Laser Knowledge

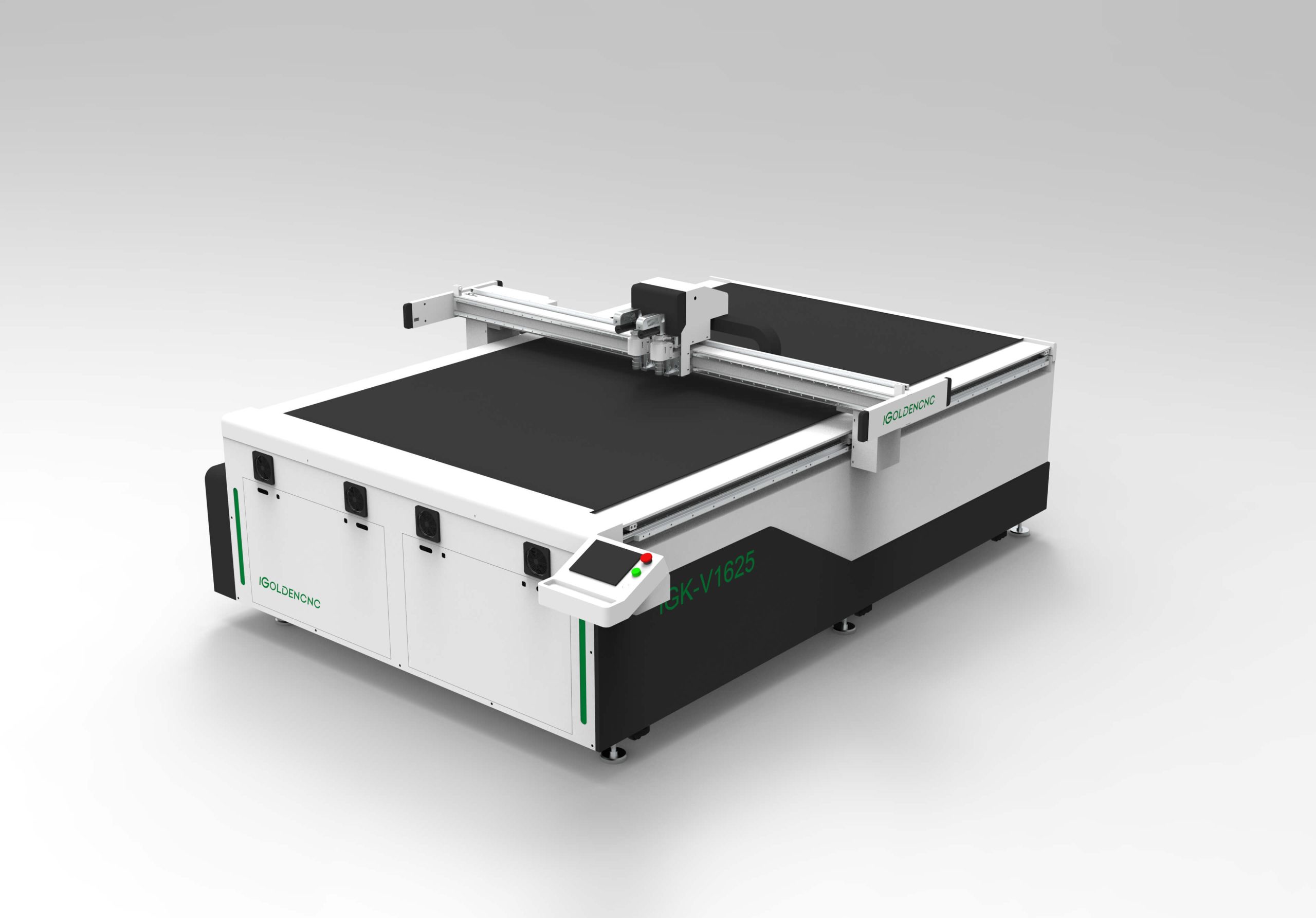

CNC Leather Cutting Machine for Shoe Manufacturing

Transform your shoe manufacturing process with our advanced CNC leather cutting machine featuring state-of-the-art vibrating knife technology. Designed specifically for footwear industry professionals, this precision cutting system delivers unmatched accuracy, efficiency, and versatility for all your leather processing needs.

CNC Leather Cutting Machine for Shoe

Accuracy in dimensions and processing are extremely important to improve quality and finishing for both small and large leather goods. Close to its production capacity and reliability, such an accuracy has made IGOLDEN become the most important partner of leather goods manufacturers.

IGOLDEN digital leather cutting machines eliminate the need for expensive dies and reduce the need for manpower, all while processing leather, sole, lining, and pattern materials efficiently and at the highest levels of quality. Superior cutting performance, low operating costs, and optimized workflow guarantee a quick return on investment.

Key Features & Benefits Leather Cutting Machine

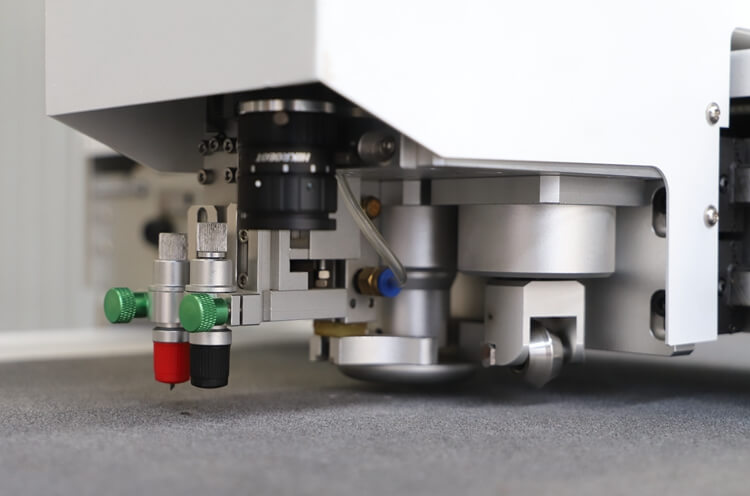

Precision Vibrating Knife Technology

Our vibrating knife cutting system utilizes high-frequency oscillation to achieve clean, precise cuts through various leather thicknesses. The advanced blade technology ensures minimal material waste while maintaining superior edge quality, essential for premium shoe production.

Advanced CNC Control System

The computer numerical control (CNC) system provides exceptional accuracy and repeatability. Program complex cutting patterns once and execute them flawlessly across thousands of pieces, ensuring consistent quality in every production run.

Versatile Material Compatibility

- Genuine leather (all grades and thicknesses)

- Synthetic leather and PU materials

- Fabric linings and textiles

- Rubber compounds

- Foam padding materials

High-Speed Production Capability

Maximize your manufacturing efficiency with cutting speeds up to 1200mm/min, significantly reducing production time while maintaining precision standards demanded by modern footwear manufacturing.

Technical Specifications

Cutting Area: Available in multiple sizes (1200x800mm, 1600x1000mm, 2000x1500mm) Cutting Thickness: Up to 25mm for leather materials Cutting Accuracy: ±0.1mm precision Software Compatibility: CAD/CAM integration with major design software Power Requirements: 380V/50Hz or customizable to regional standards

Industry Applications Leather Cutting Machine for Shoe

Footwear Manufacturing

Perfect for cutting shoe uppers, soles, linings, and decorative elements with consistent precision. Ideal for both small-batch custom orders and large-scale production runs.

Automotive Leather Goods

Excellent for automotive interior components, seats, and trim pieces requiring precise leather cutting.

Leather Goods Production

Suitable for handbags, wallets, belts, and other leather accessories requiring clean, professional cuts.

Why Choose Our CNC Leather Cutting Solution?

Our vibrating knife leather cutting machine represents the perfect balance of precision, speed, and reliability. With over a decade of experience in industrial cutting solutions, we understand the unique challenges facing shoe manufacturers today.

Professional Support: Comprehensive training, installation, and ongoing technical support Customization Options: Tailor the system to your specific production requirements Quality Guarantee: Backed by industry-leading warranty and service commitment

Investment in Your Future

Upgrade your leather cutting capabilities with technology that pays for itself through increased efficiency, reduced waste, and superior product quality. Our CNC leather cutting machines are trusted by leading footwear manufacturers worldwide.

Contact us today for a personalized consultation and discover how our vibrating knife cutting technology can revolutionize your shoe manufacturing process.

Competitive Advantages

Cost-Effective Production: Reduce material waste by up to 15% compared to traditional cutting methods Enhanced Quality Control: Eliminate human error with automated precision cutting Faster Time-to-Market: Rapid prototyping and production capabilities User-Friendly Operation: Intuitive software interface requires minimal training Reliable Performance: Industrial-grade components ensure consistent operation

| Material | digital cutter efficiency | Manual cutting efficiency | Instead of manual quantity |

| Imitation wool hat | 500mm/s | 100mm/s | 3 pepole |

| Imitation sweater collar | 500mm/s | 100mm/s | 3 pepole |

| Faux fur sleeves | 500mm/s | 100mm/s | 3 pepole |

| Faux wool vest | 300 sets | 100 sets | 3 pepole |

| Slippers (plush) | 400-500 sets | 200 sets | 3-4 pepole |

| Brushed | 100mm/s | 15mm/s | 2-3 pepole |

| Tufting | 90mm/s | 10mm/s | 2-3 pepole |

| Wool | 80mm/s | ≤10mm/s | 2-3 pepole |

| Short plush | 500-800mm/s | 100-150mm/s | 2-3 pepole |

| Sheep shearing | 500-800mm/s | 100-150mm/s | 2-3 pepole |

| Coral fleece | 500-800mm/s | 100-150mm/s | 4 pepole |

| Wool blend | 300mm/s | 50mm/s | 2-3 pepole |

| Fur sheep shearing | 500 sets | 80 sets | 2-3 pepole |

| Fur leather | 300 sets | 80 sets | 4 pepole |

| Fur clothing | 400 sets | 50 sets | 8 pepole |

| Fur coat | 300 sets | 100 sets | 3 pepole |

| Fur top | 300 sets | 100 sets | 3 pepole |

| Fur Hat | 1500 sets | 500 sets | 3 pepole |

| Fur collar | 3000 sets | 700 sets | 4 pepole |

| Fur | 200 sets | 50 sets | 4 pepole |

| Plush | 800-1000m/s | 100-200mm/s | 4 pepole |

| Fur collar plush | 200 sets | 50 sets | 2-3 pepole |

| Faux fur | 500-800mm/s | 100-150mm/s | 2-3 pepole |

| The above data is for reference only, the actual operation, affected by the thickness, hardness, flexibility, etc. of the material, the data will be biased. | |||

Advantages

The textile industry has undergone tremendous changes since its inception. With the integration of advanced technologies in recent years and the use of automated cutting machines in the production process, the textile industry offers countless applications and expands possibilities. Apparel textile CNC cutting can perfectly finish the material and avoid wear and tear problems, especially for synthetic materials.

1) Precision and accuracy: CNC cutting machines adopt computer control systems to ensure precise cutting of textile materials. This helps minimize material waste and improve overall product quality.

2) Special-shaped pattern cutting: It can complete pattern cutting that is difficult and complex in style and cannot be achieved by die-cutting machines.

3) Efficient material utilization: The precision of CNC cutting ensures the best utilization of materials, and the use of nesting software can save 30% of materials.

4) Efficient production of one-offs and small batches: Integrated digital production workflows significantly reduce unit costs. Our tool’s conversion is fast and largely automatic. This allows you to produce single-piece products as cost-effectively as mass production. It is 3-5 times that of manual efficiency.

5) Production consistency: CNC cutting machines can ensure the consistency of cutting patterns and sizes of large batches of clothing. Cutting edges are neat and burr-free, which helps maintain a high level of product quality and consistency.

6) Versatility: CNC cutting machines can handle a variety of fabrics and materials, from delicate silk to heavy denim, making them suitable for different types of clothing.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.