Laser Knowledge

What are the Components of A Fiber Laser Cutting Machine?

A fiber laser cutting machine is a laser cutting machine with a fiber laser as the light source. Fiber laser cutting machines consist of different components. Different internal components and configurations result in different machining results. Therefore, it is best for us to know more about the various parts of the fiber laser cutting machine before buying. Different component configurations also affect the price. Therefore, IGOLDENLASER recommends: buyers must understand the components of the fiber laser cutting machine before purchasing.

Working principle of fiber laser cutting machine

Fiber lasers output high-energy laser beams. The light is concentrated on the surface of the workpiece, and the irradiated area on the workpiece is instantly melted and vaporized. The machine realizes automatic cutting by moving the spot position by numerical control.

The main components of the fiber laser cutting machine

1. Fiber Laser

Laser is the core “power source” of the fiber laser cutting machine. Just like a car engine, it is also an expensive component in a fiber laser cutting machine. At present, there are IPG, ROFIN, RAYCUS, and other fiber lasers on the market.

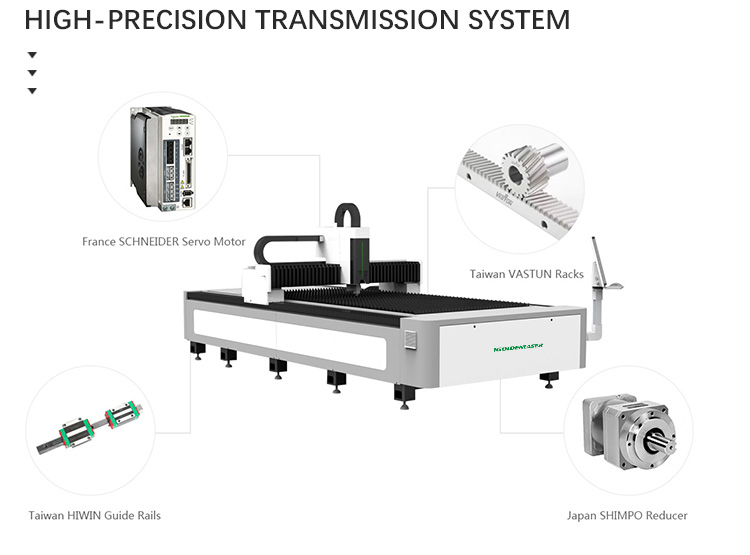

2. Motor

The motor of the fiber laser cutting machine is the core component of the motion system. The performance of the motor directly affects the effect of the production efficiency. At present, the commonly used motors are stepper motors and servo motors. Buyers can choose from them according to the product type.

A. Stepper motor:

The stepper motor has a fast start-up speed and a sensitive response. It is suitable for less demanding cuts. There are many brands of stepper motors with different performances.

B. Servo motor:

It has stable performance and fast cutting speed. The processed product has smooth edges. Therefore, it is suitable for industries with high cutting requirements.

3. Fiber laser cutting head

The fiber laser cutting head is a laser output device. It consists of a nozzle, a focusing lens, and a focus tracking system. The cutting head of the fiber laser cutting machine will follow the set cutting trajectory. But the operator has to adjust the height of the laser cutting head according to the material, thickness, and cutting method.

4. Laser lens

Laser lenses are mostly used in the entire fiber laser cutting equipment. Many optical devices contain laser lenses. Different lenses have different functions. Such as total reflection lens, half reflection lens, focusing lens, etc. The quality of the lens directly affects the output power of the laser, and also affects the performance of the fiber laser machine.

5. Host workbench

The bed, beam, worktable, and Z-axis system of the fiber laser cutting machine are collectively referred to as the host. When making a cut, the operator first places the workpiece on the bed. Then he used a servo motor to drive the beam to control the movement of the Z axis. Users can adjust the parameters according to their needs.

6. The frame of the laser machine

Fiber laser cutting machines have very high requirements for mechanical stability. At present, the main racks are gantry type, cantilever type, beam type, and so on. Different racks have different functions. For example, the beam frame is mainly used for material cutting by large manufacturers. There are also domain-specific models. For example, 3D fiber laser cutting is mainly used in the automotive industry.

7. Chiller

The chiller is the cooling device of the fiber laser cutting machine. It can quickly cool equipment such as lasers, spindles, etc. At present, chillers are equipped with switch control input and output. And it has functions such as high-temperature and low-temperature alarms. Therefore, its performance is more stable.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.