Buyer Guide

How to a Choose Tube Fiber Cutting Machine

Choosing a tube fiber laser cutter involves assessing your specific application needs, materials, production volume, and budget. A tube fiber laser cutter is a specialized CNC laser machine designed for cutting round, square, rectangular, and other shaped tubes or pipes made of metal (like steel, aluminum, brass, etc.).

It’s also important to evaluate the power and speed capabilities of the laser cutter to ensure it can handle the workload efficiently. Additionally, look for features like automatic tube loading and unloading systems, rotary axis options for cutting curved surfaces, and software compatibility for seamless operation.

Don’t forget to consider the reputation and support of the manufacturer when making your decision. A reliable supplier with a good track record of customer service can provide you with the necessary guidance and assistance throughout the machine’s lifespan.

Choose Tube Fiber Cutting Machine

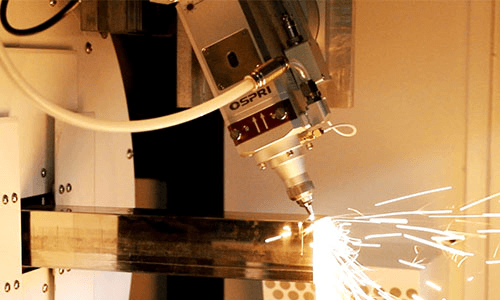

Laser tube cutters are very fast and accurate computer controlled cutters that oàer numerous beneÕts to a variety of manufacturers for cutting metal plates, sheets and pipes. In many cases, they are your best bet. Cutting pipe to achieve the power to cut to the bottom, and the length of accurate, no coke edge.

Metal tube laser cutting machine Especially for laser cutting metal tube of round, square, rectangular, triangle, oval, waist tube and other shaped tube & pipe. The tube outer diameter can be 20-200mm, length 8m.A round tube and square tube laser cutting machine is a specialized industrial equipment designed to cut both round and square tubes with high precision and efficiency using laser technology. It is capable of cutting various metals, including steel, stainless steel, aluminum, brass, and copper.

Why should you consider using a tube fiber laser cutter?

- Laser cutting is a very precise cutting technique.

- Due to the small thermal impact zone, the risk of material deformation is limited.

- Laser cutting is a very fast and eÞcient cutting process.

- Laser tube cutters are highly automated computer-controlled machines that limit the need for operator interfaces – unmanned systems.

- Laser tube cutting machine cutting precision and precision produce very narrow incisions, providing more tightly nested parts, thereby minimizing material waste.

- Laser tube cutting machine will not produce toxic smoke when cutting.

Key Factors to Consider When Choosing a Tube Fiber Laser Cutter

1. Material Type and Thickness

Supported Materials: Ensure the machine supports the metals you plan to cut (e.g., carbon steel, stainless steel, aluminum alloys).

Laser Power: Choose power based on material thickness:

1kW – 2kW: Thin sheet/tube (<6mm)

3kW – 6kW: Medium thickness (up to 16mm)

8kW – 12kW+: Thick tubes and high-speed cutting

2. Tube Dimensions

Tube Diameter Range: Make sure the machine can handle your smallest and largest tube diameters.

Length Capacity: Common lengths are 3m, 6m, or even 9m.

Tube Shape Compatibility: Round, square, rectangular, oval, angle, channel.

3. Chuck System

Automatic vs. Manual Chuck: Automatic chucks offer faster loading and better centering.

Number of Chucks: Dual-chuck systems provide better stability for long tubes.

4. CNC Control System and Software

Look for user-friendly, stable, and intelligent systems (e.g., CypCut TubePro, TubeCut, or proprietary software).

Check for nesting software, cad/cam compatibility, and real-time monitoring.

5. Cutting Precision and Speed

Check:

Positional Accuracy (±0.05 mm or better)

Cutting Speed (varies with material and power)

Look for automatic centering systems, servo motors, and high-quality linear guides.

6. Automation Options

Automatic loading/unloading systems: Increases productivity.

Seam tracking and real-time correction: Essential for precise tube cutting.

7. Maintenance and Support

Choose a brand with:

Local service support

Spare parts availability

Remote diagnostics and training

8. Budget and ROI

Entry-level (1.5kW, manual loading): $30,000–$60,000

Mid-range (3kW, auto chuck): $60,000–$100,000

High-end (6kW+, full automation): $100,000+

Calculate ROI based on cutting hours, labor savings, and material yield.

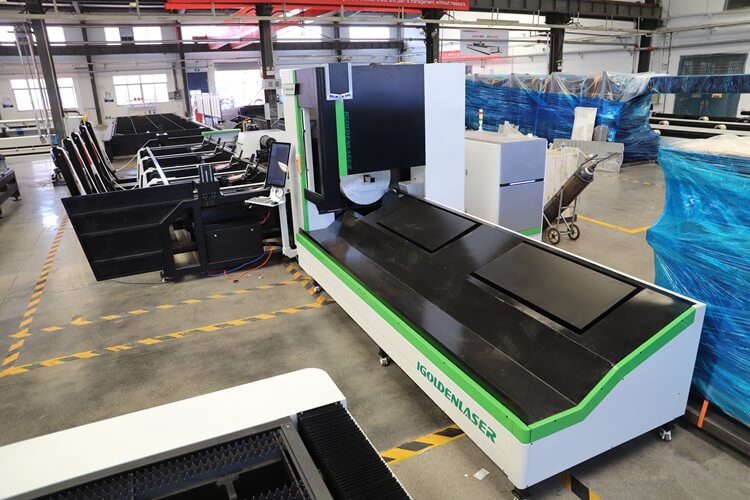

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.