Laser Knowledge

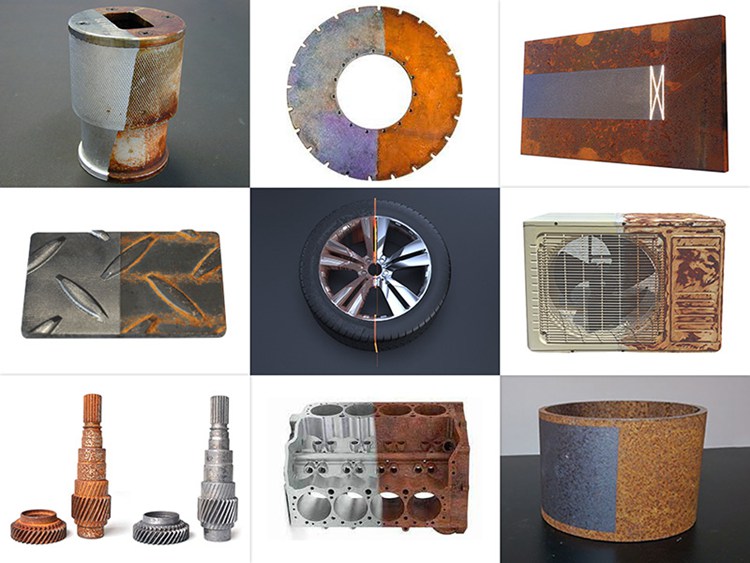

Cars Laser Rust Removal, Oil Stain Removal, and Paint Removal Tools

A laser cleaning machine is a tool that utilizes laser technology to remove contaminants, coatings, rust, paint, and other unwanted materials from surfaces. These machines have gained popularity in various industries, including automotive, aerospace, conservation, and manufacturing, due to their precision and environmental advantages compared to traditional cleaning methods.

Car Laser Cleaning for Rust Removal

Laser technology has been explored for various applications in the automotive industry, including rust removal, oil stain removal, and paint removal. While laser-based tools for these purposes are still in development and not widely available on the market as of my knowledge cutoff in September 2021, I can provide you with some information on the potential use of lasers for these tasks:

- Oil Stain Removal: Laser technology has the potential to remove oil stains from various surfaces, including automotive components. By focusing laser energy on the oil stain, it can be heated and vaporized, effectively removing it. However, the effectiveness of laser oil stain removal depends on factors such as the type and thickness of the oil, the surface material, and the laser parameters.

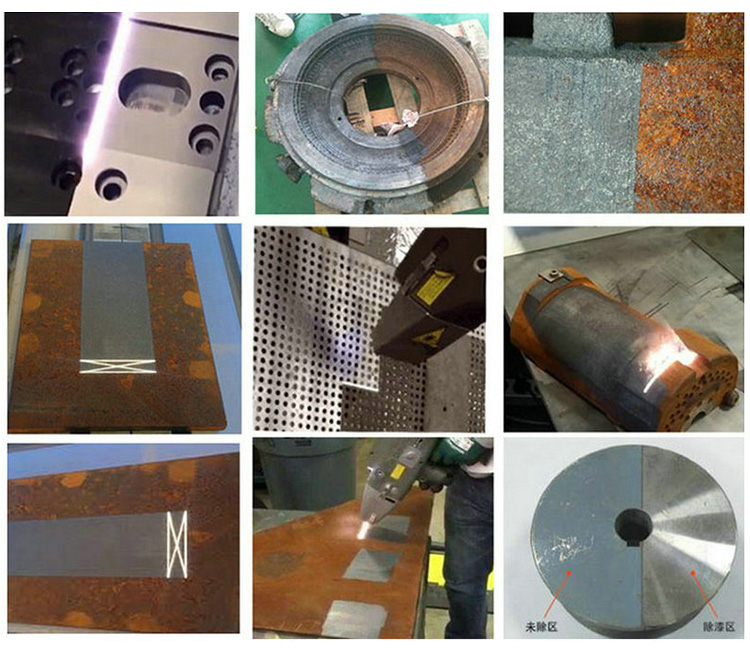

- Paint Removal: Laser technology has been explored for paint removal in the automotive industry. By directing a laser beam at the painted surface, the energy can selectively heat and vaporize the paint, allowing for its removal. Laser paint removal offers advantages such as precision, reduced dust and fumes, and the ability to remove paint from complex shapes. However, the effectiveness of laser paint removal depends on factors such as the type of paint, the substrate material, and the laser parameters.

- Laser Rust Removal: Laser technology has shown promise in removing rust from metal surfaces. A high-powered laser can be used to vaporize or ablate the rust layer, leaving behind a clean surface. Laser rust removal offers advantages such as precision, non-contact operation, and minimal impact on the underlying metal.

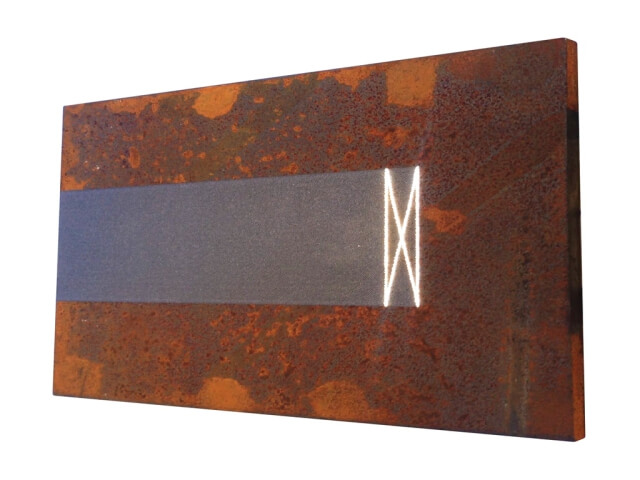

Rust Removal: Laser cleaning machines can effectively remove rust from metal surfaces without causing damage to the underlying material.

Paint Stripping: These machines are used for removing paint layers from surfaces, providing a precise and efficient method.

Coating Removal: Laser cleaning is employed to remove various coatings, such as oils, grease, and protective films, from surfaces.

Advantages:

Environmentally Friendly: Laser cleaning is often considered environmentally friendly as it eliminates the need for chemicals and reduces waste.

Precision: The process is highly controllable, allowing for selective cleaning and minimal impact on the substrate.

Reduced Operator Exposure: Compared to traditional methods involving chemicals or abrasive materials, laser cleaning reduces the operator’s exposure to potentially hazardous substances.

Non-contact Cleaning: Laser cleaning is a non-contact method, reducing the risk of damage to the substrate. It is particularly useful for sensitive materials and intricate surfaces.

Laser Source:

Fiber Lasers: These are commonly used in laser cleaning machines. Fiber lasers offer high power, efficiency, and flexibility, making them suitable for various applications.

Pulsed Lasers: Many laser cleaning systems use pulsed lasers to deliver short bursts of high-intensity laser energy. This helps prevent damage to the substrate and allows for better control over the cleaning process.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.