Laser Knowledge

What is Laser Cutting?

Laser cutting has become one of the most important manufacturing processes in modern industry, yet many people remain unclear about what it actually is and how it works. At iGoldenLaser, we explain laser cutting technology to curious newcomers and experienced manufacturers daily. This comprehensive guide demystifies laser cutting, explaining the fundamental principles, processes, advantages, and applications that make this technology indispensable across industries from aerospace to arts and crafts.

Laser cutting is a technology that uses a high-powered laser beam to precisely cut, engrave, or etch materials.

The process involves focusing the laser onto the material, where the intense energy either melts, burns, vaporizes, or blows away the material, creating a cut or engraved pattern. In this article, we will delve into laser cutting, its history, the various types, cutting methods, laser cutting design software and much more.

Laser cutting: history

The history of laser cutting is closely tied to the development of laser technology itself. It all started in the 1960s when Theodore H. Maiman, an American physicist, developed the first working laser at Hughes Research Laboratories. This was a ruby laser, marking a pivotal moment that paved the way for a technology that would revolutionize numerous industries. A few years later, in 1965, the first laser cutting machine was developed by Western Electric Engineering Research Center. In the 1970s, lasers began to find practical industrial applications. A significant milestone was achieved by Peter Houldcroft at The Welding Institute in the UK, who developed the first laser-assisted oxygen jet cutting process. This innovation allowed metals to be cut effectively, expanding the potential uses of lasers in industry.

The 1980s marked an era of significant improvements, with increased precision and power in laser technology. The integration of Computer Numerical Control (CNC) systems with laser cutting machines allowed for automated processes and the creation of increasingly complex designs. In the early 1990s, fiber lasers began to emerge, offering higher efficiency and superior performance in cutting metals. These lasers became essential tools in advanced industries such as automotive and aerospace.

With the start of the 2000s, laser cutting became more accessible and widespread. Advances in laser power, speed, and control made this technology indispensable across a wide range of applications. Moreover, the development of compact, lower-cost laser machines allowed small businesses, craftsmen, and schools to leverage this innovative technology. In recent years, laser cutting has continued to evolve, with the integration of automated systems and artificial intelligence, making the machines more efficient and smarter.

How does laser cutting work?

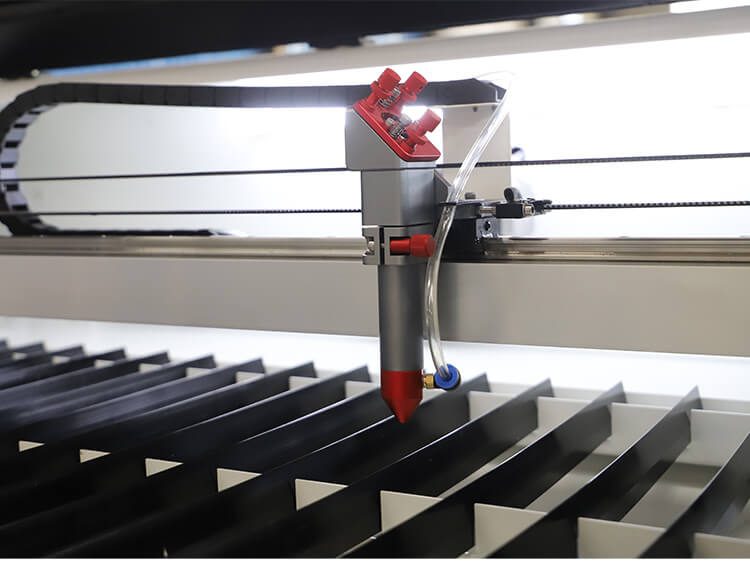

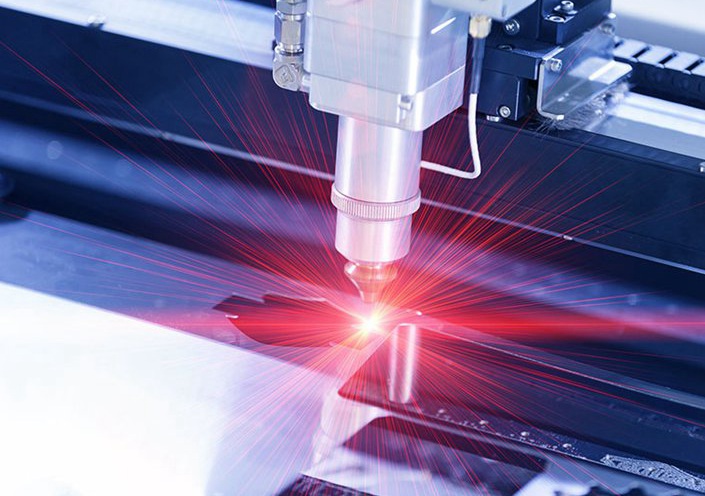

The process begins with generating the laser beam using a laser source. The light from the laser source is amplified and concentrated to produce a powerful, coherent beam of light, typically in the infrared spectrum, which is invisible to the human eye. The laser beam is directed through a series of mirrors and lenses to focus it onto a specific point on the material. The focal point is incredibly small, allowing for high precision.

When the focused laser beam hits the material, it heats it to the point of melting, burning, or vaporization, depending on the material and laser power. For cutting, the laser moves along a predetermined path, guided by CNC (Computer Numerical Control) to follow the desired design. The entire cutting process is controlled by a CNC system, which ensures the laser moves precisely along the desired path. The CNC system interprets the design (usually a CAD file) and controls the movement of the laser head and the material.

The result is a clean, precise cut with smooth edges, often requiring little to no finishing work. The quality of the cut depends on the material, laser settings, and the precision of the CNC system.

What Makes Laser Cutting Different

Non-Contact Processing: No physical cutting tool touches the material. This eliminates tool wear, prevents material deformation from cutting pressure, and enables processing delicate materials impossible to cut mechanically.

Thermal Cutting: Material removal occurs through heat rather than mechanical force. The concentrated energy melts or vaporizes material locally while leaving surrounding areas largely unaffected.

Digital Control: Every cut follows computer instructions precisely. Change designs instantly through software without creating new templates, dies, or tooling—revolutionary flexibility compared to traditional manufacturing.

Narrow Cutting Width: The laser beam creates extremely narrow cuts (kerfs) typically 0.1-0.5mm wide. This minimizes material waste, enables tight part nesting, and allows intricate details impossible with wider mechanical cutting methods.

Types of laser cutters

Laser cutters come in various types, each suited for different materials and applications. Let’s discover the primary types of laser cutters.

- CO2 lasers use a gas mixture (primarily carbon dioxide) as the laser medium, excited by an electrical discharge to produce the laser beam. They are ideal for non-metallic materials such as wood, acrylic, glass, paper, leather, and some plastics and are widely used in industries such as signage, engraving, textiles, and packaging.

- Neodymium lasers are a type of solid-state laser that uses neodymium (Nd) as the active lasing medium. This kind of laser is used in various medical procedures, industrial applications, defense, and security sectors.

- Fiber lasers generate the laser beam through a process of “seed” laser amplification in glass fibers. This beam is then directed to the cutting head through a flexible fiber optic cable. They are ideal for metals, including steel, aluminum, copper, brass, and other non-ferrous metals and commonly used in industries such as automotive, aerospace, electronics, and metal fabrication.

Cutting methods

Cutting methods can be broadly categorized into mechanical, thermal, and other specialized techniques. Here’s an overview of some common cutting methods.

- Vaporization cutting: this is a high-precision technique that involves using intense energy to vaporize material, creating a cut. The most common methods that utilize vaporization cutting are laser cutting and electron beam cutting. A focused laser beam is directed at the material, delivering high energy that heats and vaporizes the material at the cutting point. The vaporized material is blown away by a stream of gas, such as nitrogen or oxygen, to ensure a clean cut. The most applications involve metals, plastics, and composite.

- Melt and blow cutting is a technique used in manufacturing processes, particularly in the production of thin or delicate materials. It combines aspects of melting and blowing to achieve precise cutting. The material (often a plastic or glass) is heated to a molten state using a heat source. This can be done with a laser, an electric heater, or other methods that apply concentrated heat. Once the material reaches the melting point, a stream of gas (often air or an inert gas) is directed at the molten material. This blowing action helps in moving the molten material away from the cut area, clearing the path and ensuring a clean cut.

- Thermal stress cracking refers to the formation of cracks in materials due to differential thermal expansion and contraction. This phenomenon is particularly important in the context of materials subjected to varying temperatures or thermal gradients.

- Stealth dicing is a precision wafer dicing technique used to cut silicon wafers, especially in semiconductor manufacturing, where maintaining the integrity of the wafer and its components is crucial. Unlike traditional dicing methods, stealth dicing is designed to minimize damage to the wafer and improve yield.

- Reactive cutting is a technique used in various manufacturing and processing applications where a reactive material or chemical reaction is employed to perform the cutting. This method is often employed in situations where traditional cutting methods may not be effective or efficient.

How the Laser Cutting Process Works

Step 1: Design Creation: Everything begins digitally. Designers create cutting patterns using computer-aided design (CAD) software—anything from simple geometric shapes to intricate artistic designs. This digital approach means infinite design possibilities without physical templates or tooling.

Step 2: Laser Beam Generation: A laser source generates an intense beam of light. Different laser types exist—CO2 lasers using gas mixtures, fiber lasers using optical fibers, each suited to specific materials and applications.

Step 3: Beam Focusing: The laser beam travels through mirrors and lenses that direct and focus it to an incredibly small point—often smaller than a human hair’s width. This focusing concentrates enormous energy into a tiny area, creating temperatures exceeding 10,000°C at the focal point.

Step 4: Material Cutting: When this intensely focused beam contacts material, it heats that specific spot instantly to melting or vaporization temperature. The laser doesn’t physically touch the material—it’s a completely non-contact thermal process.

Step 5: Assist Gas Action: Compressed gas (oxygen, nitrogen, or air) flows through a nozzle surrounding the laser beam. This gas serves three critical functions: blowing away molten or vaporized material, preventing the cut from re-welding, and protecting expensive focusing lenses from debris and spatter.

Step 6: Precise Movement: Computer numerical control (CNC) systems move either the laser head or the material being cut, following programmed paths with incredible accuracy—typically within 0.1mm. The laser traces designs exactly as programmed, cutting shapes, holes, patterns, or text with perfect repeatability.

Materials Laser Cutting Can Process

Metals: Stainless steel, carbon steel, aluminum, brass, copper, titanium, and various alloys. Thickness ranges from thin foils through 30mm+ plate depending on laser power.

Plastics and Acrylics: Acrylic (Plexiglas), polycarbonate, ABS, polyethylene, PVC, and many polymers. Applications include signage, displays, protective covers, and consumer products.

Wood: Plywood, MDF, hardwoods, softwoods, and veneers. Perfect for furniture components, architectural models, crafts, decorative items, and custom woodwork.

Textiles: Fabrics, leather, felt, canvas, and technical textiles for fashion, upholstery, automotive interiors, and industrial applications.

Paper and Cardboard: Packaging, invitations, displays, models, and paper crafts benefit from precise cutting and intricate detail capability.

Composites: Carbon fiber, fiberglass, and hybrid materials used in aerospace, automotive, and sporting goods.

Key Advantages of Laser Cutting

Exceptional Precision: Tolerances within 0.1mm are routine. This accuracy enables complex assemblies, tight-fitting components, and applications where precision is critical.

Design Freedom: Cut any shape imaginable—complex curves, sharp angles, intricate patterns, tiny holes, delicate features. If you can design it digitally, lasers can cut it.

Speed and Efficiency: Automated operation processes parts far faster than manual cutting methods. What might take hours by hand completes in minutes with lasers.

Minimal Waste: Narrow kerf widths and sophisticated nesting software maximize material utilization—often 85-95% efficiency compared to 60-70% with traditional methods.

Clean, Quality Edges: Laser-cut edges are smooth, precise, and often require no secondary finishing. This saves labor and improves product appearance.

Versatility: Single machines process vastly different materials and thicknesses through software parameter changes alone—no physical tooling modifications needed.

Repeatability: Every part matches the first perfectly. This consistency is impossible with manual methods where operator skill, fatigue, and variations create inconsistencies.

No Tool Maintenance: Lasers never dull, chip, or wear like mechanical cutting tools. This eliminates blade replacement costs and maintains consistent quality indefinitely.

Common Laser Cutting Applications

Manufacturing: Metal parts for electronics, machinery, vehicles, appliances, and industrial equipment. Laser cutting is fundamental to modern manufacturing.

Signage: Letters, logos, displays, and decorative elements from metals, acrylics, woods, and various materials.

Automotive: Body panels, brackets, exhaust components, interior trim, and countless parts throughout vehicles.

Aerospace: Aircraft components requiring extreme precision, lightweight design, and rigorous quality standards.

Architecture: Decorative panels, railings, facades, and artistic elements that define contemporary building design.

Fashion and Accessories: Intricate fabric patterns, leather goods, jewelry components, and fashion details.

Prototyping: Product development across all industries relies on laser cutting for rapid, economical prototype creation.

Custom Products: Personalized gifts, awards, trophies, signage, and unique items where customization adds value.

Art and Crafts: Artists and makers create sculptures, decorative items, models, and creative works leveraging laser precision.

Laser cutting design software

Laser cutting design software is crucial for creating files that guide the laser cutter in producing precise and accurate cuts and engravings. The choice of software depends on the complexity of the design, budget, and specific needs of the project. Whether you need detailed vector graphics, technical drawings, or integrated machine control, there’s a range of tools available to suit various applications in laser cutting.

3D Design

When working with 3D design for laser cutting, the process involves creating designs that are often intended to be cut from 2D slices or components, which can then be assembled into 3D structures. Laser cutting is inherently a 2D process, but it can be used to fabricate 3D objects through techniques like slicing and assembling. Software like Autodesk Fusion 360, Rhino, and Blender offer robust tools for 3D modeling and preparing designs for laser cutting. For simpler needs or beginners, tools like Tinkercad and SketchUp provide user-friendly interfaces.

Vector Cutting

Vector cutting is a technique used in laser cutting and other cutting processes where the design is based on vector graphics. Unlike raster graphics, which are pixel-based, vector graphics are made up of paths defined by mathematical equations. This allows for precise and scalable designs without loss of quality. By creating designs in vector-based software such as Adobe Illustrator, CorelDRAW, or Inkscape, and preparing files for cutting machines, you can achieve detailed and scalable results.

Laser Rastering

Laser rastering is a technique used in laser cutting and engraving where a laser beam scans across the material to produce detailed, high-resolution images or patterns. Unlike vector cutting, which follows defined paths, rastering works by moving the laser across the surface in a grid-like pattern, like how a printer works. Rastering involves scanning the laser beam over the material in a back-and-forth motion to engrave or mark the surface. Vector cutting, on the other hand, involves cutting along specific paths defined by the design.

Related technologies

- Other 2D CNC Machines

In addition to laser cutting, several other 2D CNC machines are used for various types of cutting and machining tasks. We can mention for instance waterjet cutters (they use a high-pressure stream of water mixed with abrasive particles to cut through materials. The abrasive garnet particles increase cutting efficiency; CNC Laser Cutters (they are used for a high-powered laser beam to cut or engrave materials and operate on a 2D plane, with the laser moving along predefined paths). This technology is suitable for cutting materials like wood, acrylic, paper, and thin laser cut metals.

- 3D Printers

3D printers are versatile machines that create three-dimensional objects by adding material layer by layer according to a digital design. They are used in various industries, including manufacturing, healthcare, automotive, and consumer products. Combining 3D printing with metal cutting or laser technology can offer versatile and efficient solutions for various applications.

- CNC Routers

CNC routers use a rotating cutting tool or bit to remove material from a workpiece. They operate on a similar principle to traditional routers but are controlled by a computer and are ideal for cutting, engraving, and shaping materials such as wood, plastics, and some metals.

Conclusion

Laser cutting is a precise, versatile, efficient manufacturing process using focused light energy to cut materials following computer-controlled paths. It’s transformed industries by enabling designs and production methods impossible with traditional cutting, while delivering quality, speed, and economy that competitive manufacturing demands. Whether cutting intricate jewelry components or massive steel plates, laser technology provides capabilities that continue expanding manufacturing possibilities worldwide. Understanding what laser cutting is and how it works opens your awareness to opportunities this remarkable technology might offer your projects, products, or business.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.