Buyer Guide

4×8 CO2 Laser Cutter for Metal And Nonmetal

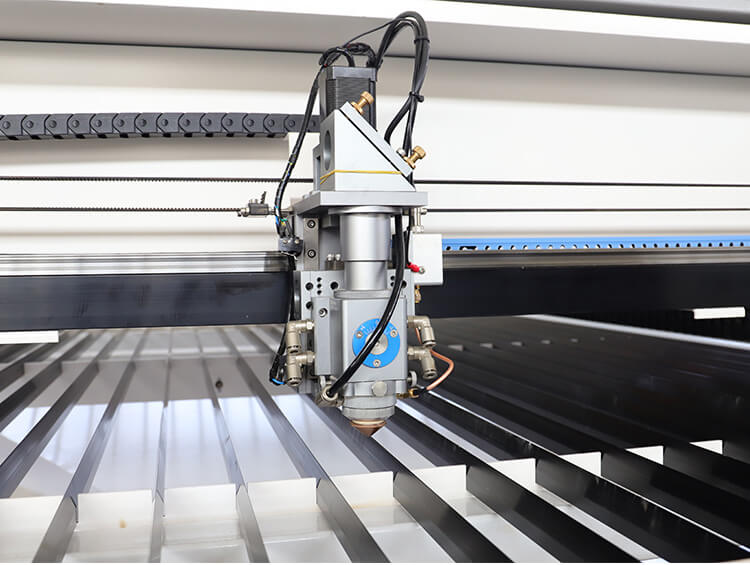

4×8 Co2 Laser etching machine uses co2 laser source to engraving and cutting metal and non-metal, .These machines utilize a CO2 laser source that can cut through non-metal materials such as leather, fabric, and plastic,glass, wood, acrylic, plastic, stainless steel, etc.The cutting size of 4×8 is adequate for the production needs of signage production. The belt drive ensures the machine’s performance while minimizing the machine’s manufacturing cost.

Feature Of Mixed Metal And Nonmetal Laser Cutting Machine:

- Adopting steel structure bed, the design is more scientific and the bed is more stable.

- One machine with dual functions. It is able to cut both non-metal and thin metal materials such as stainless steel, carbon steel, acrylic and wood.

- The high precision linear guide transmission ensures more steady of the cutting operation, thus maintaining high cutting precision and good stability.

- The quality of the cutting section is good because it adopts the mechanical follow-up cutting through system. The cutting head follows the height of the plate, and the position of the cutting point remains unchanged, so that the cutting seam is flat and smooth.

- Its cross beam uses high-strength aluminum alloy, which is lightweight, has small resonance, and operate more smooth.

Best 4×8 Mixed Metal And Nonmetal Laser Cutting Machine:

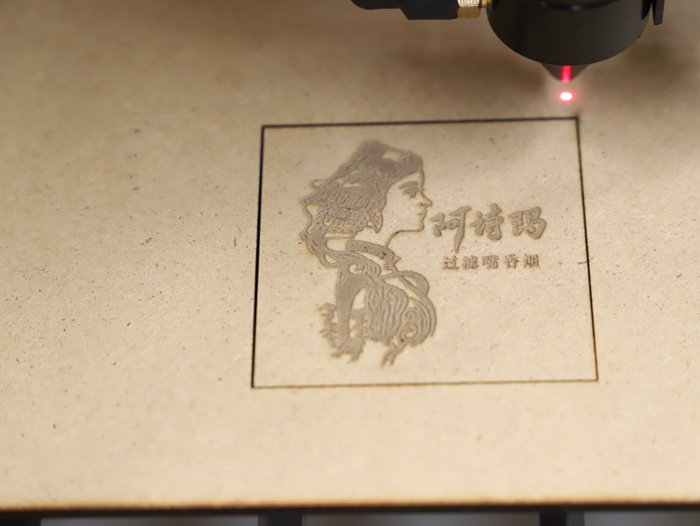

Advertising Industry: acrylic engraving and cutting, cutting and engraving of double- color plate and other advertising material

Leather Processing Industry: leather, fabric carved hollow

Arts And Crafts Industry: paper cutting, wood, bamboo products, leather, shell, ivory and other materials’ engraving and cutting

Model Industry: construction model, aviation and maritime models, wooden toys’ cutting.

Packaging Industry: printed rubber plate engraving and cutting, plywood cutting and laser cutter template cutting.

Decoration Industry: electrical and electronic industry materials engraving and cutting.

4×8 CO2 laser cutter machine for metal and non-metal cutting

When considering a CO2 laser cutter machine for metal and non-metal cutting, it’s advisable to consult with manufacturers or suppliers who specialize in these types of machines. They can provide specific recommendations based on your application requirements and guide you in selecting a machine that meets your needs in terms of power, working area, cutting capabilities, and safety considerations.

- Laser Power: Metal and non-metal laser cutting machines typically require higher laser power to effectively cut through metal materials. The power range can vary depending on the thickness and type of metal being cut. For non-metal materials, lower power settings are generally sufficient.

- Dual-Purpose Cutting Head: These machines are equipped with a dual-purpose cutting head that can accommodate both metal and non-metal cutting. The cutting head may include a metal cutting nozzle and a non-metal cutting nozzle, allowing for quick and easy switching between materials.

- Material Thickness: The cutting capability for metal materials is often dependent on the thickness. 4×8 CO2 laser cutters for metal and non-metal cutting can handle metal sheets of varying thicknesses, ranging from thin gauge materials up to several millimeters or even thicker, depending on the machine’s power and specifications. Non-metal materials can typically be cut across a wide range of thicknesses.

- Gas Assist: When cutting metal materials, a gas assist system is often used to improve the cutting process. Compressed gases, such as oxygen or nitrogen, are directed through the cutting nozzle to help blow away molten metal and assist in achieving clean cuts.

- Software and Parameters: CO2 laser cutter machines for metal and non-metal cutting are typically controlled by specialized software. The software allows for precise control of cutting parameters, such as laser power, cutting speed, and gas flow, to optimize cutting performance for different materials.

- Bed Size and Working Area: The bed size and working area of these machines can vary depending on the specific model. It’s important to consider the size of the materials you intend to work with and ensure that the machine’s working area can accommodate them.

- Safety Considerations: Metal cutting with a CO2 laser can produce potentially hazardous fumes and vapors. Proper ventilation and safety measures, such as fume extraction systems and appropriate protective equipment, should be implemented to ensure a safe working environment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.