Buyer Guide

Qr Code Laser Marking Machine

laser can act on the surface of the material with a very fine beam, the finest line width can reach 0.05mm, which creates a wide application space for precision processing and increased anti-counterfeiting function. Laser marking can meet the need to print large amounts of data on very small plastic parts. For example, it can print 2D barcodes that require greater precision and clarity, which is more competitive in the market compared to embossing or jet marking methods. Accurate multiple two-dimensional code is very important to ensure the integrity of the two-dimensional code printing to be more effective.

Qr Code Laser Marking Machine

Laser marking technology is widely used for marking QR codes on various materials due to its precision, permanence, and versatility. Here are some key aspects of laser marking technology as it relates to QR codes:

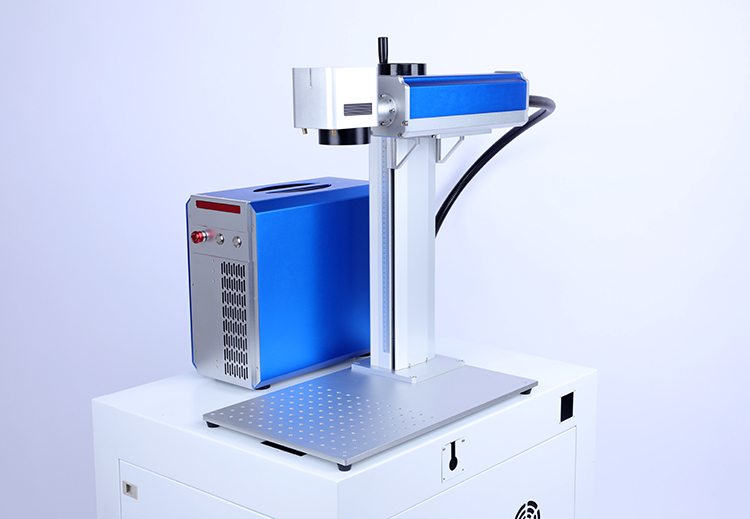

- Laser Types: Laser marking can be performed using different types of lasers, including fiber lasers, CO2 lasers, and solid-state lasers. Fiber lasers are commonly used for marking QR codes due to their high beam quality, flexibility, and efficiency.

- High Precision: Laser marking offers high precision and accuracy, allowing for the creation of small, intricate QR code designs with fine details. This precision ensures that the QR code remains scannable and readable.

- Durability: Laser-marked QR codes are highly durable and resistant to wear, chemicals, and environmental factors. This makes them suitable for a wide range of applications, including industrial and outdoor use.

- Versatility: Laser marking can be performed on various materials, including metals, plastics, ceramics, glass, and more. This versatility allows QR codes to be marked on a wide range of products and surfaces.

- Customizability: Laser marking technology enables the customization of QR codes by adjusting parameters such as size, density, and design. This allows for the incorporation of branding elements, logos, or additional information within the QR code design.

- High-Speed Marking: Laser marking can be performed at high speeds, making it suitable for marking large quantities of products in industrial settings. The marking speed depends on factors such as the laser power, material type, and complexity of the QR code design.

- Non-Contact Process: Laser marking is a non-contact process, which means that the material being marked is not physically touched or damaged during the marking process. This is particularly important when working with delicate surfaces or materials.

- Eco-Friendly: Laser marking is considered an environmentally friendly marking method since it does not involve the use of inks, solvents, or chemicals. It produces minimal waste and does not generate harmful fumes or residues.

- Integration with Automation: Laser marking technology can be easily integrated into automated production lines, allowing for efficient and seamless marking of QR codes on a large scale. Overall, laser marking technology provides a reliable and efficient method for permanently marking QR codes on various materials, offering durability, customization options, and high-quality results.

What Is A Laser Marking Machine Used For?

Laser marking machine are the most common engraving tool kits used in various industries of embroidery, brand processing, packaging and printing, custom credit cards, advertisement decoration, architectural models, metal fabrication, woodworking, custom smartphones & laptops, molds, crafts, leathers, shoes, toys, fablabs & education, medical technology, rubber stamps, watches, architectural models, packaging design, automotive industry, mechanical engineering, awards & trophies, signs & displays, signage, giveaways, electronics industry, data plates, personalized jewelry maker, ball bearing, barcode serial numbers, and more. With the laser beam engraving system, you can engrave different designs on different substrates. The laser beam will make the surface to vaporize. It is ideal for someone who wants to customize or personalize something.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.