Laser Knowledge

Fiber Laser Beam Welding Machine

A fiber laser beam welding machine is a specific type of laser welding machine that utilizes a fiber laser as the laser source. Fiber lasers have gained popularity in various industrial applications due to their high power efficiency, compact size, and excellent beam quality. When used in laser beam welding, fiber lasers offer several advantages, including high-speed welding, precise control, and versatility.

Laser Beam Welding Machine

Laser beam welding offers several advantages, including high welding speeds, minimal distortion, narrow heat-affected zones, and the ability to weld a wide range of materials.

The technique provides numerous benefits, including high welding speeds, excellent weld quality, minimal distortion, and the ability to achieve precise and intricate welds.

Laser beam welding finds applications in various industries, including automotive, aerospace, electronics, medical device manufacturing, and more. It is commonly used to weld components such as sheet metal, tubes, and complex 3D structures.

Features of laser beam welding

High Energy Density

The laser beam provides a high energy density, allowing for rapid heating and melting of the workpiece. This results in fast welding speeds and reduced heat input to the surrounding material. Narrow

Heat-Affected Zone (HAZ)

Laser beam welding produces a narrow heat-affected zone, which refers to the area surrounding the weld joint that experiences thermal effects. The narrow HAZ helps minimize distortion and preserves the properties of the base material.

Precise Control

Laser beam welding offers precise control over the welding parameters, such as power, beam size, and focus. This control allows for accurate positioning and control of the weld, ensuring high-quality and consistent results.

Versatility

Laser beam welding can be used to join a wide range of materials, including metals and thermoplastics. It is suitable for both similar and dissimilar material combinations.

Automation and Integration

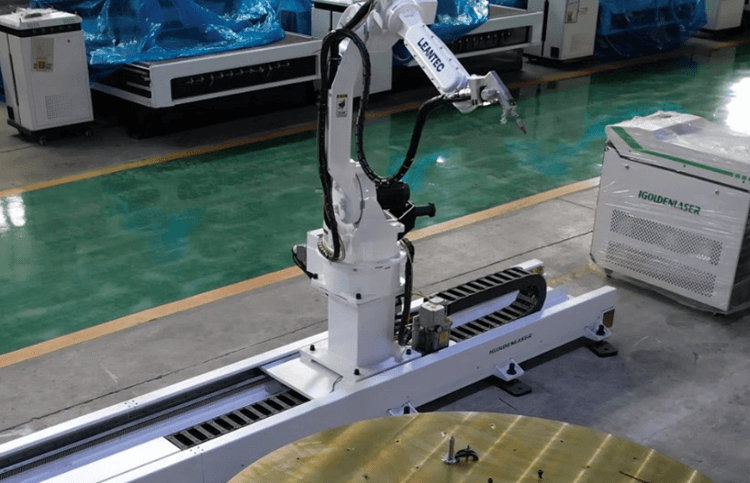

Laser beam welding can be easily integrated into automated production systems. It enables high-speed and repetitive welding operations, making it well-suited for industrial manufacturing.

Parts of fiber laser beam welding machine

- The laser beam welding machine is equipped with a fiber laser as the energy source. Fiber lasers generate the laser beam using a fiber optic cable that is doped with rare-earth elements such as ytterbium (Yb) or erbium (Er). These lasers provide high power output, good beam quality, and high efficiency.

- Optics System: Similar to other laser welding machines, a fiber laser beam welding machine incorporates an optics system. This system includes lenses, mirrors, and beam delivery components to focus and shape the laser beam. It ensures precise control over the welding process and allows the beam to be delivered to the workpiece accurately.

- Workstation: The workstation provides a platform where the materials to be welded are positioned. It typically includes fixturing or clamping mechanisms to hold the workpieces securely during welding. Motion control systems may be incorporated to move the workpieces or the laser beam during welding.

- Control System: The machine features a control system that allows operators to set and adjust welding parameters. It enables control over factors such as laser power, welding speed, pulse duration, and beam focus. The control system may have automation capabilities and may include monitoring and data logging features.

How to select a laser beam welding machine

Virmer takes care of its customers. We are interested in helping you with a choice of laser welding equipment that is suitable for your production needs. Therefore, we have compiled the most important criteria to focus on when purchasing laser beam welding machines.

Laser emitter

This criterion is based on two main parameters of an emitter: its power and its brand.

The power should be chosen according to the thickness and type of the metal to be processed. For example, to weld elements up to 3 mm thick, a power of 1000 W is quite enough. For thicker material, equipment with higher power is required.

The following brands of laser emitters are in the highest demand:

- IPG. The leader among the manufactures. Emitters of this brand are distinguished by high precision, double protection of the beam, and high quality of work performed.

- JPT. A cheaper analog of IPG. It also manufactures high quality laser emitters. However, it is a little less effective. We recommend using it for welding aluminium.

- Raycus. Another proven brand. Emitters of this manufacturer are designed for welding different types of metals except for non-ferrous metals.

- Max. These laser sources will be the perfect budget solution for production focused on aluminium and stainless steel welding.

All mentioned laser emitters perform perfectly providing high quality of welding. Thus, our company recommends considering them when you are choosing welding equipment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.