld laser cutting machine suitable for cutting various metal sheets and pipes.

Laser Cleaning: Laser cleaning is a non-contact surface cleaning process that uses a laser beam to remove contaminants, such as rust, paint, coatings, or debris, from the surface of a material. The laser energy vaporizes or ablates the unwanted material, leaving behind a clean surface. Laser cleaning is efficient, environmentally friendly, and does not involve the use of chemicals or abrasives.

Metal Laser Welding and Cutting Machine

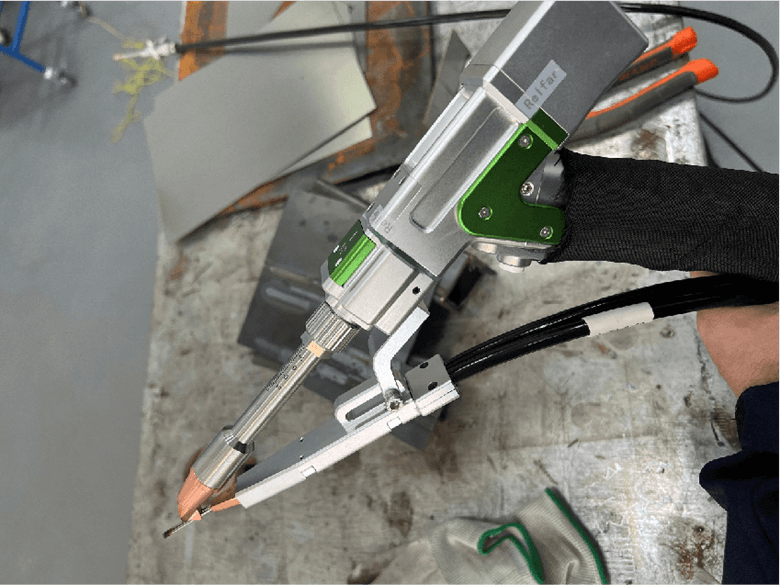

Portability

The handheld design allows operators to move the machine easily and access hard-to-reach areas. It offers flexibility in performing welding and cutting tasks on-site or in various locations within a workshop.

Laser Technology

The machine employs laser technology, typically using a fiber laser source. Fiber lasers provide high energy density, enabling precise and efficient welding and cutting of various metals, including stainless steel, carbon steel, aluminum, copper, and more.

Versatility

A handheld metal laser welding and cutting machine is suitable for a wide range of applications. It can handle tasks such as spot welding, seam welding, metal cutting, and even surface treatment processes like cleaning, ablation, and engraving.

Quick Setup and Operation

These machines are designed for ease of use. They usually have intuitive interfaces and user-friendly controls, allowing operators to set up and start the welding or cutting process quickly. This helps to save time and increase productivity.

Precise and High-Quality Results

Laser technology provides precise control over the welding and cutting process, resulting in high-quality and consistent results. The focused laser beam allows for narrow welds and clean cuts with minimal heat-affected zones, reducing the need for additional finishing processes.

Non-Contact Process

Laser welding and cutting are non-contact processes, meaning there is no physical contact between the machine and the workpiece. This reduces the risk of contamination or damage to sensitive or delicate materials.

Cost and Time Savings

Handheld metal laser welding and cutting machines can offer cost and time savings compared to traditional welding and cutting methods. The high-speed laser process, along with reduced setup and cleanup times, improves overall efficiency and throughput.

Multifunction Laser Welding and Cutting Machine

Multifunction laser welding, cleaning, cutting machine is composed of fiber laser generator, handheld laser gun, water chiller, and 5 in 1 control system, which is used for laser welding, cleaning and handheld cutting. Each handheld laser gun is portable, convenient, and easy to use.When you need to handle different processes, you can quickly change nozzles, lenses, and control systems. 5-in-1 Handheld Laser Welding Cleaning and Cutting Machine can not only cut and weld metal but also clean rust, paint, resin, coating, oil, and stains.To provide a more efficient and flexible solution for the market, the system comes with a process parameter library for common materials and thicknesses.For different application scenarios, it can easily and quickly replace the corresponding nozzle of the gun head, plug and play, so that the cumbersome processing becomes simple and the processing efficiency is higher.

It can also be called a 7-in-1 handheld metal laser welding and cutting machine, A 7-in-1 handheld metal laser welding machine is a versatile device that combines the functionality of five different welding methods into one compact, portable unit. It allows for precise and efficient metal welding using a handheld laser welder.he machine is easy to operate and portable and can provide you with flexible and innovative laser solutions. When you need to handle different processes, you can quickly change nozzles, lenses, and control systems. Laser Welding Cleaning and Cutting Machine can not only cut and weld metal but also clean rust, paint, resin, coating, oil, and stains.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.