Buyer Guide

Wholesale Fiber Laser Cleaning Machine

When it comes to industrial cleaning applications, a wholesale fiber laser cleaning machine can be a game-changer for businesses looking to streamline their operations and improve efficiency. As someone who values precision and effectiveness in industrial processes, the use of fiber laser technology for cleaning purposes is a fascinating development to explore.

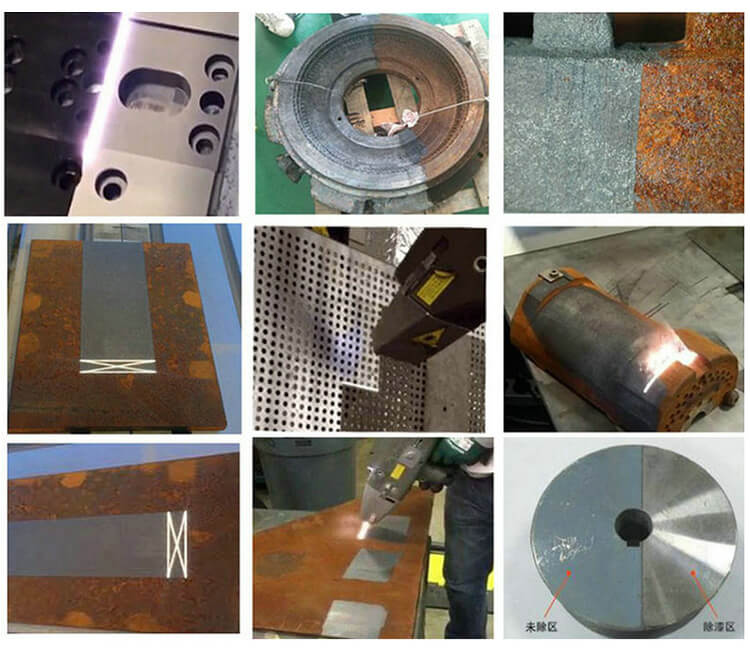

Fiber laser cleaning machines utilize high-energy laser beams to remove contaminants, coatings, rust, and other unwanted materials from various surfaces with incredible precision and speed. The non-contact nature of laser cleaning minimizes the risk of damage to the underlying surface, making it a safe and effective cleaning solution for a wide range of materials.

Wholesale Fiber Laser Cleaning Machine

Why Choose Us for Wholesale?

-

Bulk Discounts – Competitive pricing for distributors and resellers

-

OEM/ODM Service – Brand customization and packaging

-

Global Shipping – Fast delivery with export-compliant packaging

-

After-Sales Support – 24/7 technical support and parts availability

-

Training Available – Online & on-site operation training

Fiber Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Welding Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Laser Cleaning Machine

Manual, Automatic, and Robotic Type

Laser cleaning machines come in manual, automatic, and robotic integration types. Manual operation offers high flexibility, making it suitable for small batches or complex-shaped parts, but requires skilled operators. Automatic and robotic laser cleaning systems are designed for large-scale, continuous industrial cleaning tasks, providing high efficiency and consistent results, although the equipment cost is relatively higher.

By offering wholesale fiber laser cleaning machines, suppliers can provide businesses with cost-effective and efficient solutions for their cleaning and maintenance needs. Whether it’s removing rust from metal components, cleaning graffiti from walls, or restoring historical artifacts, fiber laser cleaning machines offer a modern and innovative approach to surface cleaning.

Continuous and Pulsed Laser Cleaning Machines

Continuous Laser Cleaning Machines

Continuous laser cleaning machines emit a steady, uninterrupted beam of laser energy, ideal for smooth and uniform cleaning across large surfaces.

The consistent laser flow heats and vaporizes contaminants, making these machines effective for large-scale or repetitive tasks.

Pulsed Laser Cleaning Machines

Pulsed laser cleaning machines emit laser energy in short, controlled bursts, allowing for precise and targeted removal of contaminants. The brief pulses minimize heat buildup, protecting sensitive surfaces from damage.

Fiber Laser Cleaning Machine Key Features:

-

Laser Power Options: 100W, 200W, 500W, 1000W, 1500W, 2000W,3000w,6000w

-

Cleaning Method: Non-abrasive, non-contact laser ablation.

-

Supported Materials: Rusted steel, aluminum, copper, cast iron, painted surfaces, oxide layers, oil stains.

-

Control System: Touchscreen interface, built-in presets for different cleaning tasks.

-

Laser Source: High-performance fiber laser (Raycus, JPT, or IPG available).

-

Cooling System: Air-cooled (for 100–200W) or water-cooled (for 500W+).

Applications:

-

Rust Removal – Fast and residue-free cleaning of metal oxidation.

-

Paint Removal – Strip coatings without damaging the base material.

-

Oil Stain & Oxide Removal – Effective pre-treatment for welding or painting.

-

Mold & Resin Cleaning – Precise cleaning of injection molds or electronic parts.

Fiber Laser Cleaning Machine of benefits and applications

Fiber laser cleaning machines utilize the intense, focused energy of a fiber laser to remove contaminants, coatings, and impurities from a wide range of surfaces with remarkable accuracy and speed. These advanced systems offer a transformative solution that surpasses the capabilities of traditional cleaning methods.

- Unparalleled Precision: Fiber laser cleaning machines can target specific areas with pinpoint accuracy, removing unwanted materials without damaging the underlying surface. This level of precision is essential for delicate or intricate cleaning applications.

- Enhanced Cleaning Efficiency: The high-energy, focused laser beam of these machines can quickly and effectively remove even the most stubborn contaminants, significantly reducing the time and labor required for cleaning tasks.

- Versatility in Surface Types: Wholesale fiber laser cleaning machines can be used on a diverse array of materials, including metals, plastics, composites, and ceramics, making them a versatile solution for a wide range of industries.

- Automated and Intelligent Features: Many fiber laser cleaning machines feature advanced automation capabilities, such as CNC (Computer Numerical Control) systems and robotic integration, enabling consistent, high-quality cleaning results with minimal human intervention.

- Improved Environmental and Workplace Safety: Fiber laser cleaning is a dry, non-abrasive process that eliminates the need for harsh chemicals or solvents, reducing the environmental impact and promoting a safer work environment for operators.

What is a Fiber Laser Cleaning Machine?

A fiber laser cleaning machine uses a high-powered laser beam to remove unwanted layers (rust, paint, oxides, oil, etc.) from metal and non-metal surfaces without physical contact or chemical solvents. It works through laser ablation, breaking down contaminants at a microscopic level and vaporizing them safely.

Laser rust removal does not require any chemicals, and the waste after rust removal is solid and harmless powder, which can completely solve the environmental pollution problem caused by chemical rust removal; and laser rust removal is a non-contact processing method, let alone worry about it. Damage or deformation to the workpiece, and the initial investment of the laser rust removal system is high, but it can be used stably for a long time, with a service life of up to 10 years, low operating cost, high speed, high efficiency, time saving, and can be quickly obtained. The return on investment, in the long run, is lower cost than the blast machine method.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.