Laser Knowledge

Laser Cut Polycarbonate

Laser cutting polycarbonate can be a challenging process, but with the right equipment and settings, it can be done effectively. Polycarbonate is a durable, impact-resistant plastic often used in various applications such as machine guards, signage, and enclosures.

Polycarbonate is a transparent thermoplastic material known for its exceptional strength, durability, and optical clarity. It is widely used in industries such as automotive, aerospace, electronics, and construction due to its excellent impact resistance and high heat resistance. Polycarbonate is also lightweight, making it an ideal choice for applications where weight reduction is crucial.

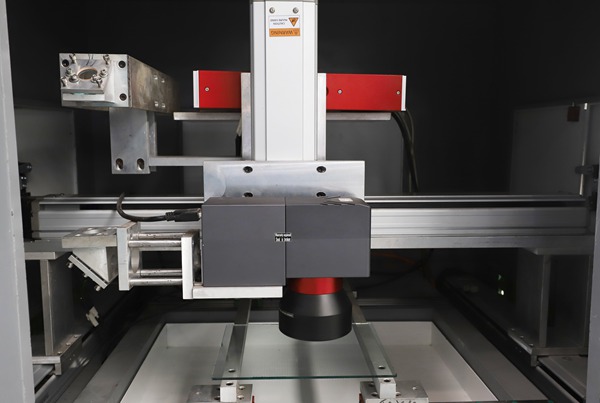

Polycarbonate Laser Cut Machine

Polycarbonate laser cutting machines are specifically designed to cut through polycarbonate sheets with precision and accuracy. These machines utilize high-powered lasers to create clean and smooth cuts, allowing for the creation of intricate designs and shapes. Polycarbonate laser cutting machines are equipped with advanced technology and features that optimize the cutting process and ensure optimal results.

CO2 Laser Cutting Machine

Thin sheets of polycarbonate can be cut with our CO2 laser systems, but the material tends to discolor when heated by the laser beam. The thinner the sheet you are cutting, the better the cutting results you will obtain. If you would like us to test your sheet of polycarbonate, please contact our Applications Lab.

Plexiglass Laser Cutting Machine

Features and Capabilities

1. High-Powered Lasers

Polycarbonate laser cutting machines are equipped with high-powered lasers that deliver intense beams of light. These lasers can generate enough heat to melt and vaporize the polycarbonate material, resulting in precise and clean cuts. The power of the laser can be adjusted based on the thickness and type of polycarbonate being cut, allowing for versatility in cutting various materials.

2. Precision and Accuracy

One of the key advantages of polycarbonate laser cutting machines is their ability to provide precise and accurate cuts. The focused laser beam allows for intricate details and complex shapes to be cut with ease. The machines are equipped with computer-controlled systems that ensure consistent accuracy and repeatability, making them ideal for industries that require tight tolerances.

3. Automated Operation

Polycarbonate laser cutting machines are designed for efficiency and productivity. They feature automated operation capabilities, allowing for continuous cutting without the need for constant manual intervention. The machines can be programmed with digital designs created using computer-aided design (CAD) software, eliminating the need for manual tracing or cutting.

4. Versatility in Cutting

Polycarbonate laser cutting machines offer versatility in cutting various shapes and sizes. They can cut straight lines, curves, angles, and even intricate patterns. The machines can also perform 3D cutting, allowing for the creation of three-dimensional structures and designs. This versatility opens up a world of possibilities for designers and manufacturers.

5. Minimal Post-Processing

The precision and cleanliness of cuts produced by polycarbonate laser cutting machines result in minimal post-processing requirements. Unlike traditional cutting methods, laser cutting eliminates the need for additional sanding, polishing, or finishing. This saves time and reduces costs, making the manufacturing process more efficient.

The Laser Cutting Process

Laser cutting machine is a non-contact cutting method that utilizes a high-powered laser beam to cut through materials with precision and accuracy. When it comes to polycarbonate, the laser cutting process involves the following steps:

- Material Preparation: The polycarbonate sheet is prepared by ensuring it is clean and free from any debris or contaminants. This ensures a smooth cutting process and prevents any damage to the laser equipment.

- Design Creation: A digital design is created using computer-aided design (CAD) software. The design specifies the desired shape, dimensions, and details of the cut.

- Laser Setup: The laser cutting machine is set up with the appropriate power and speed settings based on the thickness and type of polycarbonate being cut. The focal length of the laser beam is also adjusted to ensure optimal cutting results.

- Cutting Process: The laser beam is directed onto the polycarbonate sheet, following the path specified in the digital design. The intense heat generated by the laser beam melts and vaporizes the material, creating a clean and precise cut. The laser cutting machine’s computer-controlled system ensures accuracy and repeatability throughout the cutting process.

- Finishing Touches: Once the cutting process is complete, the polycarbonate piece may require some finishing touches, such as removing any burrs or sharp edges.

Advantages of Laser Cut Polycarbonate

1. Precision and Accuracy

Laser cutting offers unparalleled precision and accuracy when working with polycarbonate. The focused laser beam allows for intricate and detailed cuts, enabling the creation of complex shapes and designs with ease. This level of precision is especially beneficial for industries where tight tolerances are required.

2. Versatility in Design

Laser cut polycarbonate provides designers with endless possibilities in terms of shape and design. The flexibility of the laser cutting process allows for the creation of intricate patterns, curves, and even 3D structures. This versatility opens up new avenues for creativity and innovation in various industries.

3. Clean and Smooth Cuts

The laser cutting process produces clean and smooth cuts on polycarbonate. Unlike traditional cutting methods, there is no physical contact between the cutting tool and the material, eliminating the risk of chipping or cracking. The result is a high-quality finish that requires minimal post-processing.

4. Time and Cost Efficiency

Laser cutting machine is a highly efficient process that saves both time and cost. The speed and accuracy of laser cutting machines allow for rapid production, reducing lead times and increasing productivity. Additionally, the non-contact nature of laser cutting eliminates the need for expensive tooling or setup changes, further reducing costs.

5. No Material Warping

Laser cutting, however, minimizes the risk of material warping due to its precise and localized heat application. This ensures that the final cut pieces maintain their original shape and dimensions.

Applications of Laser Cut Polycarbonate

Laser cut polycarbonate finds applications in a wide range of industries. Here are some notable examples:

1. Signage and Displays

Polycarbonate is a popular choice for creating signage and displays due to its transparency and durability. Laser cut polycarbonate allows for the precise cutting of letters, logos, and intricate designs, resulting in eye-catching and professional-looking signage.

2. Protective Shields and Covers

The impact resistance and high heat resistance of polycarbonate make it an excellent choice for protective shields and covers.

3. Automotive Components

The automotive industry benefits greatly from laser cut polycarbonate. The precise cutting capabilities of laser cutting ensure that these components fit perfectly and meet the industry’s stringent requirements.

4. Electronic Enclosures

Polycarbonate is widely used in the electronics industry for its electrical insulation properties. Laser cut polycarbonate can be used to create custom enclosures for electronic devices, ensuring proper protection and functionality.

5. Architectural Applications

The versatility of laser cutting allows for the creation of intricate patterns and designs, adding a unique aesthetic appeal to architectural structures.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.