Buyer Guide

Laser Etching Machine: Complete Guide for Marking and Engraving

Laser etching creates patterns and designs on a material by melting its surface with a laser beam, making it one of the most precise and versatile marking technologies available today. Laser etching machines are more popular due to their marking impression in OEM’s and other manufacturing industries, offering unmatched precision, efficiency, and flexibility for diverse applications.

In this generation, using a laser engraver will provide high precision, versatility, and efficiency, making it an ideal choice for you to create detailed and durable engravings on a wide range of materials. This comprehensive guide explores everything you need to know about laser etching machines in 2025.

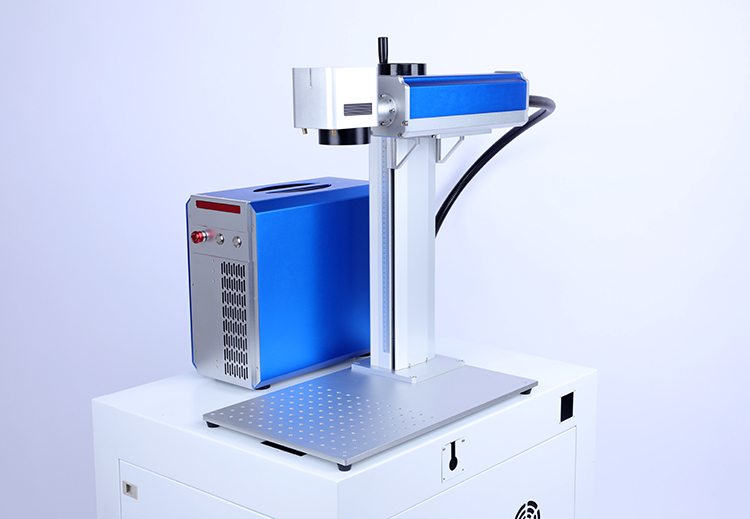

Laser Etching Machine

A laser etching machine is a high-precision device that uses focused laser beams to mark, engrave, or etch surfaces permanently. It’s widely used for metal, plastic, glass, wood, and stone—ideal for both industrial marking (logos, barcodes, serial numbers) and custom design (jewelry, gifts, signage).

Common Applications

-

Metal Products: Serial numbers, barcodes, logos, QR codes

-

Jewelry: Names, designs, personalization

-

Industrial Parts: Tool identification, traceability

-

Wood & Acrylic Signs: Custom logos, artwork, lettering

-

Glass & Leather Gifts: Decorative engraving

Recommended iGOLDENCNC Models

-

iGL-FL20 Fiber Laser Etching Machine – compact, affordable for metals

-

iGL-CO2 60W CO₂ Laser Etcher – ideal for wood, acrylic, and signage

-

iGL-UV3 UV Laser Marking Machine – delicate, high-resolution plastic/glass marking

-

iGL-MOPA Fiber Laser – color etching on stainless steel & aluminum

Understanding Laser Etching Technology

Laser etching is a precise manufacturing process that uses focused laser beams to remove material from surfaces, creating permanent marks, patterns, or designs. Unlike traditional mechanical engraving methods, laser etching offers contactless processing, eliminating tool wear and enabling consistent results across various materials.

How Laser Etching Works

The laser etching process involves directing a highly concentrated beam of light onto the material surface. The intense heat generated by the laser beam melts or vaporizes the material at the focal point, creating precise etched patterns with minimal heat-affected zones.

Benefits of Laser Etching Technology

Precision and Accuracy: Modern laser etching machines deliver exceptional precision with tolerances measured in microns, enabling fine detail work impossible with traditional methods.

Versatility: Laser systems can process metals, plastics, ceramics, glass, wood, and composites, making them suitable for diverse industrial applications.

Speed and Efficiency: High-Speed Engraving: Laser machines like the LP5 can engrave at speeds of up to 10,000mm/s, completing a complex pattern in just two minutes—significantly faster than mechanical methods.

Contactless Processing: No physical contact between tool and workpiece eliminates wear and reduces maintenance requirements.

Types of Laser Etching Machines

Understanding the different types of lasers used in engraving is crucial. Here’s a breakdown of the main types, they are CO2 Lasers, Fiber lasers, UV lasers, and diode lasers. Each laser type offers unique benefits and specific material compatibility.

Fiber Laser Etching Machines

Fiber laser systems excel at processing metals and hard materials, making them the preferred choice for industrial marking applications.

Key Advantages:

- Exceptional beam quality with M² values near 1.0

- High power density for deep etching capabilities

- Low maintenance requirements

- Excellent electrical efficiency

- Superior performance on reflective metals

Optimal Materials:

- Stainless steel, aluminum, brass, copper

- Tool steels and hardened metals

- Anodized surfaces

- Some plastics and ceramics

Applications:

- Part identification and traceability

- Serial number marking

- Logo and branding applications

- Medical device marking

CO2 Laser Etching Machines

CO2 lasers are quickly becoming popular due to the degree of accuracy, speed, and flexibility offered by the laser engraver. These systems work exceptionally well with organic materials and certain plastics.

Key Advantages:

- Excellent for organic materials

- High cutting speeds

- Clean edge quality

- Cost-effective operation

- Wide material compatibility

Optimal Materials:

- Wood, paper, cardboard

- Acrylic and many plastics

- Leather and fabric

- Glass (surface etching)

- Rubber materials

Applications:

- Signage and architectural elements

- Promotional products

- Packaging and labeling

- Artistic and decorative items

UV Laser Etching Machines

UV laser systems provide “cold” processing with minimal heat effects, making them ideal for delicate materials and precision applications.

Key Advantages:

- Minimal heat-affected zones

- Exceptional precision capabilities

- Suitable for heat-sensitive materials

- High-quality surface finishes

- Precise micro-machining capabilities

Optimal Materials:

- Electronics and circuit boards

- Medical devices and components

- Glass and crystal materials

- Flexible circuits

- Thin films and coatings

Applications:

- Electronics manufacturing

- Medical device production

- Precision component marking

- Research and development

Diode Laser Etching Machines

Diode lasers offer compact, cost-effective solutions for light-duty etching applications and hobbyist use.

Key Advantages:

- Compact and portable design

- Low initial investment

- Simple operation and maintenance

- Energy efficient

- Suitable for small-scale production

Optimal Materials:

- Light wood etching

- Paper and cardboard

- Some plastics and acrylics

- Leather and fabric

Applications:

- Hobbyist and DIY projects

- Small business applications

- Educational and training use

- Prototyping and development

Advanced Laser Etching Features

MOPA Fiber Laser Technology

This 60W Mopa fiber laser can produce black markings on aluminium and colour engraving on stainless steel. MOPA (Master Oscillator Power Amplifier) technology provides enhanced control over pulse parameters, enabling specialized marking effects.

MOPA Advantages:

- Offers adjustable pulses for varied etching outcomes

- Color marking capabilities on stainless steel

- Black marking on aluminum

- Fine-tuned pulse control

- Enhanced material versatility

3D Deep Laser Etching

2025 top rated 3D laser engraving machine with fiber laser source is used for deep etching on 3D surface of metal & nonmetal with enclosed structure for safety.

3D Etching Capabilities:

- Multi-axis processing for complex geometries

- Deep etching on curved surfaces

- Advanced software integration

- Enhanced safety features

- Precise depth control

Material-Specific Applications

Metal Etching Applications

Stainless Steel: Professional systems can create high-contrast markings, color effects, and deep etching on stainless steel surfaces for medical, food service, and industrial applications.

Aluminum Processing: Each type of aluminum material offers unique characteristics and engraving results, making it essential to choose the most suitable material based on the desired outcome and application requirements.

Industrial Marking: Part traceability, serial numbers, barcodes, and quality marks for automotive, aerospace, and manufacturing industries.

Plastic and Polymer Processing

Modern laser etching systems handle various plastics including ABS, acrylic, polycarbonate, and engineering plastics with precise control over marking depth and appearance.

Electronic Component Marking

UV and fiber lasers excel at marking electronic components, circuit boards, and delicate electronic assemblies without thermal damage.

Selection Criteria for Laser Etching Machines

Application Requirements Assessment

Material Compatibility: Identify primary materials for processing and select appropriate laser technology based on wavelength and power requirements.

Production Volume: Consider daily production requirements, cycle times, and automation needs to select appropriate system capacity.

Precision Requirements: Evaluate marking resolution, depth control, and positioning accuracy requirements for your applications.

Technical Specifications

Power Requirements: The machine should have the ability to make deep etchings on materials such as copper or iron. Select appropriate laser power based on material thickness and processing speed requirements.

Beam Quality: Consider M² values, spot size capabilities, and beam stability for precision applications.

Software Integration: Evaluate CAD/CAM compatibility, file format support, and automation capabilities.

Business Applications and Market Opportunities

Industrial Manufacturing

Traceability Solutions: MECCO provides laser etching and laser engraving machines to help manufacturers improve part traceability and increase efficiency.

Quality Control: Permanent marking for quality assurance, batch tracking, and regulatory compliance.

Custom Manufacturing Services

Growing demand for personalized products creates opportunities for custom etching services across various industries.

Medical Device Manufacturing

Precise marking capabilities make laser etching essential for medical device identification and traceability requirements.

Future Trends and Technology Development

Automation Integration

Advanced systems incorporate robotic handling, vision systems, and automated quality inspection for high-volume production environments.

Software Advancements

AI-assisted parameter optimization, predictive maintenance, and enhanced user interfaces improve productivity and ease of use.

Sustainable Manufacturing

Energy-efficient designs and reduced material waste align with environmental sustainability goals while improving operational costs.

Conclusion

As you explore laser etching further, you will find that there are applications that require precise, fast, effective and unique marking results. A good machine is essential to achieve different marking results on different materials.

Laser etching machines represent essential technology for modern manufacturing, offering unparalleled precision, versatility, and efficiency across diverse applications. Whether you’re in industrial manufacturing, custom services, or specialized production, the right laser etching system provides the foundation for quality, productivity, and competitive advantage.

Variety of laser machines is there to provide etching solutions with high efficiency and precision. The key to successful implementation lies in understanding your specific requirements, selecting appropriate technology, and maintaining focus on quality and safety throughout your operations.

As laser technology continues advancing, these systems become increasingly accessible and capable, making laser etching an excellent investment for businesses seeking to enhance their marking and identification capabilities while meeting demanding quality and productivity requirements.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.