No products in the cart.

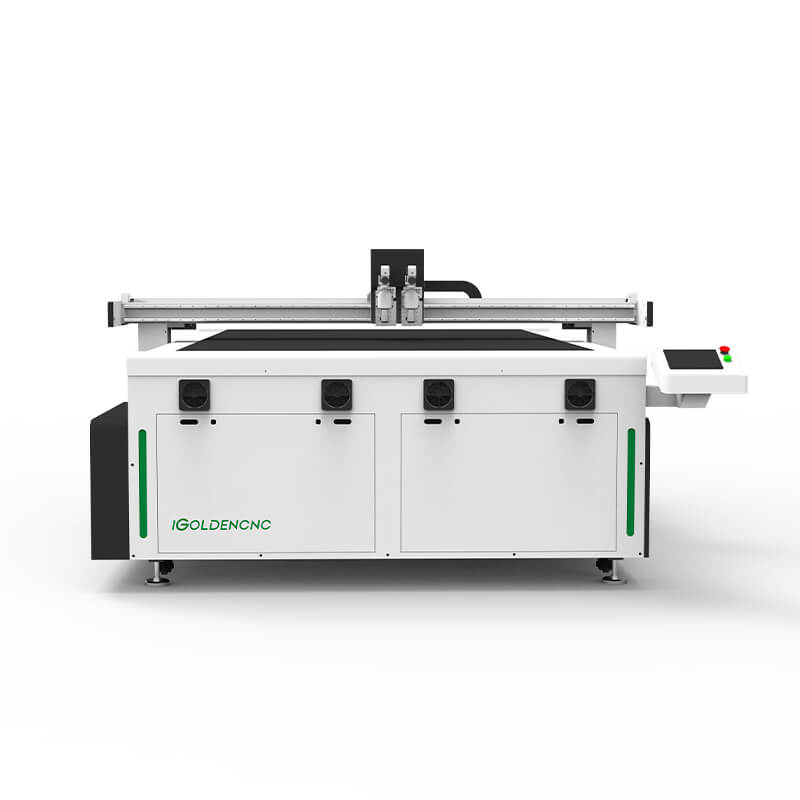

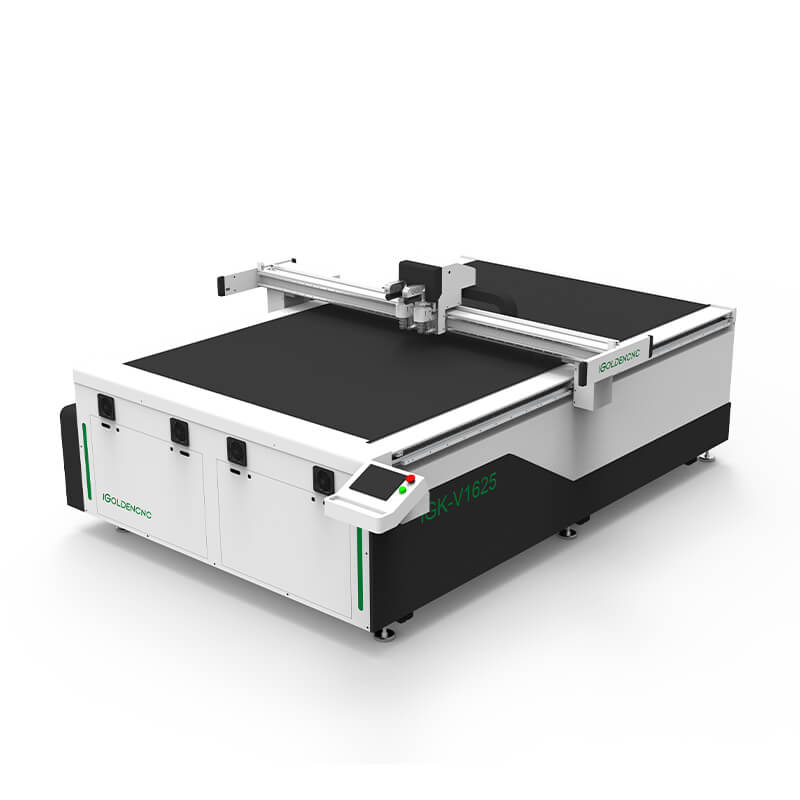

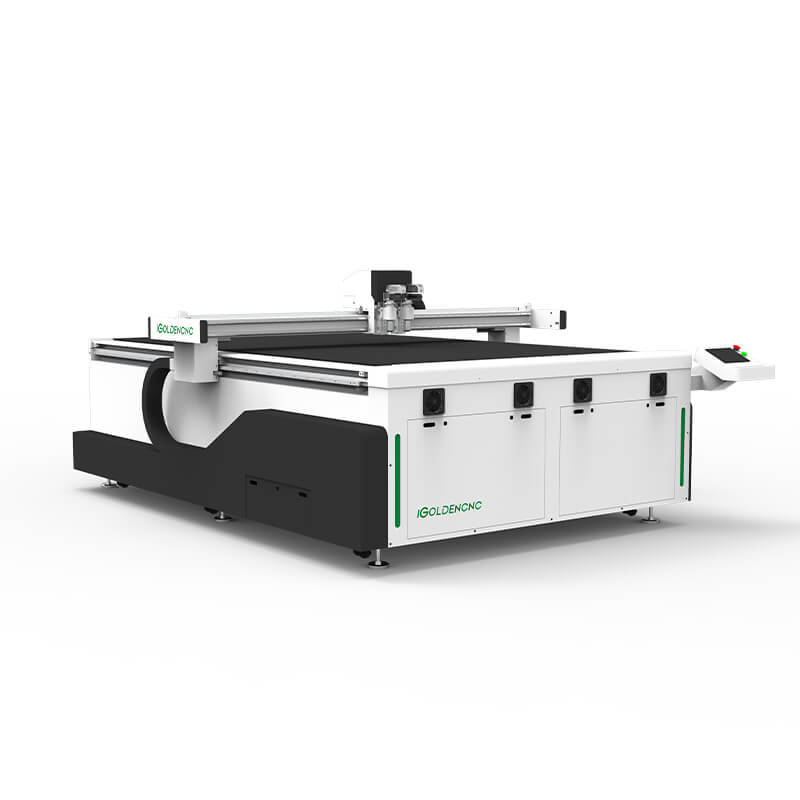

iGK-V1625

Digital Flatbed Cutter

The Digital knife cutting machine is a CNC equipment specially designed for high-precision cutting of flexible materials, and is widely used in industries such as automotive interiors, footwear, luggage, composite materials, and advertising signs. Through high-frequency vibration knife technology, rapid mold-free cutting of materials such as leather, sponge, carbon fiber, and non-woven fabric is achieved, featuring both high efficiency and flexibility. It meets the demands of small-batch customization and complex graphic processing, helping enterprises reduce mold-making costs and enhance production efficiency.

It has functions such as milling, vibration full-cut/half-cut cutting, and drawing. It can not only easily cope with various flexible materials, such as corrugated paper, honeycomb board, cardboard, foam, gray board, KT board, Chevron board, etc., but also can cut and mill hard plastics, acrylic, PVC and other advertising display materials. It is widely used in the cutting, proofing and small-batch production of materials in the packaging, printing, advertising, display and other industries.