Buyer Guide

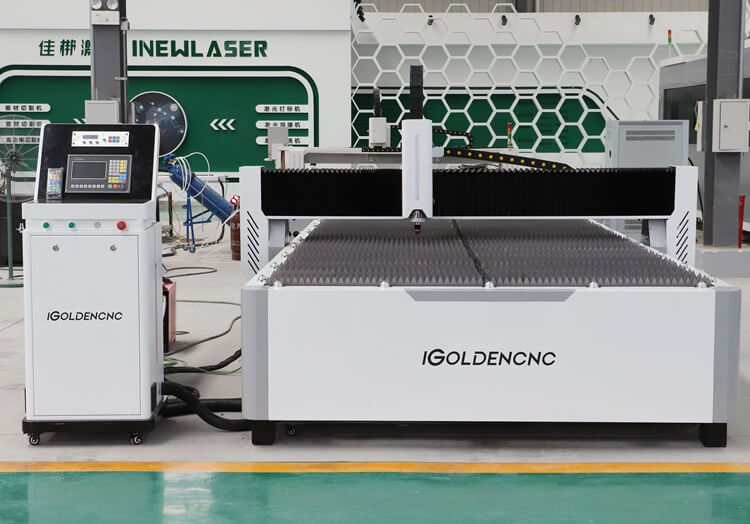

CNC Plasma Cutter for Sheet Metal Manufacturing

A CNC plasma cutter is capable of cutting most metallic materials, including ferrous and non-ferrous metals, such as iron, carbon steel, structural steel, stainless steel, tool steel, brass, copper, bronze, aluminum, titanium and their alloys to shape metal sheets, rods, strips, square and round tubes, as well as manufacturing a variety of metal profiles.

CNC Plasma Cutter for Sheet Metal

CNC plasma cutting machines are used in a range of metal fabrication industries such as automobile manufacturing and welding workshops, auto repair and restoration shops, machine tool manufacturing, industrial machinery factories, shipbuilding manufacturers, mining machinery workshops, power facilities plants, construction sites, aerospace manufacturing centers.

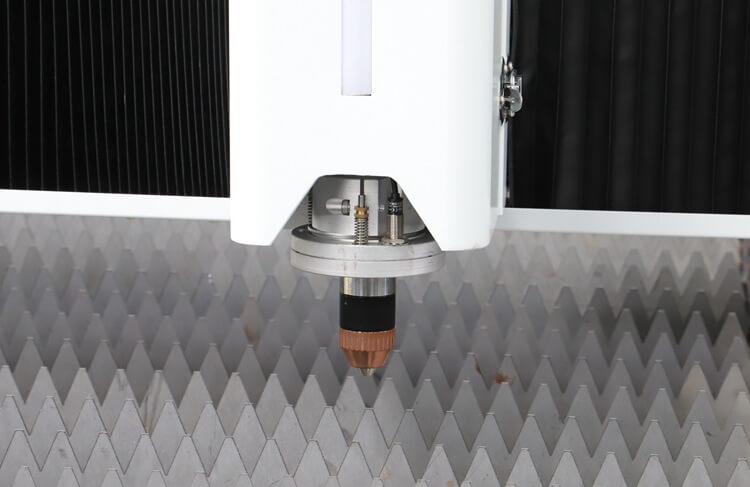

A plasma cutter is a type of thermal metal cutting tool that uses high velocity plasma or ionized gas to cut through metal, and blow away the molten metal with high-speed airflow at the same time to form a narrow plasma cut seams.

It is used to cut various metals, like carbon steel, stainless steel, copper, aluminum, cast iron, and more. It makes it possible to cut through electrically conductive metals with precision. It features with high cutting speed, thin cut seams, low deformation, small heat-affected zone, easy-to-use, and energy saving. With the pilot arc, it will generate a low power plasma arc in the air, which make the cut with lower cost.

It is used for sheet metal fabrication, metal structure making, machinery building, repair shop, drilling, digging, beveling, patching and more metal cutting projects & plans.

What Are The Types of Plasma Cutters?

The most common types of plasma cutters include the handheld and CNC variant (hobby types and industrial types). The most common power supplies include Huayuan power supply and Hypertherm power supply.

According to the working methods, the kits can be divided into air kits, dry kits, semi-dry kits and underwater kits.

According to the cutting quality and precision, you will meet the types of ordinary, fine, laser-like, and so on.

According to the appearances, the three types are listed bellow:

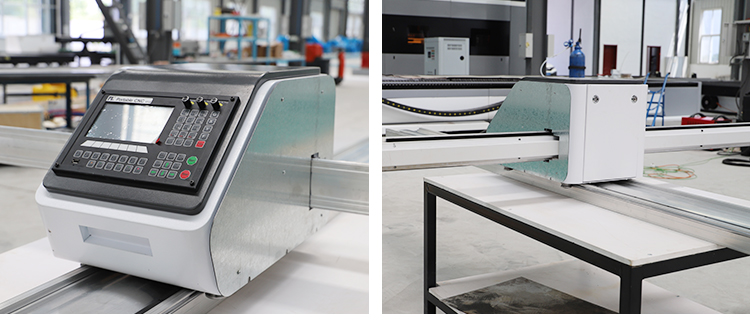

Portable CNC Kits

The machine is portable, easy to setup, compact in structure, small in space and low in manufacturing cost. However, due to the limitation of the cantilever structure, the stress conditions are poor, the transverse deformation is prone to occur, the transverse cutting width is limited, and the rigidity is poor during high-speed machining.

Gantry CNC Kits

The gantry-type supporting method is bidirectionally supported, the force is more uniform, the equipment has good rigidity, and can achieve a large lateral span, usually up to 3 to 10m. However, the equipment installation requirements are high, the structure is relatively large, and it takes up more plant area. The driving mode is divided into unilateral driving and bilateral driving. Unilateral drive and bilateral drive each have their own characteristics and applications. The unilateral drive avoids the high-precision synchronous control and complicated structure of the bilateral drive. However, due to the offset of the center of mass and the driving force does not pass through the center of mass, asymmetric inertial force will be generated during operation, which is prone to vibration, deformation and tilt. Therefore, it can only be used in a small span. The double-sided drive structure is relatively complicated and requires high-precision synchronous control on both sides, which can be used for a larger span and more stable movement.

CNC Table Kits

The cutting part and the machine are integrated, which is convenient to move in place, but the movement range of the cutting torch is relatively small, and the cutting width is subject to certain restrictions.

What is CNC plasma cutter used for?

What materials can CNC plasma cutting machine cut? CNC plasma cutting machines are used to cut metals, such as sheet metal, stainless steel, galvanized steel, square and round tubes, including iron, el, hot rolled steel, cold rolled steel, carbon steel, alloy, bronze, aluminum, copper, brass, and titanium. CNC plasma cutting machines are widely used in machine tool manufacturing, petrochemical equipment, light industrial machinery, pressure vessels, ships, mining machinery, electric power, bridge construction, aerospace, steel structure and other industries. Enthusiasts, family stores, family businesses, small stores, small businesses, school education, industrial manufacturing.

Key Features of CNC Plasma Cutter for Sheet Metal Manufacturing

- Precision and Accuracy: CNC plasma cutters can achieve high levels of precision and accuracy in cutting intricate shapes and designs. The computer-controlled system ensures consistency and eliminates human error, resulting in clean and precise cuts.

- Flexibility: CNC plasma cutters offer a high degree of flexibility. They can cut through a wide range of sheet metal thicknesses, from thin gauge sheets to thicker materials. This versatility makes them suitable for various applications in sheet metal manufacturing.

- Speed and Efficiency: Plasma cutting is generally faster compared to traditional cutting methods such as manual sawing or shearing. CNC plasma cutters can rapidly move across the sheet, resulting in increased productivity and reduced manufacturing time.

- Cost-Effectiveness: While CNC plasma cutters require an initial investment, they can be cost-effective in the long run. The automated nature of the process reduces labor costs and minimizes material wastage. Additionally, the ability to optimize cutting paths helps maximize material usage.

- Complex Shape Cutting: CNC plasma cutters excel at cutting complex shapes and intricate designs. They can easily handle curves, angles, and bevels, allowing for the production of intricate sheet metal components and parts.

- Integration with CAD/CAM Software: CNC plasma cutters can integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This enables seamless transfer of digital designs to the machine, facilitating precise and automated cutting based on the specified patterns or drawings.

- Scalability: CNC plasma cutters are available in various sizes and configurations, allowing for scalability to match different production requirements. Whether you have a small-scale operation or a large manufacturing facility, there are CNC plasma cutting systems available to suit your needs.

- Minimal Heat-Affected Zone: Plasma cutting generates a narrow heat-affected zone (HAZ) compared to other thermal cutting methods. This reduces the risk of warping or distorting the sheet metal during the cutting process, ensuring better dimensional accuracy and preserving the material’s structural integrity.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.