No products in the cart.

IGCL-HC(1000w-3000w)

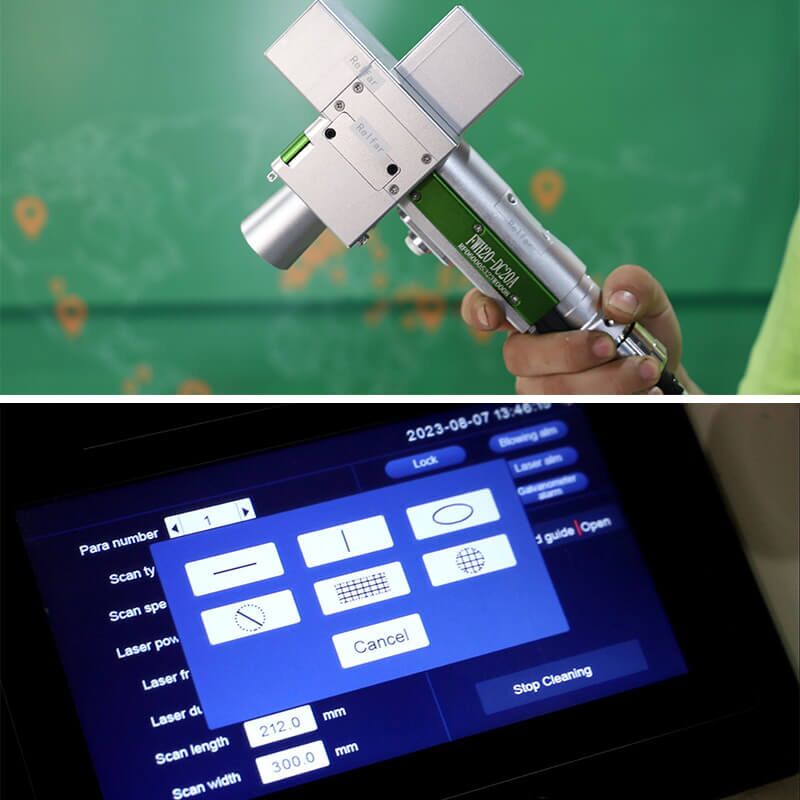

Laser Rust Cleaning Machine with Double Pendulum Head

The iGOLDENCNC Double Wobble Continuous Laser Cleaning Machine — on paper — is a powerful and flexible solution for industrial-grade cleaning tasks. it can offer substantial advantages over chemical or abrasive cleaning: efficiency, precision, environmental safety, and versatility across materials/coatings.

Advanced laser cleaning heads with a dual-wobble mechanism offer superior efficiency and coverage. Their ergonomic design ensures ease of use and durability, handling both large-scale and detailed cleaning tasks with precision.

The Double Wobble Continuous Laser Cleaning Machine represents the cutting edge in industrial cleaning technology, designed for superior performance and efficiency. This advanced system features dual-wobble laser heads that provide a continuous, high-coverage cleaning action, ensuring thorough and consistent removal of rust, coatings, contaminants, and residues from a wide range of surfaces. The innovative wobble mechanism enhances the cleaning speed and effectiveness, making it ideal for large-scale industrial applications.