Laser Knowledge

What Are CNC Digital Knife Cutting Machines Used For?

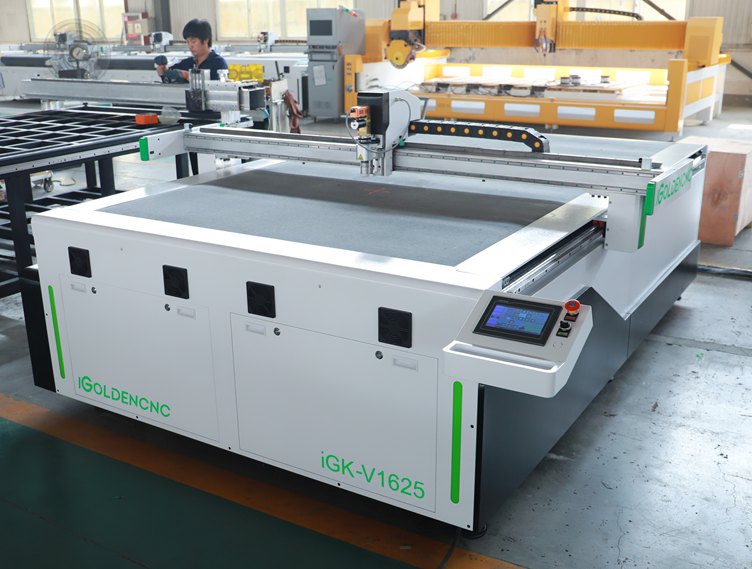

CNC digital knife cutting machines are specialized cutting systems that use digitally controlled blades to slice through soft to medium-hard materials with high precision. Commonly employed for textiles, leather, foam, rubber, foam board, cardboard, and certain flexible plastics, these machines offer fast setup, repeatable edge quality, and the ability to nest parts efficiently. Whether you’re producing apparel, automotive interiors, signage, packaging prototypes, or custom upholstery, a CNC knife cutter can streamline production without the mess and cost of traditional cutting methods.

CNC Digital Knife Cutting Machines Used For

CNC digital knife cutters are used for the cuts of special-shaped graphics made of non-metallic flexible materials. It can quickly complete various processes such as full-cut, half-cut, milling, perforate, crease and mark, solving the problems of special-shaped picture cuts, improving production efficiency, and reducing labor cost. It can reduce the defect rate caused by manual tool errors, help users complete high-quality cuts faster, more stable, and more accurately at low cost, improve user market competitiveness, and seize more market shares. Digital flatbed cutters are used in advertising packaging, clothing and footwear, automotive interiors, luggage, composite materials and other industries.

Graphics Industry

Applications: Outdoor advertising, displays, traffic signs, fleet graphics, exhibits, illuminated signage, store décor, decals, floor graphics, etc.

References: 3M, Airbus, Avery Dennison, Christinger, Fair-play, Fastsigns, Graphics Gallery, Imaba, Lufthansa, netService, PlotFactory, Quarmby Colour Studio, Sin Fung Advertisement, Stylographics, Supersine Duramark, Zebra Graphics, etc.

Packaging Industry

Applications: Printed or unprinted packaging, POP/POS displays, foam inserts, dies making.

References: Beiersdorf, Chesapeake, Edelmann, Hasbro Toys, Heidelberg, International Paper, Long Chen Paper, Mauro Benedetti, Mondi, Packaging Cooperation of America (PCA), Panther Packaging, Philip Morris, sanovi aventis, SCA,Seda, Smurfit Kappa, STI, TetraPack, Thimm Verpackung, Triwall, etc.

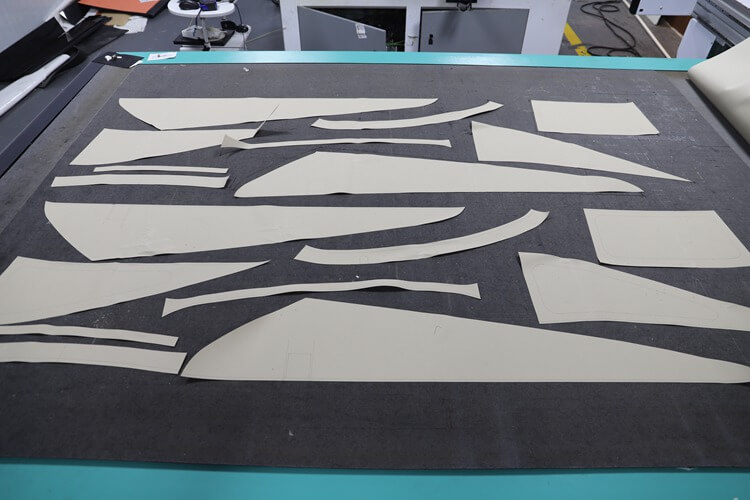

Leather Industry

Applications: Shoes, garments, upholstery, handbags, briefcases, car and airplane seats, etc.

References: Adidas, Akris, Bally, Cavallo, Clarks, Ecco, Gabor, Geox, Gucci, Louis Vuitton, Nike, Prada, Puma, Recaro, Rolf Benz, Samsonite, de Sede, Sergio Rossi, Timberland, etc.

Textile Industry

Applications: Garments, upholstery, airbags, flags, sun shades/umbrellas, car and airplane seats, etc.

References: BMW, Diesel, Ford, Hugo Boss, Interstuhl, Jil Sander, Joop, Levi Strauss, Mercedes, Triumph, Volkswagen, Zodiac, etc.

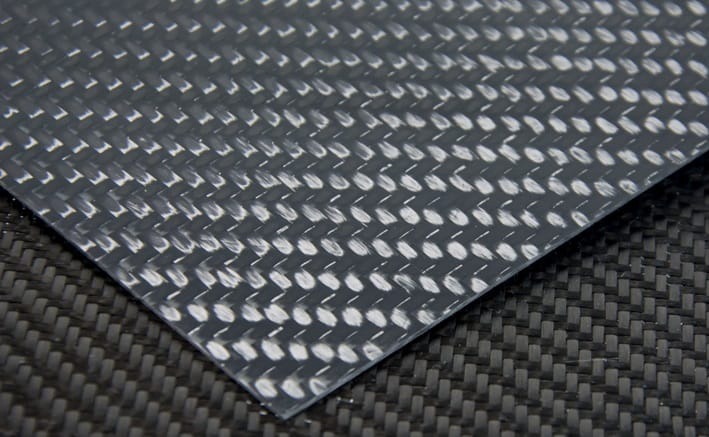

Composite Industry

Applications: Defense, functional textiles, rotor blades for wind wheels and helicopters, aircraft and automotive parts, etc.

References: 3C-Carbon Composite Company, ACE, Airbus, Audi, Bell Helicopter, BMW, Carbo Tech, DLR, Dyneema, Eurocopter, FACC, Ferrari, McLaren, Pilatus, Red Bull Racing, Scuderia Toro Rosso, SGL Group, ThyssenKrupp, etc.

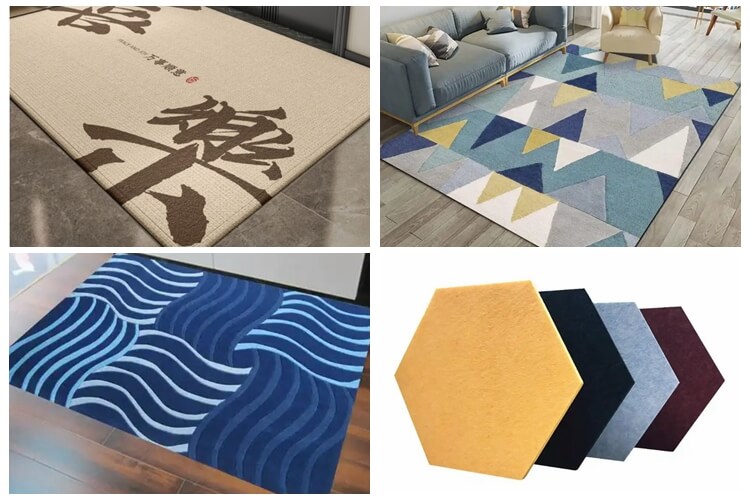

Techtex Industry

Applications: Truck tarpaulin, carpets, awnings, hot-air balloons, sails, outdoor equipment, inflatable boats, etc.

References: Badertscher, Barrisol, Bieri, Daedler, de Sede, Eschenbach Zeltbau, Estrella Betten, Höcker HTS Structures, interstuhl, Kusch+Co, Quelli In Luce, Ruckstuhl, Sachsen Fahnen, W.Schillig, etc.

Specialty Applications

Applications: Adhesives, gaskets and filter materials, PVB film for auto glass, architectural models, foam, wood veneer, floor coverings, film for solar and photovoltaic systems, aluminium foil, watch faces, etc.

References: ABB, Daimler Chrysler, Dell, Ferrari, Herzog & De Meuron, LG Electronics, Pilkington, Porsche, Procter & Gamble, Red Bull F1-Team, Rolex, SaintGobain Sekurit, Samsung Electronics, Swatch, etc.

CNC Digital Knife Cutting Table Advantages

1. High speed with high quality, its cutting speed is 5-8 times faster than laser cutter.

2. Advanced computerized CNC control system, which is easy to operate with ethernet port.

3. Working without air pollution, no burnt edge, uniform in color.

4. It can cut soft materials with perfect edges and corner.

5. It adopts Japan YASKAWA servo motor and drive, fast speed with high precision.

6. It can be equipped with different knife tools & blades to meet a variety of needs.

7. Special safety sensing device meets the European standard.

8. Intelligent tabletop mapping.

9. Automatic tool calibration.

10. Multi-task repeat cutting, intelligent absorption.

How They Work: Core Principles and Workflow

- Design and planning: Create a pattern or component layout in CAD software and bring it into CAM software to generate cutting paths.

- Material setup: Load the material (fabric, leather, foam, etc.) on the bed or feeder system; ensure proper tension and alignment.

- Tooling and parameter selection: Choose the right knife type (oscillating, drag, rotary) and set cutting speed, blade depth, and feed rate.

- Cutting: The machine follows the programmed paths, making precise contour cuts, perforations, or shapes.

- Finishing and inspection: Remove cut parts, inspect edge quality, and perform any required sewing, binding, or assembly steps.

- Nesting and optimization: Efficiently arrange parts on the material to minimize waste and reduce cycle times.

Conclusion

CNC digital knife cutting machines offer fast, flexible, and cost-effective cutting for a wide range of soft and semi-rigid materials. By choosing the right blade technology, bed or feed system, and CAM workflow, you can achieve high-quality edges, tight tolerances, and scalable production for textiles, leather, foam, packaging, and more.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.