Buyer Guide

Exchange Table Fiber Laser Cutting Machine: Precision for Metal Cutting

Exchange Table Fiber Laser Cutting Machine offers a powerful and efficient solution for achieving precision cutting in a wide range of materials. With its advanced features, including laser power options, exchange table design, automation capabilities, user-friendly control system, and robust safety features, this machine delivers exceptional performance and productivity. By investing in this cutting-edge technology, industries can enhance their manufacturing processes, optimize productivity, and achieve superior results in material cutting applications.

Fiber Laser Cutting Machine

The Exchange Table Fiber Laser Cutting Machine is a cutting-edge industrial tool designed for precision and efficiency in material processing. This advanced machine utilizes fiber laser technology to deliver high-speed and high-precision cutting across a variety of materials, ranging from metals to non-metallic substances.

Featuring an innovative exchange table design, this machine enables seamless material loading and unloading while cutting operations are performed on the other table. This eliminates downtime and maximizes productivity, making it an ideal choice for high-volume production environments.The Exchange Table Fiber Laser Cutting Machine offers advanced automation features to optimize efficiency and reduce manual labor. With options for automatic loading and unloading systems, pallet changers, and material handling systems, the machine streamlines the production process and enhances productivity.

Double motor double chain automatic exchange platform, the platform is composed of a welded frame, with a support grid on which the workpiece is supported, and the worktable can bear a load of up to 1000KG; there are universal balls around the worktable, driven by Yaskawa servo motor, stable exchange speed within 8-15s, effectively preventing deviation and collision.

The two modes of linkage or independent operation can be set flexibly, which is convenient to deal with faults such as jams, easy to clean up the waste below, meet the loading and unloading of special plates, and improve production efficiency.

The machine provides a range of cutting area options to meet different production requirements. Examples include 1,500 mm x 3,000 mm or 2,000 mm x 4,000 mm, offering ample space for processing various sheet sizes. The larger cutting area ensures versatility and flexibility in handling different workpieces.

Fiber Laser Cutting Machine Key Features

Fiber Laser Technology: The machine incorporates state-of-the-art fiber laser technology, ensuring superior cutting quality and efficiency. This technology is known for its speed, precision, and ability to handle a wide range of materials.

Exchange Table Design: One of the standout features is the exchange table design. This allows for continuous operation as one table can be loaded or unloaded while the other is in use. This significantly reduces downtime and enhances overall productivity.

High Cutting Speed: The Exchange Table Fiber Laser Cutting Machine boasts impressive cutting speeds, making it suitable for various industrial applications. Whether it’s thin sheets or thicker materials, the machine can deliver quick and precise cuts.

Versatility in Material Compatibility: From metals like steel and aluminum to non-metallic materials such as plastics and composites, this laser cutting machine is designed to handle a diverse range of materials. It’s a versatile solution for industries with varied material processing needs.

Accuracy and Precision: Precision is paramount in industrial cutting processes, and this machine excels in delivering accurate cuts with minimal error margins. This is crucial for applications where intricate designs and tight tolerances are required.

User-Friendly Interface: The machine features an intuitive and user-friendly interface, making it accessible for operators with varying levels of expertise. The control panel allows for easy programming and adjustments, contributing to a smoother workflow.

Safety Measures: Safety is prioritized with built-in features such as laser beam guarding, emergency stop mechanisms, and compliance with industry safety standards. This ensures a secure working environment for operators.

Customizable Options: The Exchange Table Fiber Laser Cutting Machine often comes with customizable options to meet specific industry requirements. Whether it’s laser power, table size, or additional features, the machine can be tailored to suit diverse production needs.

Application of Fiber Laser Cutting Machine

Sheet Metal Fiber Laser Cutting Machine Applicable Industries

Machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Fiber Laser Cutting Machine with Exchange Platform Applicable Materials

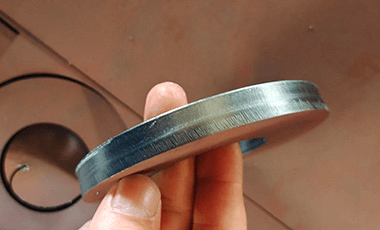

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate, metal pipe and tube, etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.