Laser Knowledge

CO2 Laser Cutting Power, Thickness, Speed Chart

Understanding the relationship between laser power, material thickness, and cutting speed is essential for optimizing CO2 laser cutting operations. This comprehensive guide provides detailed cutting parameter charts for common materials, explains the factors affecting cutting performance, and offers practical guidance for selecting optimal settings.

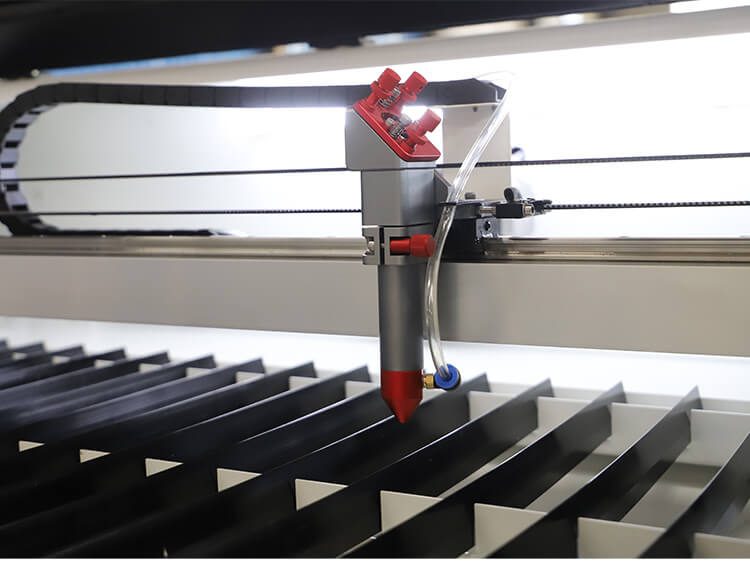

CO2 laser cutting relies on focused infrared laser energy (10.6 micron wavelength) to melt, burn, or vaporize materials along programmed cutting paths. The three critical parameters—laser power, material thickness, and cutting speed—interact to determine cut quality, edge finish, and production efficiency. Proper parameter selection ensures clean cuts, minimal heat-affected zones, and maximum productivity.

CO2 Laser Cutting

CO2 lasers can cut through materials of varying thicknesses at various speeds, depending on laser power, as well as material type and hardness. Higher power lasers are capable of cutting thicker materials at faster speeds. In most cases, CO2 laser cutters work with a power range of 40 watts to 300 watts to cut through wood with a thickness of 1 mm to 20 mm at a speed of 1000 mm/min to 9000 mm/min, acrylic with a maximum thickness of 40 mm at a speed of around 1200 mm/min, leather and cloth with a thickness of 0.75 mm to 10 mm at a speed of 500 mm/min to 12000 mm/min, and paper with a thickness of 0.5 mm to 11 mm at a speed of about 3000 mm/min.

Three core parameters determine cutting performance:

-

Laser Power (Wattage)

-

Material Thickness

-

Cutting Speed

These parameters are closely connected. Higher laser power allows thicker materials to be cut at higher speeds, while lower power requires slower speeds or thinner materials to achieve clean cuts.

CO2 Laser Power Explained

Laser power is measured in watts (W) and represents the energy output of the laser tube.

Common CO2 laser power levels include:

-

40W–60W: Entry-level machines for thin materials, engraving, and light cutting

-

80W–100W: Popular mid-range power for small workshops and signage production

-

130W–150W: Industrial-grade cutting for thicker acrylic and wood

-

200W+: Heavy-duty CO2 laser systems for high-speed, thick material cutting

Higher power does not always mean better results. The ideal power depends on material type, thickness, and production volume.

CO2 Laser Power, Thickness, and Speed Relationship

A simple rule applies:

Higher laser power = thicker cutting capability or faster cutting speed

However, optimal results come from balancing all three parameters. Increasing power without adjusting speed may reduce edge quality, while slowing speed too much can overheat the material.

Other important factors include:

-

Lens focal length

-

Air or gas assist pressure

-

Laser tube quality

-

Machine stability and motion system

Best CO2 Laser Cuttable Materials

Wood

• Solid wood (such as birch, poplar, red oak, cherry)

• MDF (medium-density fiberboard)

• Plywood

• Cork

Plastics

• Acrylic

• PP (polypropylene)

• PVC (polyvinyl chloride)

• ABS (acrylonitrile butadiene styrene)

Paper

• Paper Sheet

• Cardstock

• Cardboard

Leather & Fabric

• Organic fabrics (such as polyester)

• Line fabric (multi-layer)

• Artificial fabric (chemical fiber fabric)

• Leather (genuine leather and artificial leather)

Foam (Polystyrene)

• HIPS

• EPS

• XPS

CO2 Laser Cutting Thickness & Speed & Kerf Chart

| Material | Thickness (mm) | Speed (mm/min) | Assist Gas | Kerf (mm) |

|---|---|---|---|---|

| Organic Glass | 10 | 800 | N2 | 0.7 |

| Polyester Felt | 10 | 2600 | N2 | 0.5 |

| Line Fabric (Multi-layer) | 15 | 900 | N2 | 0.5 |

| Cardboard | 0.5 | 3000 | N2 | 0.4 |

| 2.6 | 3000 | N2 | 0.5 | |

| Quartz Glass | 1.9 | 600 | 0.2 | |

| PP (Polypropylene) Sheet | 5.5 | 700 | N2 | 0.5 |

| Polystyrene Sheet (HIPS, EPS & XPS Foam) | 3.2 | 4200 | N2 | 0.4 |

| PVC Sheet | 4 | 1700 | Air | N/A |

| Organic Glass | 10 | 1200 | ||

| Bakelite Board | 5 | 2100 | ||

| Fiberboard | 15.6 | 4500 | N2 | |

| Multi-layer Plywood | 6.2 | 9000 | ||

| PVC (Polyvinyl Chloride) Laminate | 3.1 | 10500 | ||

| Chipboard | 3.9 | 18000 | ||

| 3.1 | 22500 | |||

| Acrylamide Board | 2.8 | 33900 | ||

| 3.2 | 29700 | |||

| 3.2 | 29700 | |||

| Acrylic | 2.0 | 1000 | N/A | |

| Artificial Leather | 0.8 | 2500 | ||

| Gypsum Board | 9.0 | 500 | ||

| Plywood | 10.0 | 1100 | ||

| Heat-Resistant Glass | 2.2 | 500 | ||

| Rubber Sheet | 5 | 500 | ||

| Leather | 4 | 2200 | ||

| Artificial Fabric | 6.5 | 2200 |

CO2 Laser Power and Cutting Thickness Chart

| Material | Laser Power | ||||

|---|---|---|---|---|---|

| 40W | 50W | 60W | 80W | 100W | |

| Cutting Thickness | |||||

| Acrylic | 3mm | 5mm | 5-8mm | 6-10mm | 10-12mm |

| MDF | 1mm | 2mm | 4mm | 5mm | 6mm |

| Plywood | 3mm | 5mm | 8mm | 10mm | 13mm |

| PVC | 2mm | 3mm | 4mm | 5mm | 8mm |

| Rubber | 2mm | 2mm | 3mm | 4mm | 5mm |

| Leather | 2mm | 3mm | 4mm | 5mm | 7mm |

| Fabric | 2mm | 3mm | 4mm | 6mm | 7mm |

| Paper | 3mm | 4mm | 5mm | 7mm | 8mm |

| Material | Laser Power | ||||

|---|---|---|---|---|---|

| 130W | 150W | 180W | 220W | 300W | |

| Cutting Thickness | |||||

| Acrylic | 12-25mm | 17-28mm | 20-30mm | 20-35mm | 20-40mm |

| MDF | 8mm | 10mm | 10mm | 12mm | 18mm |

| Plywood | 15mm | 15mm | N/A | N/A | N/A |

| PVC | 9mm | 10mm | N/A | N/A | N/A |

| Rubber | 6mm | 7mm | N/A | N/A | N/A |

| Leather | 8mm | 10mm | N/A | N/A | N/A |

| Fabric | 8mm | 10mm | N/A | N/A | N/A |

| Paper | 10mm | 10mm | N/A | N/A | N/A |

All charts are for reference only. The actual cutting thickness will vary depending on material properties and cutting parameters such as power and speed.

Conclusion

A clear understanding of CO2 laser cutting power, thickness, and speed helps manufacturers improve cutting quality, reduce waste, and maximize efficiency. By selecting the correct laser power and optimizing cutting speed for each material, users can achieve clean edges, consistent results, and higher productivity.

Whether you are upgrading equipment or fine-tuning your current CO2 laser cutter, using a reliable power–thickness–speed chart is the key to professional cutting performance.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.