Buyer Guide

Brass Laser Cutting Machine

In the world of precision metal fabrication, technological advancements have played a significant role in enhancing efficiency and accuracy. One such innovation is the brass laser cutting machine. This cutting-edge equipment has revolutionized the way brass materials are processed, offering unparalleled precision, speed, and versatility.

The future prospects for brass laser cutting machines are promising. As technology continues to advance, we can expect further improvements in terms of speed, precision, and efficiency. Additionally, the integration of artificial intelligence and machine learning algorithms may enhance the capabilities of these machines, allowing for even more complex and intricate cuts.

Brass Laser Cutting Machine

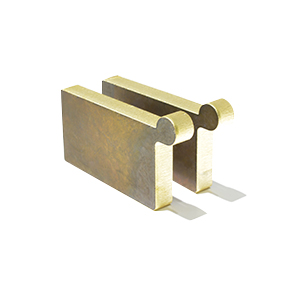

A brass laser cutting machine is a sophisticated piece of equipment that utilizes laser technology to precisely cut brass materials with exceptional accuracy. It employs a high-powered laser beam to melt, burn, or vaporize the brass, creating intricate and precise cuts. These machines are equipped with advanced computer numerical control (CNC) systems that allow for precise control over the cutting process, resulting in high-quality finished products.

The working principle of a brass laser cutting machine involves the interaction between the laser beam and the brass material. The machine directs the laser beam onto the surface of the brass, which heats the material to its melting point. As the laser beam moves along the predetermined cutting path, it melts and vaporizes the brass, creating a narrow kerf. The high-pressure gas, typically nitrogen or oxygen, blows away the molten material, leaving behind a clean and precise cut.

Can brass laser cutting machines cut through thick brass plates?

Yes, brass laser cutting machines are capable of cutting through thick brass plates. The cutting capacity of these machines depends on various factors such as the power of the laser, the type of gas used, and the thickness ofthe brass material. However, it is important to ensure that the machine used has the necessary power and capabilities to handle thicker materials.

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Brass N₂ | 1 | 2.0-3.5 | 4.5-6.0 | 4.5-8.0 | 8.0-12.0 | 10.0-16.0 | 20.0-32.0 | 23.0-30.0 | 40.0-55.0 | 1 |

| 2 | 0.7-1.0 | 1.0-2.0 | 2.5-3.5 | 3.5-5.0 | 6.0-8.0 | 9.0-11.0 | 9.0-13.0 | 30.0-35.0 | 2 | |

| 3 | 2.0-3.0 | 2.5-4.0 | 5.0-6.5 | 5.0-6.5 | 11.0-18.0 | 3 | ||||

| 4 | 1.6-2.2 | 3.0-4.5 | 3.0-5.2 | 7.5-10.0 | 4 | |||||

| 5 | 0.7-1.2 | 1.5-2.0 | 1.8-3.0 | 5.5-7.0 | 5 | |||||

| 6 | 1.0-1.6 | 1.3-2.0 | 3.2-4.5 | 6 | ||||||

| 8 | 0.6-0.8 | 1.5-2.2 | 8 | |||||||

| 10 | 0.7-1.2 | 10 | ||||||||

Applications of Brass Laser Cutting Machines

Brass laser cutting machines find applications in various industries due to their versatility and precision. Some of the key industries that benefit from these machines include:

1 Automotive Industry

In the automotive industry, brass laser cutting machines are used to fabricate intricate components such as gears, brackets, and exhaust systems. The precision and speed offered by these machines ensure that the components meet the strict quality standards of the industry.

2 Electronics Industry

The electronics industry relies heavily on brass laser cutting machines for the production of intricate circuit boards and electronic components. The ability of these machines to cut through brass with micron-level precision is crucial in ensuring the functionality and reliability of electronic devices.

3 Jewelry Industry

Brass laser cutting machines have also found their way into the jewelry industry. They are used to create intricate designs and patterns on brass jewelry pieces, allowing jewelers to offer unique and customized products to their customers.

4 Architectural Industry

In the architectural industry, brass laser cutting machines are used to fabricate decorative panels, signage, and intricate architectural elements. The precision and versatility of these machines enable architects and designers to bring their creative visions to life.

Advantages of Brass Laser Cutting Machine

1 Precision and Accuracy

One of the primary advantages of brass laser cutting machines is their exceptional precision and accuracy. The high-powered laser beam, coupled with advanced CNC systems, allows for precise control over the cutting process, resulting in clean and precise cuts.

2 Versatility

Brass laser cutting machines offer unparalleled versatility. They can cut through various thicknesses of brass materials, ranging from thin sheets to thick plates. Additionally, these machines can create intricate designs and patterns, making them suitable for a wide range of applications.

3 Efficiency and Speed

Compared to traditional cutting methods, brass laser cutting machines offer significantly higher efficiency and speed. The automated nature of these machines, coupled with their high cutting speeds, allows for faster production times and increased productivity.

4 Minimal Material Waste

Due to the precise nature of the cutting process, brass laser cutting machines minimize material waste. The narrow kerf created by the laser beam ensures that the amount of material removed is minimal, resulting in cost savings and reduced environmental impact.

Pingback: Laser Cutting Brass, Aluminum, and Stainless Steel: Guide