Buyer Guide

Handheld Laser Cutting and Welding Machine

A handheld laser cutting and welding machine, also known as a portable laser cutter and welder, is a compact and versatile tool that combines the capabilities of laser cutting and welding in a handheld device. These machines utilize laser technology to perform precise cutting and welding operations on a variety of materials. Let’s explore the features, applications, and considerations associated with handheld laser cutting and welding machines.

Laser Cutting and Welding Machine

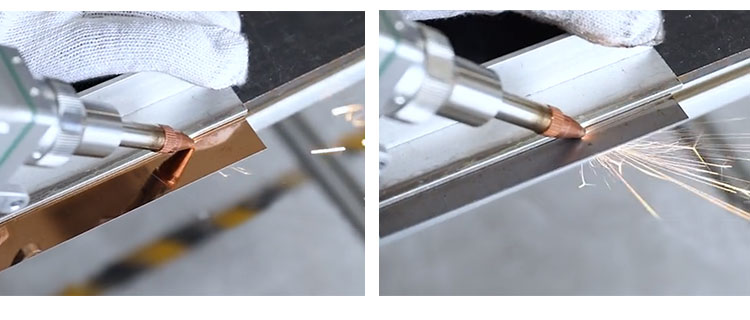

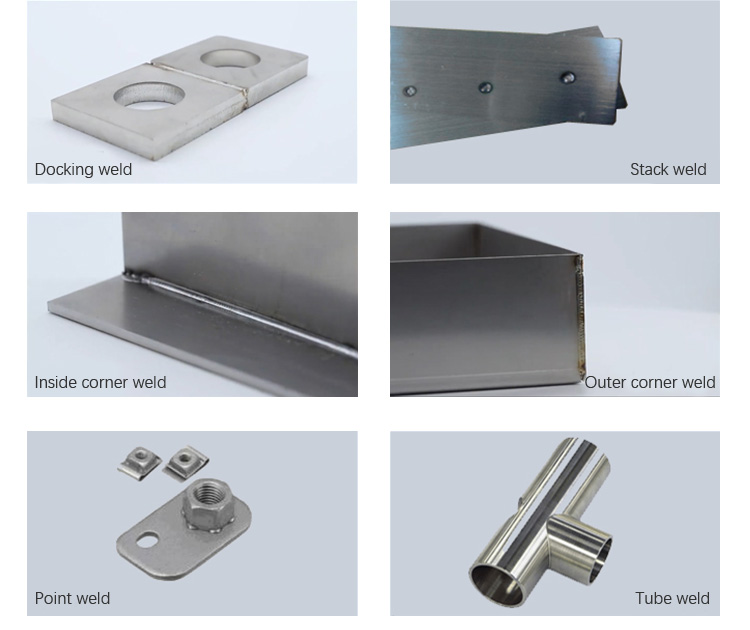

As a laser welding machine, the welding seam is flat and beautiful, with no grinding, no deformation, no welding marks, and the parts are firmly welded. Save time and increase efficiency. Welding on thin stainless steel plates, iron plates, galvanized plates and other metal materials can perfectly replace traditional argon arc welding, electric welding, and other processes. Hand-held laser welding machines can be widely used in complex and irregular welding processes in cabinets, kitchens, stairs, elevators, clothes hangers, ovens, stainless steel doors, window guardrails, power distribution boxes, stainless steel homes, and other industries.

As a laser cutting machine, it is very easy to operate for cutting all kinds of metals.

As a laser welding machine, the weld seam is smooth and beautiful; no need to polish, no deformation or welding scars, and the weld is firm. Save time and improve efficiency.

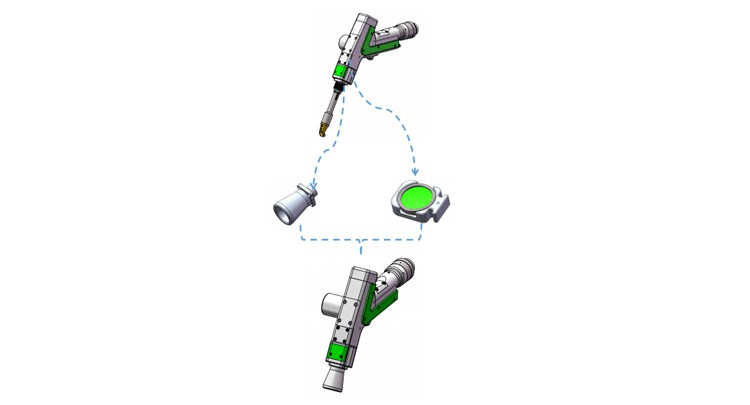

As a portable laser cutting machine, it is very easy to operate and can cut various types of metals. The portable laser gun is easy to carry and features a simple handheld configuration.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.