Laser Knowledge

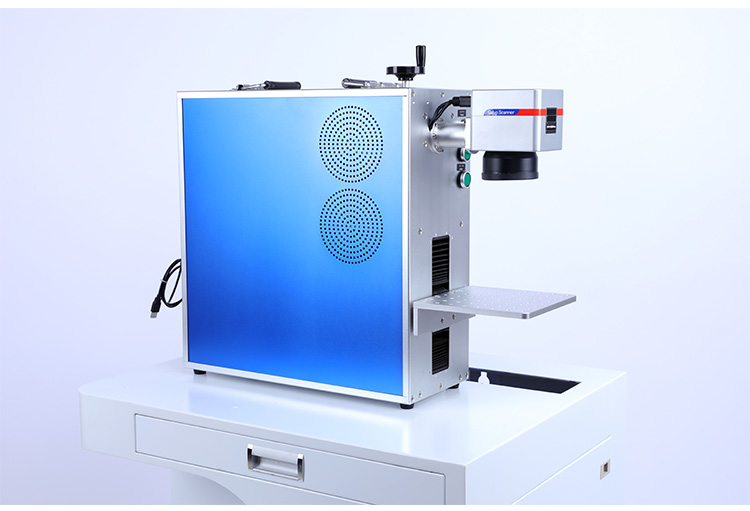

Portable Fiber Laser Metal Engraving Machine

Portable laser marking machine is a type of compact laser engraving system with JPT fiber laser source, which is easy to place and move. It adopts a unique integrated and fully built-in design, highly integrated optical, electronic and mechanical components, and a fully air-cooled design without external circulation cooling devices. It is an upgraded version of the desktop laser engraver. The principle is to use a laser beam to make permanent marks on the surface of various materials. Portable laser engraving machine has the features of small size (air cooling without water cooling device), good laser beam quality (base mode), and maintenance-free.

Laser Engraver Machine

Affordable fiber laser engraver for color marking is designed to etch black, white, grey, and colors on metals of stainless steel, titanium, and chromium. Now the best rotary color laser engraving machine for sale at cost price.With their ability to create intricate designs on various metal surfaces, these machines have become essential tools in industries ranging from jewelry making to manufacturing. Their non-contact process, speed, and customization options make them highly sought-after devices in today’s modern world.

A fiber laser engraver is an automatic marking system that uses a focused fiber laser beam to etch the surface of a substrate, changing its properties and appearance to create permanent marks. Fiber laser generators are available from well-known brands such as IPG, Raycus, JPT, and Max. 20W, 30W, 50W, 60W and 100W power options are available for engravings of various thicknesses. A fiber laser marking machine features with high speed, high quality, high precision, no pollution, safety, convenient operation, maintenance-free, and low cost.

A fiber laser etcher can engrave permanent marks including letters, numbers, signs, logos, patterns, pictures on 2D/3D surfaces of bare metals and coated metals including carbon steel, stainless steel, galvanized steel, aluminum, brass, copper, silver, gold, titanium, iron and alloy, as well as fiberglass and plastics including PVC, PLT, PS, ABS, PBT. With a higher power, it can do relief engraving and deep engraving on metals. With a rotary attachment, it can do rotary engraving on rings, cups, and cylinders. With a belt conveyor, it can do marking on the fly in industrial assembly line manufacturing. In addition, with a MOPA laser source, it can do color engraving on stainless steel, chromium and titanium.

Metal Engraving Machine Key Features:

Laser Technology: The laser metal engraving machine employs a powerful laser beam to perform precise and controlled engraving on metal surfaces. The laser beam can be focused to a very fine point, enabling intricate detailing and high-resolution engraving.

Versatility: The machine is compatible with a wide range of metals, including stainless steel, aluminum, brass, copper, titanium, and more. It can engrave on flat, curved, or irregular surfaces, making it suitable for various applications such as jewelry engraving, industrial part marking, signage production, personalized gift creation, and more.

High Precision: The laser metal engraving machine ensures exceptional precision and accuracy in engraving. It can create intricate designs with sharp edges, fine lines, and smooth curves, resulting in professional-quality engravings.

Customization and Flexibility: With a laser metal engraving machine, users have the freedom to customize their designs according to their specific requirements. The machine can engrave different fonts, graphics, logos, and serial numbers, allowing for personalization and branding opportunities.

Non-contact Engraving: Unlike traditional engraving methods that involve physical contact with the material, laser metal engraving is a non-contact process. The laser beam heats and vaporizes the metal surface, creating permanent and durable engravings without causing damage or deformation to the material.

Speed and Efficiency: Laser metal engraving machines are known for their high-speed engraving capabilities. They can complete complex engravings in a fraction of the time required by traditional methods, enhancing productivity and reducing production costs.

User-Friendly Interface: Most laser metal engraving machines are equipped with user-friendly interfaces and software. This allows operators to easily design and control the engraving process, adjust parameters, preview designs, and ensure optimal results.

Portable Laser Engraver Applications:

Laser metal engraving machines find applications in various industries and sectors, including:

Jewelry Making: The machine is widely used in the jewelry industry for engraving intricate designs, patterns, and text on precious metals like gold, silver, and platinum.

Industrial Part Marking: It is utilized for permanent marking of part numbers, serial numbers, barcodes, and logos on metal components, ensuring traceability and product identification.

Signage and Nameplate Production: Laser metal engraving machines enable the creation of high-quality signs, nameplates, and plaques for indoor and outdoor applications, including office buildings, hotels, and architectural projects.

Personalized Gifts and Awards: The machine is employed to engrave personalized messages, names, dates, or photos on metal gifts and awards, adding a special touch and sentimental value.

Manufacturing and Automotive: Laser metal engraving is utilized for marking and branding metal products, tools, and automotive parts for identification, quality control, and anti-counterfeiting purposes.

How Does A Laser Engraving Machine Work?

Laser engraving is based on computer numerical control technology. First, you need to make a design of file, then, open the file through software, and start CNC programing, the engraver will start working after the control system received the control command. The laser beam is reflected through mirrors, the focal point downward through lens, where the heat is most intense. Thus, the beam starts impinging on the material, the material will burn or evaporate, and the color will change as well, and make a contrast. After a while, a complete engraved project will be finished.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.