Laser Knowledge

Single vs Dual Pendulum Laser Welding Heads: Which One Should You Choose?

Laser welding has become one of the fastest-growing technologies in metal processing, offering high precision, low heat distortion, and excellent weld quality. As laser welding heads evolve, two major technologies have emerged as the industry standard: Single Pendulum (Single Swing) and Double Pendulum (Dual Swing) laser welding.

In 2025, choosing the right swing mode is essential for manufacturers who want to optimize efficiency, improve weld quality, and adapt to different metal types. This article explains the differences between single pendulum and double pendulum laser welding, including working principles, advantages, applications, and how to choose the right system for your production.

Examples are based on real industrial machines like the iGOLDENCNC Pendulum Laser Welding Machine and iGOLDENCNC Double Pendulum Wobble Laser Welding Head.

What Is Pendulum Laser Welding?

There are two types of oscillation modes in galvanometer-based laser welding:

- Single-pendulum: The laser beam oscillates in one direction (typically X or Y axis), controlled by a single galvanometer motor.

- Dual-pendulum: Two galvanometer motors control the beam in both X and Y directions, allowing for more complex oscillation patterns and a wider range of welding applications.

In handheld laser welding, embedded controllers are commonly used as the control system. Depending on whether the galvanometer uses a single or dual-axis motor for beam steering, handheld laser welding systems are categorized into single-axis control systems and dual-axis control systems.

-

Linear swing

-

Circular swing

-

Figure-8 swing

-

Elliptical swing

This oscillation helps distribute heat more evenly and increases the tolerance for gaps in the workpiece.

| Welding system | ||

| Content | Single Pendulum | Double Pendulum |

| Supply voltage | 1500W/2000W: Single-phase 220V±10%, 50/60Hz AC 3000W: Three-phase 380V±10%, 50/60Hz AC |

|

| Output method | Continuous light | |

| Power | ≤3000W | |

| Language | 13 languages: Simplified, Traditional, English, Japanese, Korean, German, Portuguese, Spanish, French, Russian, Turkish, Arabic, Polish | |

| Operating mode | Straight line mode | —、○、∞、 |

| Laser power adjustment | 10%-100% continuous gradient adjustable | |

| Laser frequency adjustment | 1kHz-30kHz continuous gradient adjustable | |

| Collimating focal length | 50mm | |

| Focal length | 200mm | |

| Range of focus adjustment | -10mm ~ 10mm | |

| Spot adjustment range | 0-8mm | 0-5mm |

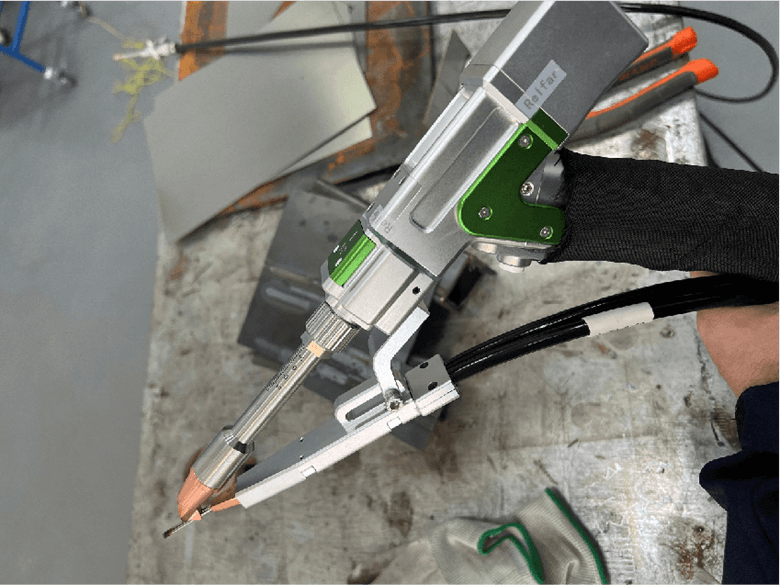

| Welding head picture | ||

| Cleaning head weight | 0.96KG | 0.8KG |

| Vibration lens material | quartz | |

| Mirror material | quartz | |

| Field lens material | quartz | |

| Screen | Cabinet standard 7 inches | |

| Cable length | 10 m (optional 15/20 m) | |

Industry Applications

Single Pendulum Welding Applications

-

Stainless steel cabinets

-

Sheet metal fabrication

-

Metal doors and windows

-

Railings and frames

-

Chemical equipment

-

Food machinery

Double Pendulum Welding Applications

-

Automotive components

-

Aluminum alloy structures

-

Battery pack / EV components

-

Aerospace parts

-

Robots and equipment frames

-

High-precision industrial products

Single-Pendulum Welding System

The single swing laser welder features a simple structure, easy operation, and lower equipment cost, making it widely used in conventional sheet metal processing. However, it has a limited oscillation angle and lower directional control precision, which restricts its effectiveness in more complex welding scenarios.

Double-Pendulum Laser Welding System

In contrast, the double swing laser welding machine enables flexible beam steering through two-axis oscillation, significantly enhancing welding flexibility and efficiency. This system excels in handling wide gaps, dissimilar materials, and complex structures, delivering higher-quality welds. Due to its more complex design—featuring two galvanometer motors and dual mirrors—the cost is comparatively higher.

Advantages of Double Pendulum Laser Welding

1. Larger weld seam width

Ideal for parts with inconsistent fit-up or slightly larger assembly gaps.

2. Better weld seam appearance

The oscillation smooths the edges and reduces heat accumulation.

3. More stable performance on aluminum and reflective metals

Aluminum welds can easily create pores and cracks; double pendulum helps avoid this.

4. Lower risk of burn-through

Heat spreads more evenly across the weld seam.

5. Professional-grade welding for demanding applications

Especially important in industries needing high-quality seams.

Limitations of Double Pendulum Laser Welding

-

Slightly lower penetration due to wider energy distribution

-

More expensive equipment

-

More complex structure → higher maintenance requirements

-

Requires better parameter tuning

How to Choose the Single Pendulum and Double Pendulum Handheld Laser Welding Machine

When selecting a single-pendulum or double-pendulum handheld laser welding system, it is essential to evaluate the following key factors:

1. Welding Requirements

Consider the specific welding tasks—such as seam shape, gap width, and material type.

For narrow, simple welds on standard sheet metal, a single-pendulum system is typically sufficient.

For wide gaps, dissimilar materials, or complex geometries, a double-pendulum system offers superior control and weld quality.

2. Budget Considerations

Double-pendulum systems are more technologically advanced and generally come at a higher price.

If operating under a limited budget, a single-pendulum system may be a more cost-effective choice—though it may involve trade-offs in performance and versatility.

3. Ease of Operation

Single-pendulum systems are usually easier for beginners or non-specialist operators to learn and use.

However, with modern user interfaces and improved training support, double-pendulum systems are becoming increasingly user-friendly and accessible, even for less experienced personnel.

| Type | Single pendulum | Double pendulum |

| Applicability | Simple & repetitive welding tasks; low requirements on penetration depth and strength. | Complex parts, non-standard shapes; welding of dissimilar materials, especially highly reflective materials such as aluminum and copper. |

| Efficiency | Medium efficiency | Efficient and more suitable for complex shapes |

| Technical skills | low requirements, easy operation | Senior and experienced welders are needed |

| Cost | low equipment price and maintenance costs | The equipment structure is more complex and the cost is higher |

Six Typical Double-Swing Laser Welding Modes

Using double-swing laser welding is highly advantageous. The machine offers six distinct swinging modes to suit various welding needs:

- Linear Swing: Enhances weld penetration and seam uniformity, ideal for improving stability in standard welds.

- Circular Swing: Suitable for small round components or curved weld paths, providing consistent energy distribution along circular geometries.

- Figure-8 Swing: Ideal for deep penetration welding or dynamic heat control, ensuring stable molten pool behavior and reducing thermal stress.

- Double-Arc Swing: Enhances fusion on both sides of the seam, especially useful for wider joints or dissimilar thickness connections.

- Triangle Swing: Optimized for beveled edges or angled joints, facilitating smooth material bridging across varying seam profiles.

- Double-Triangle Swing: Best suited for irregular or offset seams, offering precise control of heat input across non-uniform welding paths.

Future Technology Trends

Laser welding head technology continues evolving rapidly. Emerging developments include integration of artificial intelligence for real-time pattern optimization, enhanced monitoring systems providing closed-loop process control, and hybrid systems combining pendulum motion with additional beam shaping technologies.

Industry 4.0 connectivity enables remote monitoring, predictive maintenance, and continuous process improvement through data analytics. These smart welding systems learn from production data, automatically refining parameters to maintain optimal performance.

Conclusion

The choice between single and dual pendulum laser welding heads depends fundamentally on application requirements, quality expectations, and budget constraints. Single pendulum systems deliver substantial benefits over static beam welding at moderate cost, making them ideal for most mainstream manufacturing applications. Their proven performance, reliability, and cost-effectiveness suit high-volume production where straightforward joints and common materials predominate.

Dual pendulum technology represents the premium solution for demanding applications where superior gap bridging, enhanced weld quality, and advanced process control justify increased investment. Industries with stringent quality requirements, challenging materials, or complex geometries benefit most from dual pendulum capabilities.

Manufacturers should conduct thorough application analysis, including joint design evaluation, material testing, and cost-benefit assessment before selecting pendulum welding technology. Many suppliers offer demonstration testing, enabling real-world validation before final equipment decisions. Understanding the distinct advantages and limitations of each technology ensures optimal equipment selection aligned with specific manufacturing needs and business objectives.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.